Circular lithium battery and production method thereof

A lithium battery, circular technology, applied in the field of circular lithium batteries, can solve the problems of complex preparation and installation process, affect the effect of current extraction, reduce the welding area, etc., to improve the yield rate, save the liquid injection hole sealing process, Guarantee the effect of overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

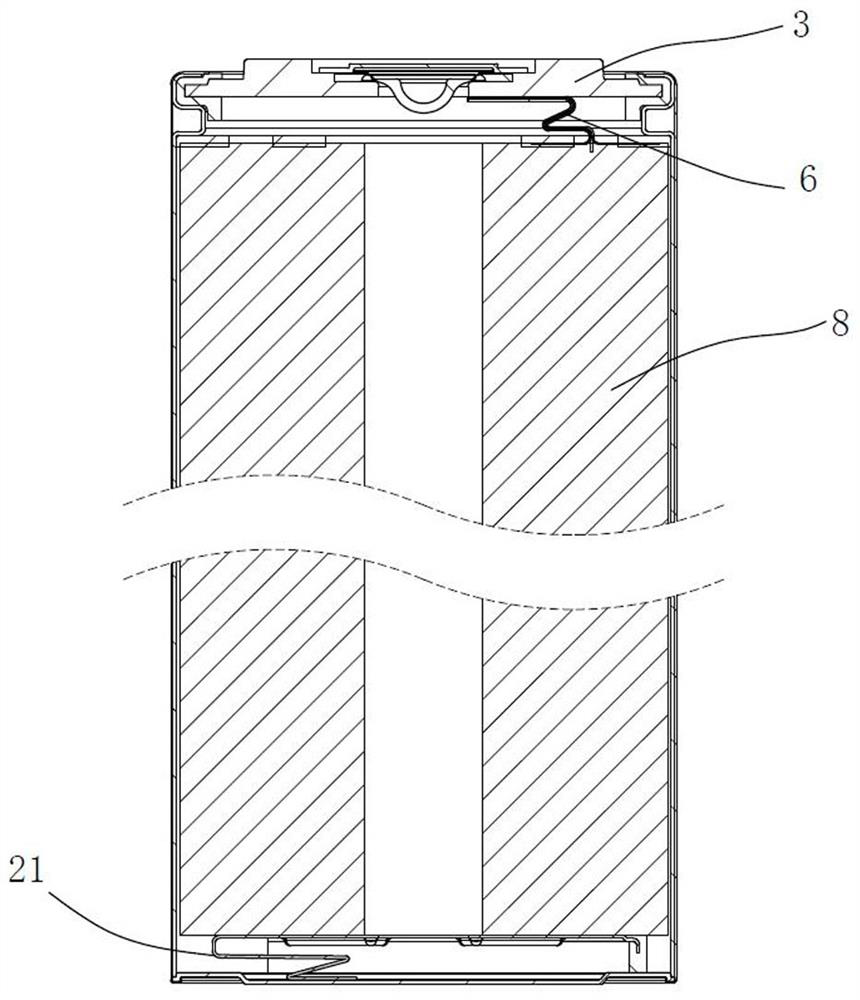

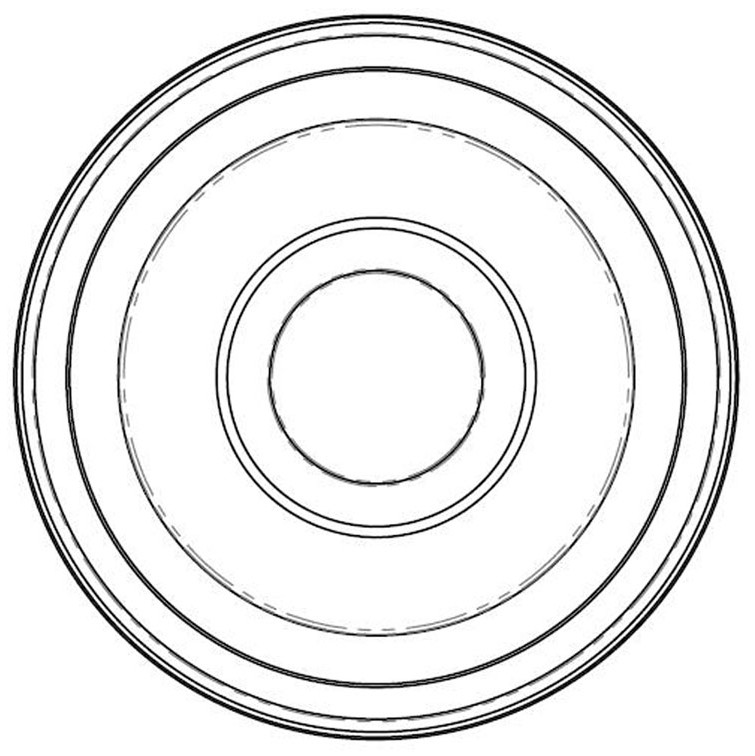

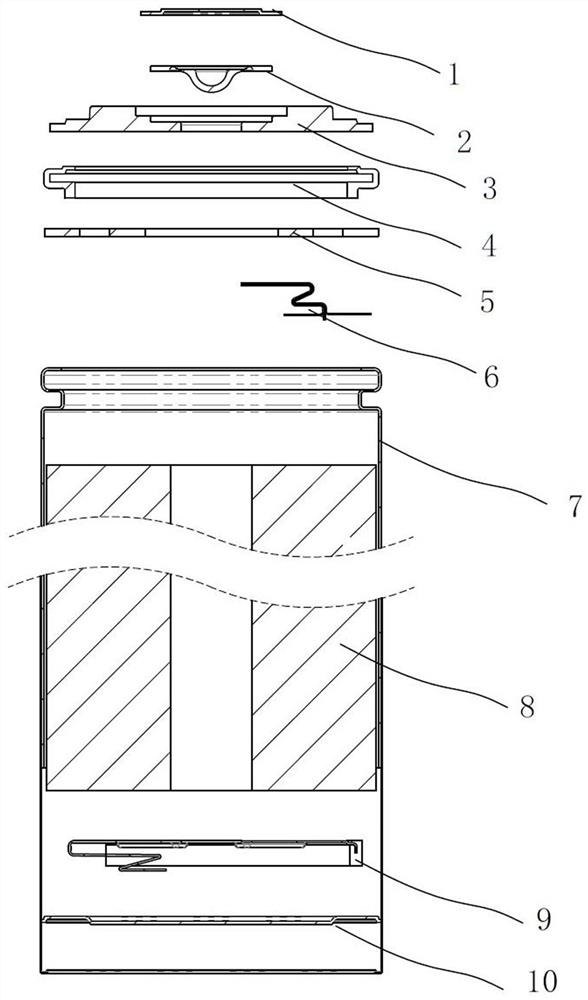

[0050] Embodiment 1: see attached figure 1 to attach image 3 As shown, a circular lithium battery includes a casing 7, a cell 8, a positive battery cover assembly and a negative battery cover assembly. The shell 7 adopts a stainless steel round tube, and the electric core 8 is located inside the shell 7 .

[0051] see Figure 4 with Figure 5 The electric core 8 includes a positive electrode foil 11, a negative electrode foil 12 and a separator 13, and the positive electrode foil 11 and the negative electrode foil 12 are separated by the separator 13 and wound into a cylindrical shape; A positive pole tab 6, an insulating gasket 5 is provided between the battery cell 8 and the positive battery cover plate assembly; the lower end of the battery cell is not aligned, and the order from short to long is the positive electrode foil 11, the separator 13, and the negative electrode foil. 12. The extended part of the negative electrode foil 12 is pressed and covered on the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com