Assembling process of electrode insulating sealing structure

A technology of sealing structure and assembly process, applied in the direction of structural parts, circuits, electrical components, etc., can solve the problems of the influence of the insulation sealing performance of the insulating sealing body, the long assembly process, and the failure of the insulation sealing, so as to simplify the assembly process and solve the problems of the assembly process. The effect of long process, guaranteed reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

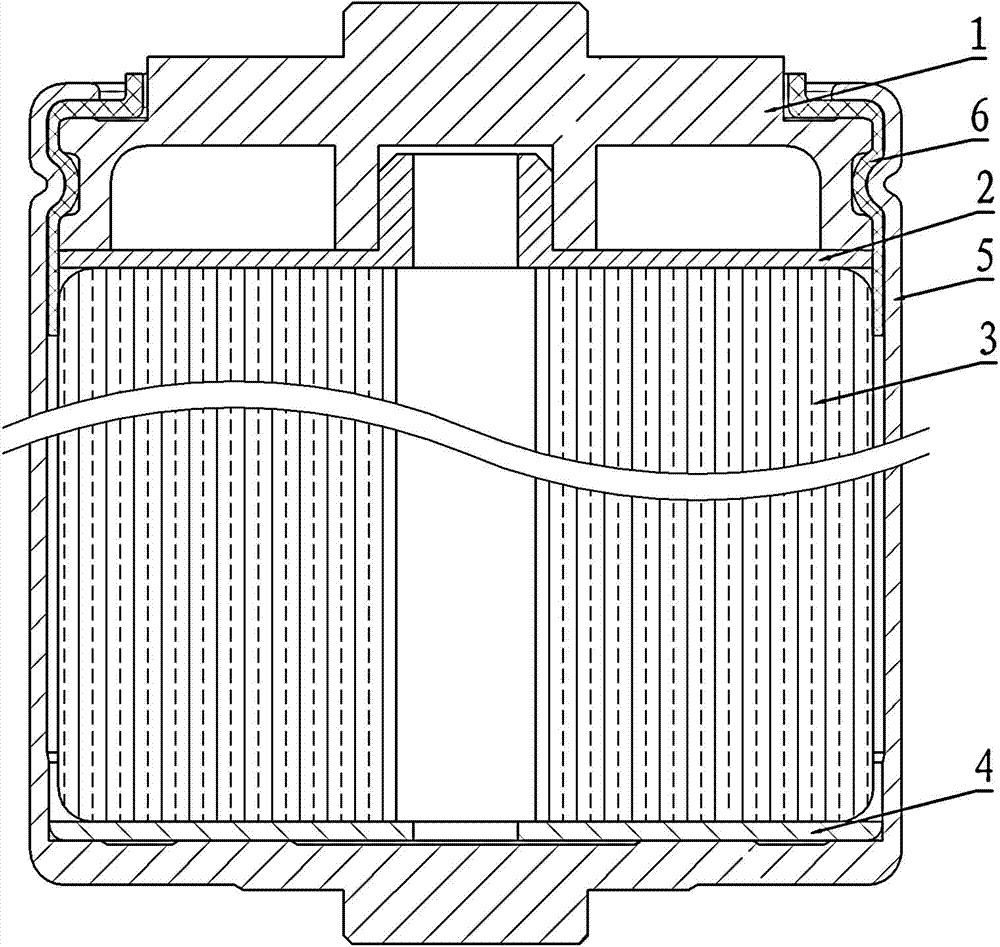

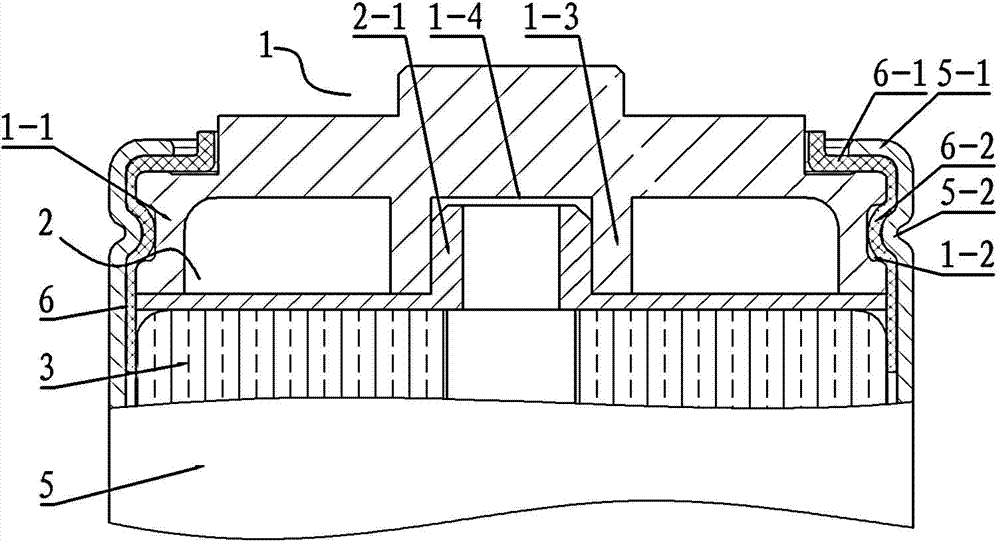

[0033] In an embodiment of the assembling process of the electrode insulating sealing structure of the present invention, the assembling process of the electrode insulating sealing structure is composed of the following steps: Step 1, pressing or knocking the positioning protrusion provided on one of the end cap and the current collecting plate. In another set positioning hole, so that the positioning hole and the positioning protrusion are transitionally mated together, and a joint portion is provided at the joint position of the end cover and the end face of the current collecting plate at the periphery of the positioning hole and the positioning protrusion;

[0034] In step 2, welding is performed on the joint portion to weld and connect the end cap and the current collecting plate to form an electrode lead-out structure at the end of the cell.

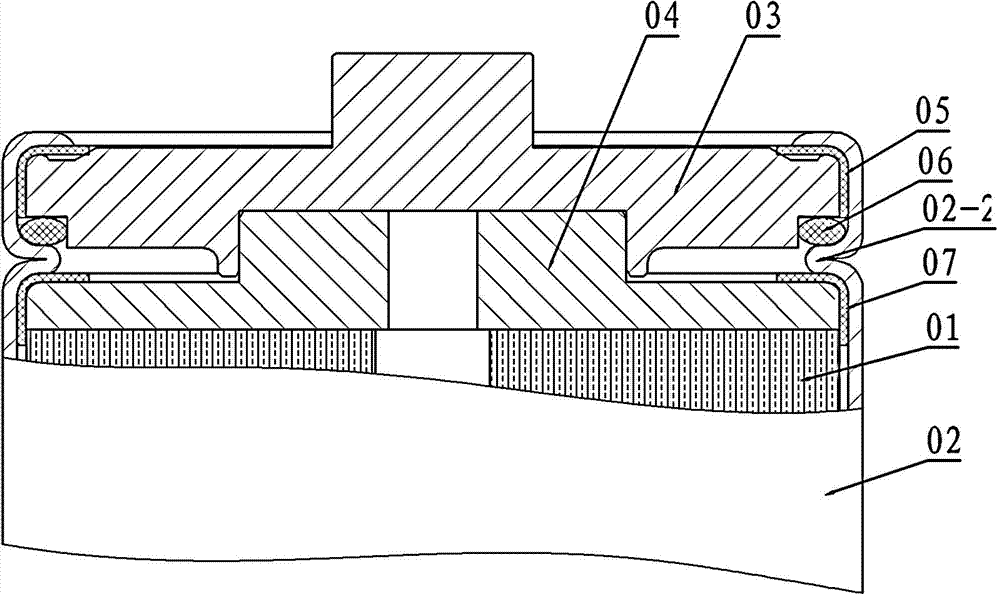

[0035] In step 3, an insulating sealing sleeve is sleeved on the outer periphery of the electrode lead-out structure, and the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com