Oxygen-enriched combustion pulverized coal boiler integrating chemical-looping high-temperature air separation oxygen production and CO2 gathering method

An integrated chemical and oxygen-enriched combustion technology, applied in the energy field, can solve the problems of large investment, low economic and energy utilization efficiency, and high energy consumption, and achieve the goals of improving heat utilization, reducing oxygen power consumption, and improving power generation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

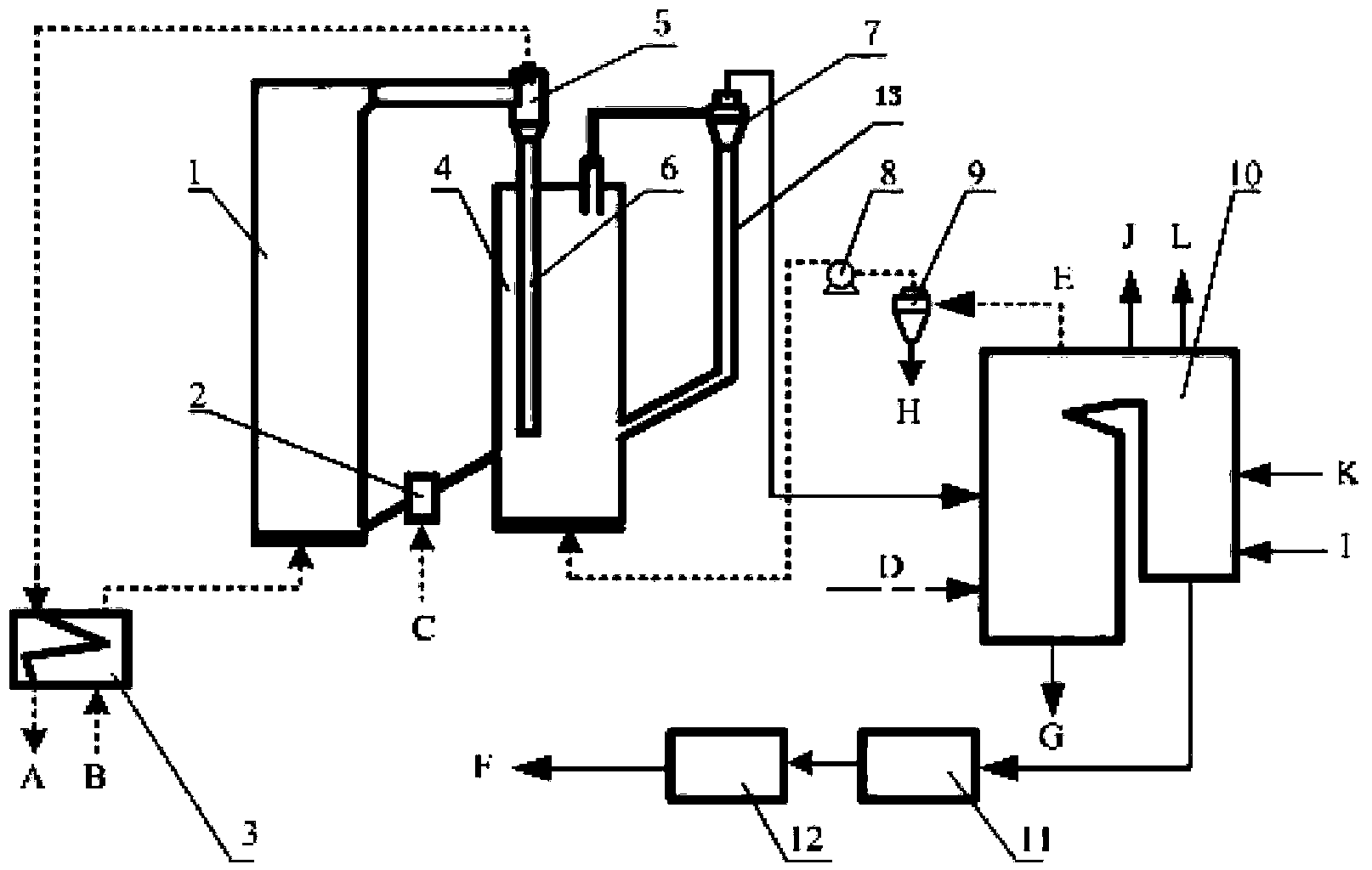

[0026] An oxygen-enriched pulverized coal boiler with integrated chemical chain high-temperature air separation for oxygen production, such as figure 1As shown, it includes an air preheater 3, an oxidation reactor 1, a first cyclone separator 5, an overflow tank 2 with a loose tuyere, a reduction reactor 4, a second cyclone separator 7, and a high-temperature flue gas induced draft fan 8 , high-temperature dust collector 9, coal-fired boiler 10, low-temperature dust collector 11, flue gas cooling compression purification device 12. The air preheater 3 is connected to the inlet of the lower end of the oxidation reactor 1, the lower end of the oxidation reactor 1 is connected to the reduction reactor 4 through the overflow tank 2 provided with a loose tuyere, and the outlet of the upper end of the oxidation reactor 1 is connected to the first cyclone separator 5 connected, the upper end outlet of the first cyclone separator 5 is connected with the air preheater 3, the feeding pi...

Embodiment 2

[0031] CO 2 A capture method comprising the steps of:

[0032] Step 1. The air B is heated by the air preheater 3 and then passed into the oxidation reactor 1, where it reacts with the low-valence oxygen carrier at 600-1300°C, and the low-valence oxygen carrier is oxidized into a corresponding high-valence state The air B becomes the high-temperature oxygen-poor air A, and the reaction product is separated by the first cyclone separator 5. The high-temperature oxygen-deficient air A enters the air preheater 3 to heat the air B, and discharges it into the atmosphere after cooling down. Oxygen enters the reduction reactor 4 from the feed pipe 6 of the first cyclone separator 5 . Oxygen carriers include manganese-based oxygen carriers, cobalt-based oxygen carriers, copper-based oxygen carriers or perovskite oxides. Manganese-based oxygen carrier is Mn 2 o 3 \Mn 3 o 4 , the cobalt-based oxygen carrier is Co 3 o 4 \CoO, the copper-based oxygen carrier is CuO\Cu 2 O, perovs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com