Method for installing stiffening beam of suspension bridge over navigable river and swing shift system used in method

An installation method and technology for suspension bridges, applied in the field of swaying systems, can solve problems such as poor economy and operating efficiency, long construction period of suspension bridges, and huge structural system, and achieve the effects of shortening the construction period, low cost, and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

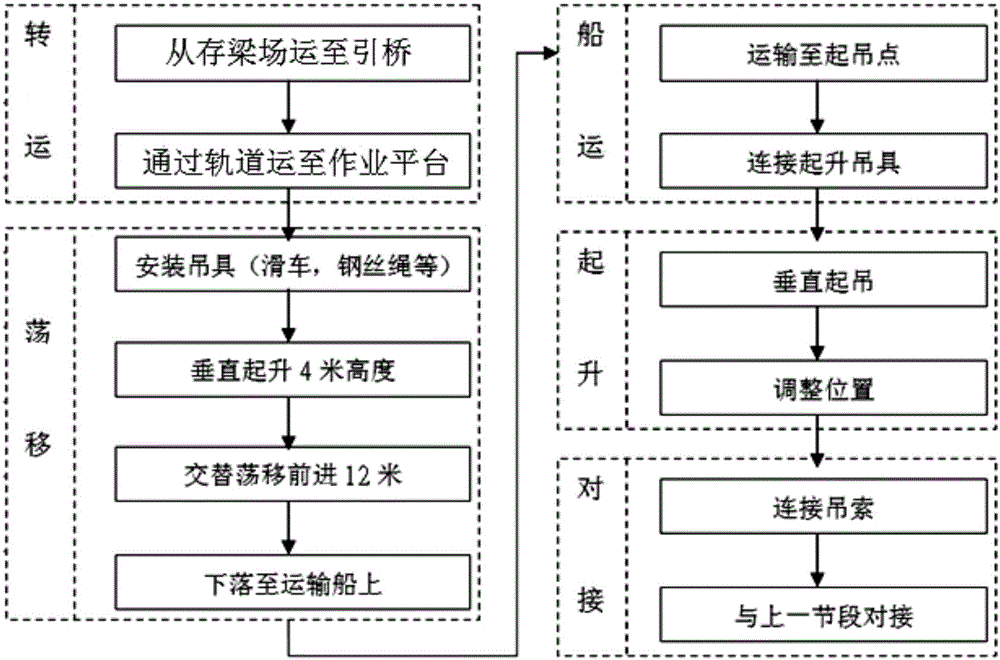

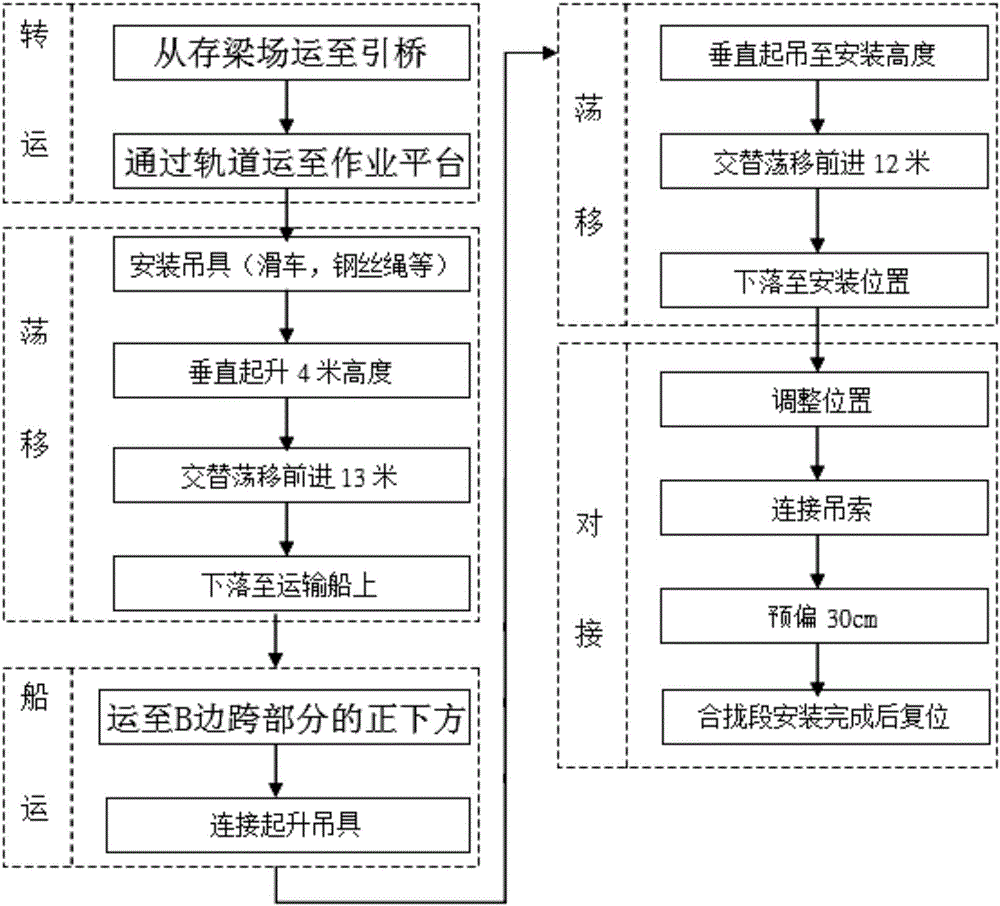

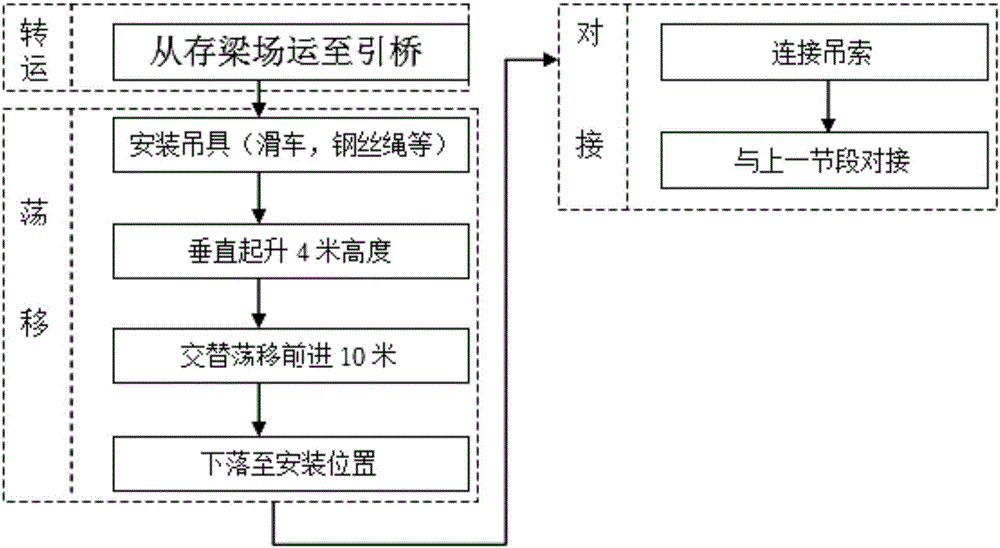

[0034] The invention relates to a method for installing a stiffening beam of a suspension bridge on a river.

[0035] Among them, the stiffening beam of the suspension bridge is usually mainly composed of the main truss, the upper and lower parallel, and the transverse truss. The stiffened beam adopts integral node technology, and each member of the stiffened beam is a factory weldment. In order to reduce the on-site assembly and connection of the stiffened beam members, the chord and one or two nodes are welded into a whole in the factory, and high-strength bolts are used on site. Connected into trusses. The stiffening beams of the whole bridge are divided into dozens of sections, and the weight of each section is as high as tens of tons; the stiffening beams of each section are usually assembled in the assembly yard of the construction site.

[0036] The river targeted by the present invention is a river with navigable capability.

[0037] The design structure of the suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com