Assembled steel beam overall stability testing concentrated load loading device and method

A technology of stability test and concentrated load, which is applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc. The problem that the device cannot be solved, etc., achieves the effect of reducing the load action area, wide applicability of the section, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with embodiment.

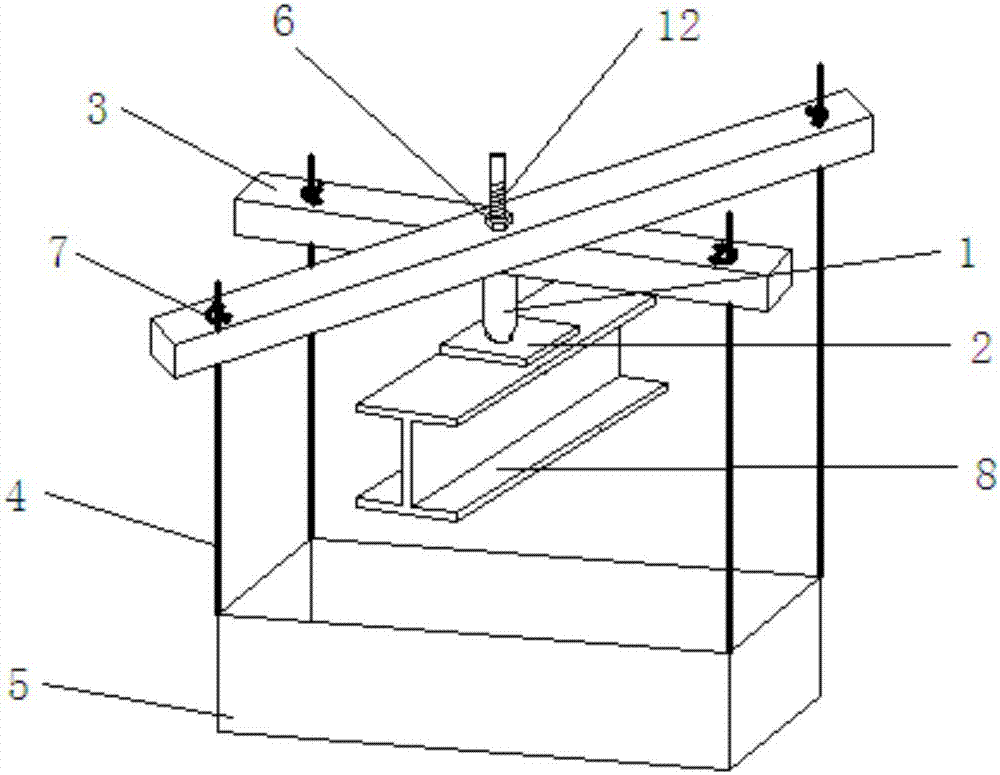

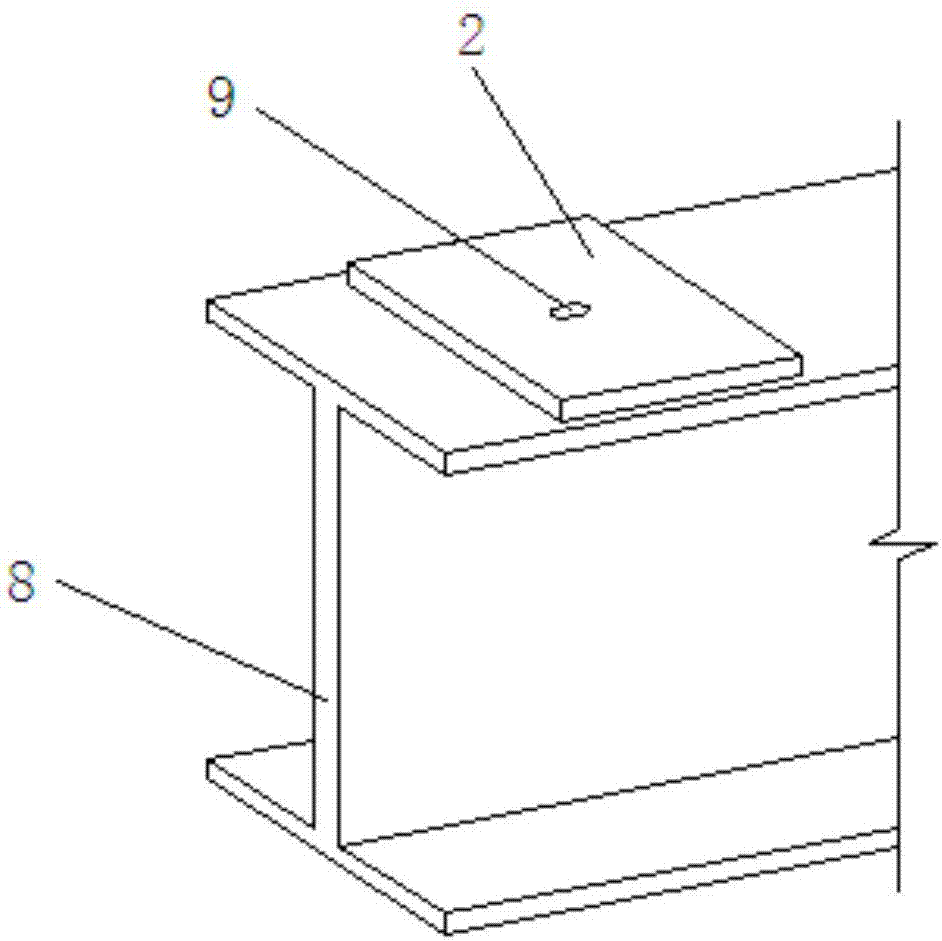

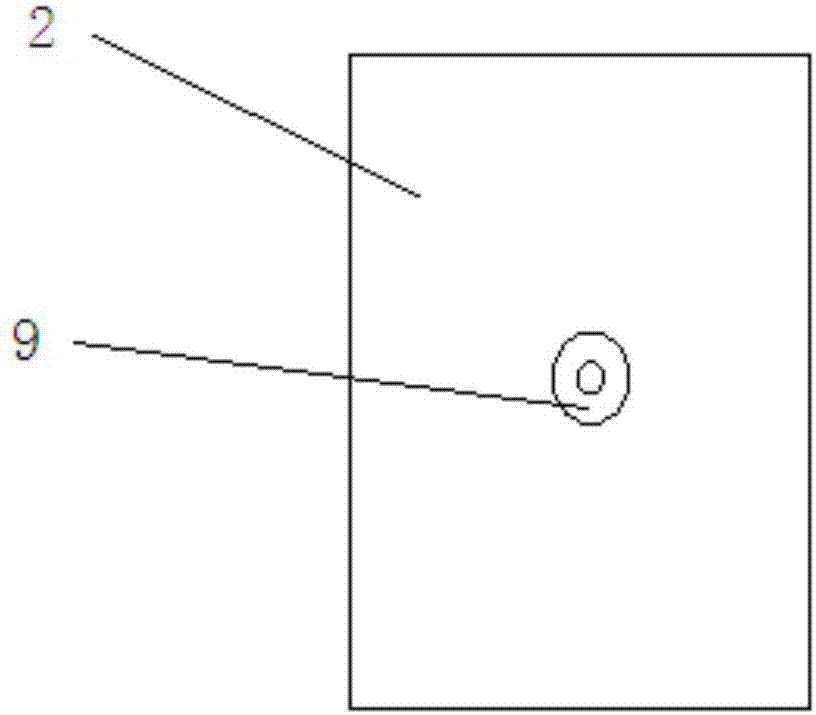

[0035] according to Figure 1 ~ Figure 2As shown, a kind of assembly-type steel beam overall stability test concentrated load loading device provided by the present invention comprises a loading taper nail 1, a loading plate 2, a square steel pipe 3, a steel strand 4 and a loading box 5, two square steel pipes 3 are overlapped and superimposed to form a cross shape, and the angle between the two square steel pipes 3 can be adjusted as required, and a first through hole (not shown) is provided at the overlap of the two square steel pipes 3, And the square steel pipe 3 is a hollow steel pipe, the loading cone nail 1 is inserted in the first through hole, the first through hole is a circular through hole, and its diameter is larger than the end of the loading cone nail 1 diameter, so that the end of the loading taper 1 can fully extend into the first through hole, the outer w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com