Connector with built-in mounting holes

A technology of mounting holes and connectors, applied in vehicle connectors, connections, conductive connections, etc., can solve the problems of long matching stroke and large size requirements of mounting flanges, and can ensure the fixing and overcurrent capacity and reliability. , to avoid the effect of sealing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

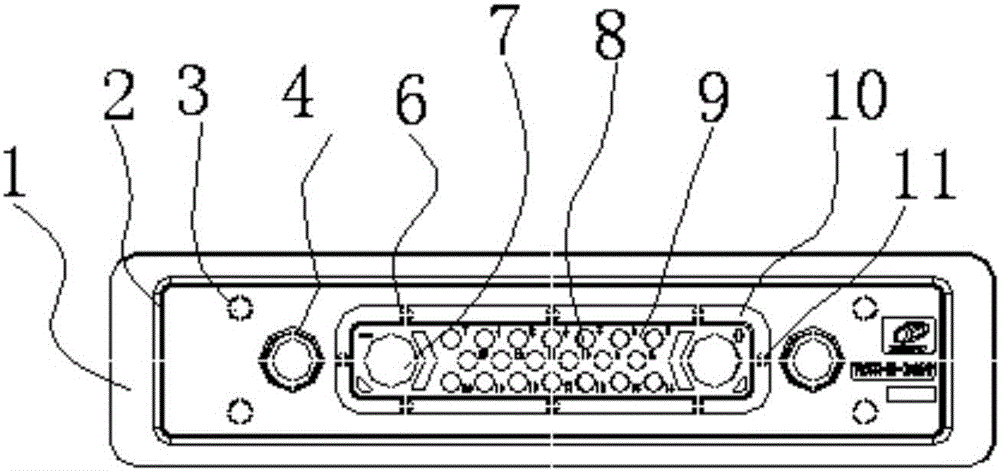

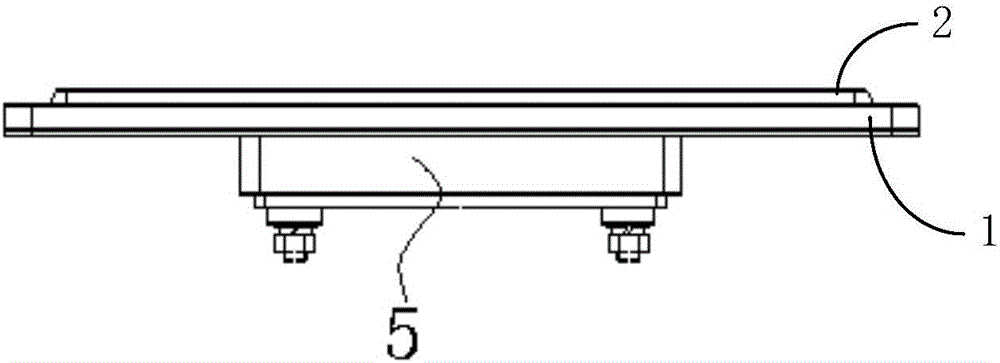

[0031] figure 1 A schematic structural diagram of a connector with a built-in mounting hole provided by Embodiment 1 of the present invention. Such as figure 1 As shown, it includes a main body 1, the main body 1 has a rectangular structure and is provided with a rectangular groove. . The inside of the annular boss 2 is provided with a screw hole 3 and a guide sleeve 4, the number of the screw holes 3 is 4, the screw hole 3 is used for installation and fixing, and the guide sleeve 4 is used for matching and positioning with the other end to meet For the accurate connection of the large and small contact pieces 8, it should be noted that the height of the guide sleeve 4 is not higher than the height of the annular boss 2 on the main body 1. The center of the main body 1 is provided with a contact cavity 5 . A threaded hole 6 is provided around the contact cavity 5, and a large contact 7 and a small contact 8 are arranged inside the contact cavity 5, and the large contact 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com