Modular oxygen generator with adjustable oxygen generation concentration and oxygen generation method

A modular, oxygen generator technology, applied in chemical instruments and methods, separation methods, oxygen preparation, etc., can solve the problems of lack of environmental protection, lack of intelligent management of oxygen generator equipment, inconvenient adjustment and operation, etc., to achieve the effect of easy performance expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

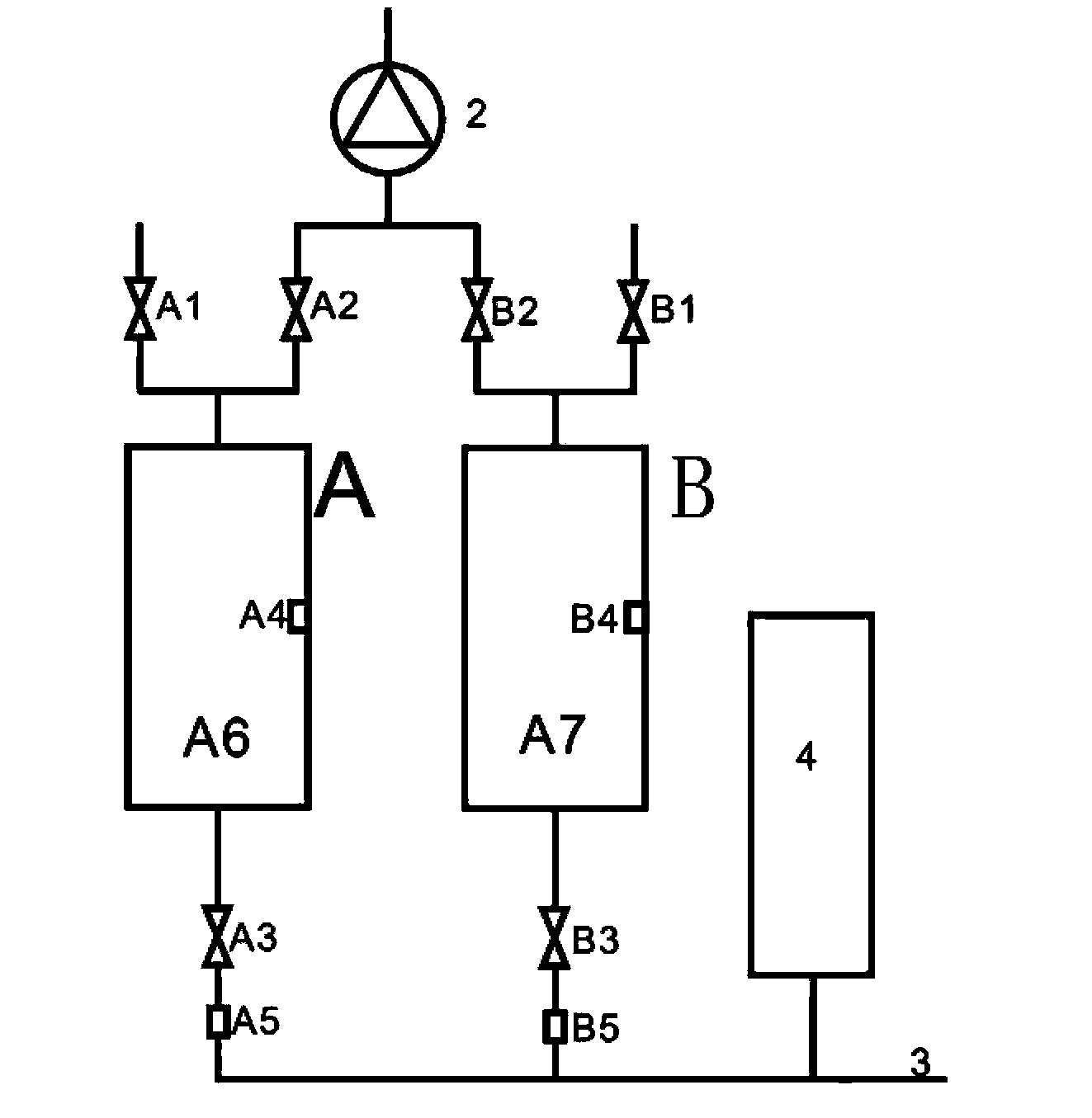

[0021] Referring to Fig. 1, the modularized oxygen generator with adjustable oxygen concentration of the present invention includes two groups of oxygen generator units A and B with the same structure, and a vacuum pump 2 connected to the two groups of oxygen generator units A and B simultaneously. , the gas outlet main pipe 3 connected to the two groups of oxygen generating units A and B at the same time, and the control circuit for controlling the working status of the two groups of oxygen generating units A and B.

[0022] Oxygen production unit A includes an adsorption tank A6, one end of the adsorption tank A6 is provided with an air intake pipe and an exhaust pipe, the air intake pipe and the exhaust pipe are respectively connected with an air intake valve A1 and an air extraction valve A2, and at the oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com