Improved UCT step-feed efficient biological denitrification and dephosphorization device based on DEAMOX technology and application method

A technology for staged water inflow and biological denitrification, which is applied in the fields of water pollutants, multi-stage water treatment, chemical instruments and methods, and can solve the problems of high carbon source, high energy consumption, dosing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

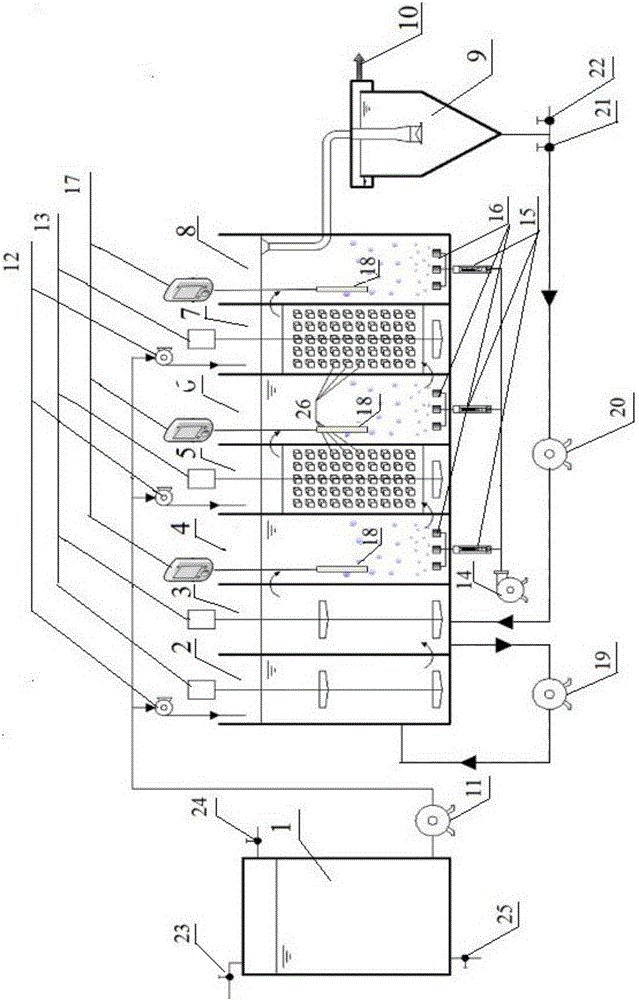

[0033] Specific Embodiment 1: This embodiment is based on the DEAMOX technology-based improved UCT staged influent high-efficiency biological denitrification and phosphorus removal device, including urban sewage raw water tank 1, anaerobic reactor 2, first stage anoxic reactor 3, and second stage connected in sequence. One-stage aerobic reactor 4, second-stage anoxic reactor 5, second-stage aerobic reactor 6, third-stage anoxic reactor 7, third-stage aerobic reactor 8, sedimentation tank 9 and outlet pipe 10, and return the sludge external return line from the bottom of the sedimentation tank 9 to the first section anoxic reactor 3 and return the sludge internal return line from the first section anoxic reactor 3 to the anaerobic reactor 2;

[0034] The anaerobic reactor 2, the first section anoxic reactor 3, the first section aerobic reactor 4, the second section anoxic reactor 5, the second section aerobic reactor 6, the third section anoxic Both the reactor 7 and the third ...

specific Embodiment approach 2

[0042] Specific implementation mode 2: This implementation mode is based on the application method of DEAMOX's improved UCT segmented water-influent high-efficiency biological nitrogen and phosphorus removal device, which is carried out in accordance with the following steps:

[0043] 1. Start-up phase - inoculation of activated sludge

[0044] Inoculate the activated sludge from the secondary sedimentation tank of the ordinary urban sewage treatment plant in the improved UCT subsection water inlet reactor. The rotameter 15 aerates the first-stage aerobic reactor 4, the second-stage aerobic reactor 6 and the third-stage aerobic reactor 8 to maintain the dissolved oxygen concentration DO=3~5mg / L, and open at the same time The agitator 13 of the anaerobic reactor 2, the first section anoxic reactor 3, the second section anoxic reactor 5 and the third section anoxic reactor 7 is mixed and vexed for several hours; when the mixed liquid ammonia nitrogen concentration NH 4 + When ...

specific Embodiment approach 3

[0057] Specific embodiment three: the difference between this embodiment and specific embodiment two is: in step one, inoculate the activated sludge of the secondary settling tank of the urban sewage plant in the improved UCT subsection water inlet reactor, so that the sludge concentration is 3500mg / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com