Switch power supply integrated chip board card layout structure

A technology of integrated chip and switching power supply, which is applied in the direction of printed circuit components, etc., can solve the problems of small contact area between the heat sink and the printed circuit board, the temperature rise of the integrated chip of the switching power supply, and the reduction of the working efficiency of the integrated chip of the power supply. Effect of temperature, reduction of electricity cost, and reduction of power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the accompanying drawings and specific examples. The following examples are to explain the present invention, but the present invention is not limited to the following embodiments.

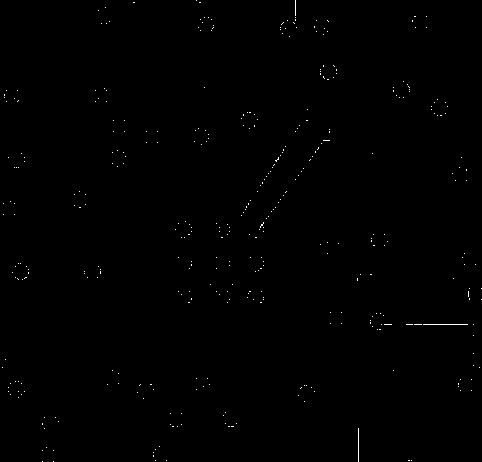

[0017] like figure 1 and 2 As shown, the layout structure of the switching power supply integrated chip board card provided by this embodiment includes a printed circuit board, a front GND network is established on the front of the printed circuit board, and at least five via holes 2 are set on the front GND network. Preferably, this implementation In the example, nine vias 2 are punched on the front GND network to ensure overcurrent capability. The backside GND network 3 is laid on the backside of the printed circuit board to increase the heat dissipation area of the switching power supply integrated chip.

[0018] When using, solder the heat sink 1 on the front GND network, and the size of the front GND network ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com