Pilot-operated type control air channel system of breathing machine

A mechanical air circuit and pilot-operated technology, applied in the field of medical electronics, can solve the problems of short service life and high requirements for air supply control solenoid valves, and achieve the effects of improved service life, continuously adjustable oxygen concentration, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

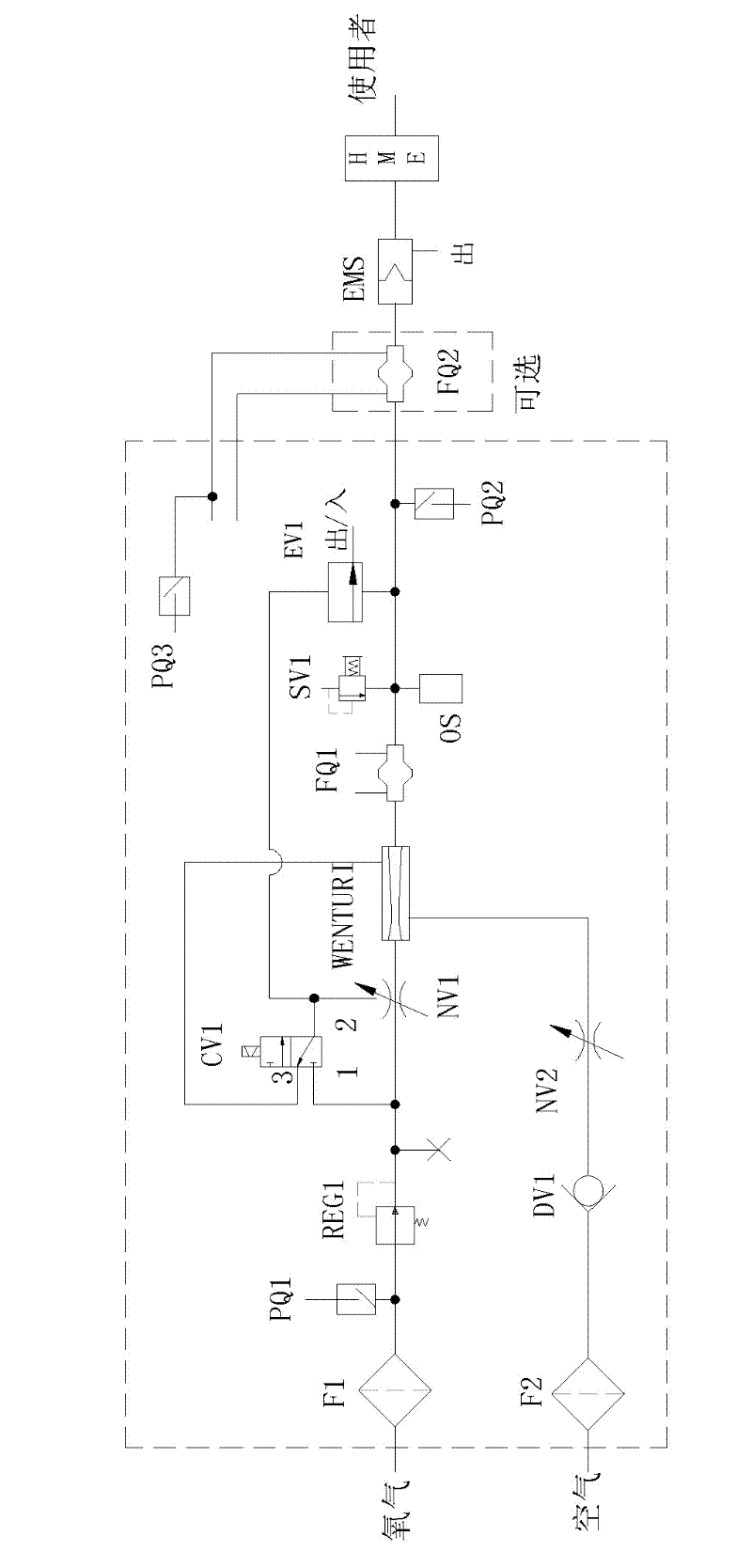

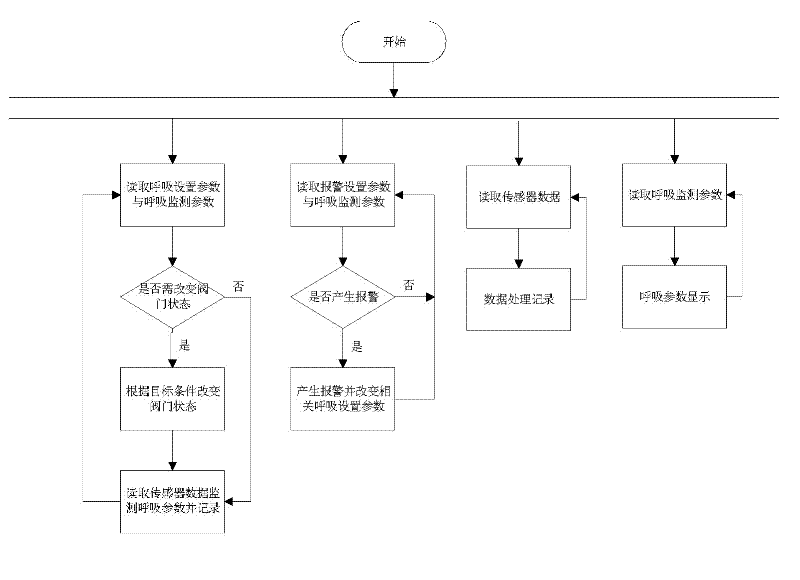

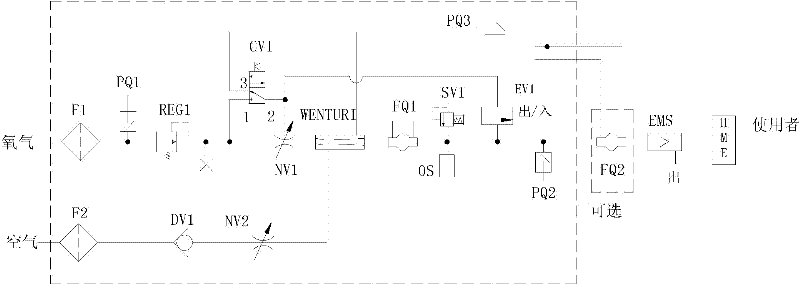

[0025] First, explain the key points of the gas path of the present invention:

[0026] (1) Venturi device and auxiliary pipeline structure, which can inhale air from the bypass, realize the mixing of air and oxygen, and reduce the oxygen concentration;

[0027] (2) The oxygen flow regulating valve NV1 controlled by the gas supply control solenoid valve CV1 adopts a non-serial structure, and the internal diameter of the gas supply control solenoid valve CV1 can be small.

[0028] Second, illustrate the structure of the gas circuit system of a specific embodiment of the present invention:

[0029] The air circuit system of the ventilator and the sensor thereon according to the specific embodiment of the present invention have a structure such as figure 1 As shown, it includes the main air path and its upper branch air path. The main air path includes two inlets and one outlet, which correspond to the oxygen communication pipe, the air communication pipe and the main pipe respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com