Catalytic gasification device, system and method

A technology of gasification furnace and carbon monoxide, which is applied in the direction of gasification process, gasification catalyst, granular/powdered fuel gasification, etc., and can solve the problems of high oxygen consumption, low methane content, poor safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

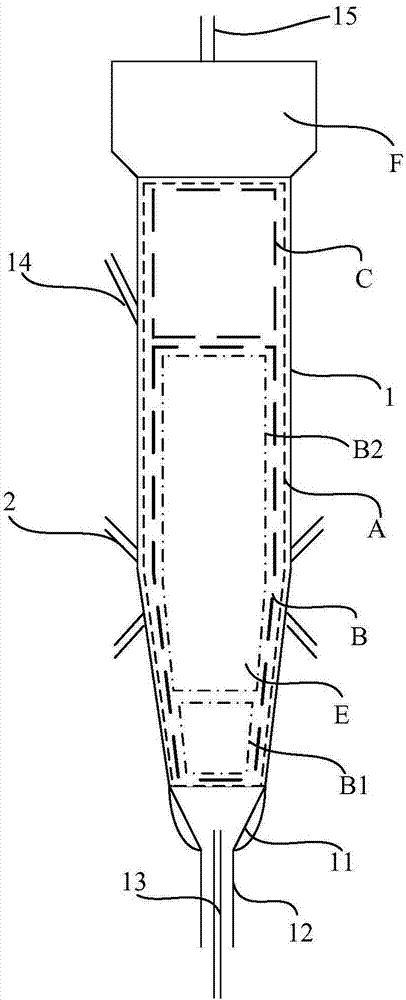

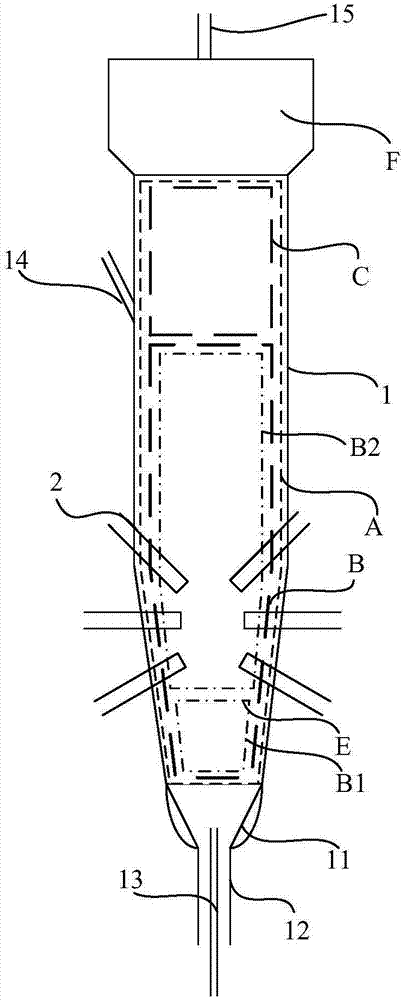

[0113] Divide the raw coal for coal catalytic gasification obtained above into at least three equal parts in such as Figure 8 The catalytic gasification of coal is carried out in the gasifier shown. The coal catalytic gasification process of each aliquot of coal catalytic gasification raw material coal is as follows:

[0114] see Figure 8 , the raw coal for coal catalytic gasification is transported into the gasifier 1 through the feed system 05, and at the same time, water vapor and oxygen are passed through the gas distribution plate 11 at the bottom of the gasifier 1, so that the water vapor and oxygen are mixed with the coal Coal catalytic gasification reaction occurs in the gasifier at 650-750℃ and 3-4.5MPa to generate crude gas rich in methane, carbon monoxide and hydrogen. The specific reaction process is as follows:

[0115] 2C+2H 2 O→2H 2 +2CO (1)

[0116] CO+H 2 O→CO 2 +H 2 (2)

[0117] 3H 2 +CO→CH 4 +3H 2 O (3)

[0118] 2C+O 2 →2CO (4)

[0119] C+O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com