Method and device for burning low NOx by utilizing reburning of pulverized coal pyrolysis gas

A combustion method and pyrolysis gas technology, applied in combustion equipment, lighting and heating equipment, etc., can solve the problems of input-output ratio concerns, etc., and achieve the effects of reducing emissions, efficient reduction, and easy management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

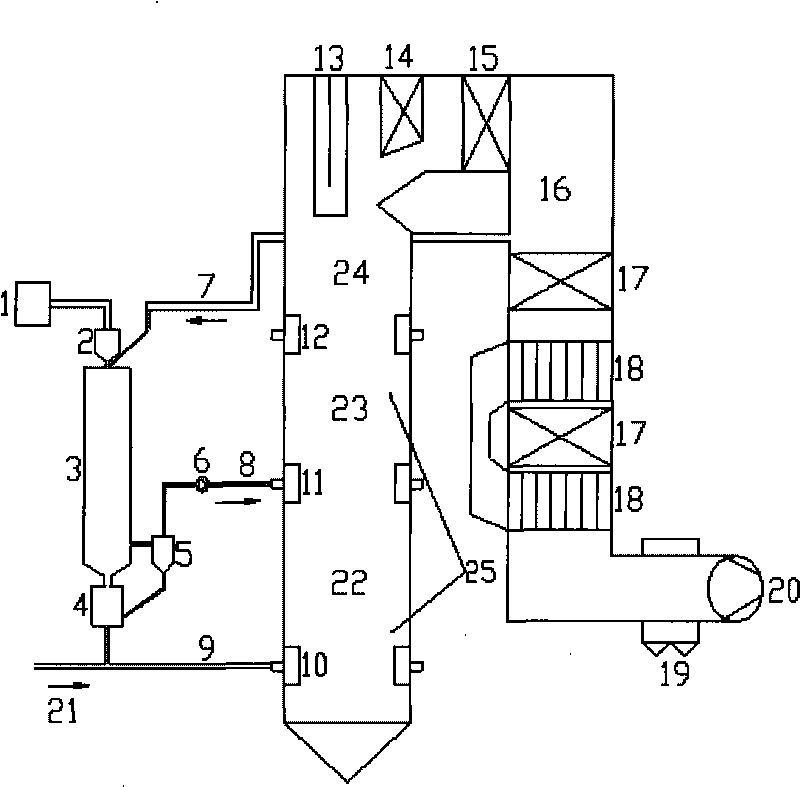

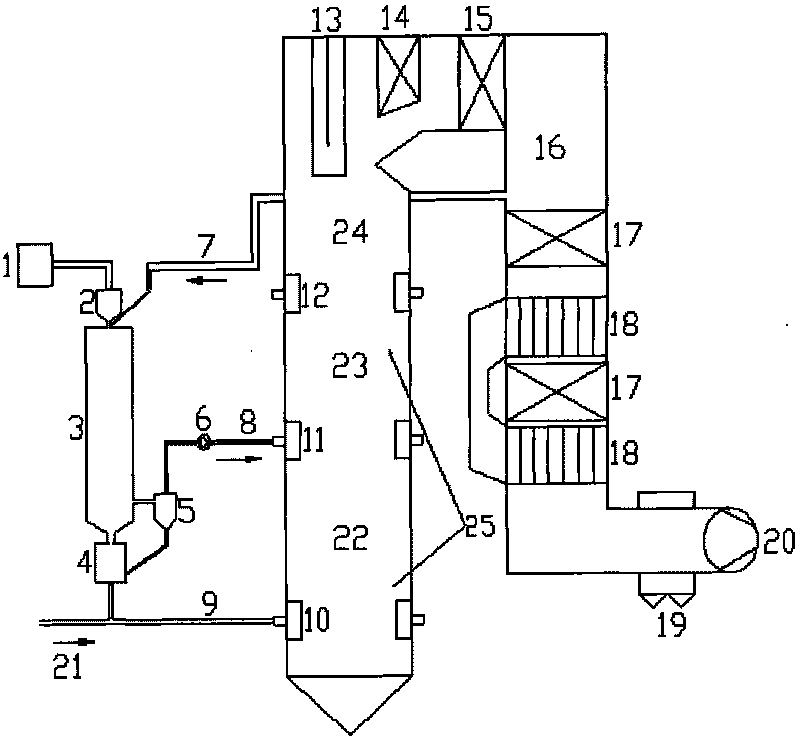

[0032] A low-NO x Apparatus for combustion method, see appendix figure 1 .

[0033] A low-NO x Combustion method device, including reheater 13, high temperature convection superheater 14, low temperature convection superheater 15, tail flue 16, economizer 17, air preheater 18, dust collector 19, induced draft fan 20, primary air duct 21. Pulverized coal fast pyrolysis device, flue gas circulation system and pulverized coal furnace with low NO x Combustion system and its connected pipelines;

[0034] The pulverized coal rapid pyrolysis device is composed of a pulverized coal bin 1, a coal hopper 2, a pyrolysis reactor 3, and a slag removal tank 4;

[0035] The flue gas recirculation system is composed of a cyclone separator 5, a fan 6 and a flue gas circulation pipe 7;

[0036] Pulverized coal boiler low NO x The combustion system is composed of pulverized coal nozzle 10, pyrolysis gas nozzle 11, air nozzle 12 and pulverized coal boiler furnace 25;

[0037] Pulverized co...

Embodiment 2

[0041] A low-NO x burning method

[0042] About 25% of the pulverized coal boiler flue gas is drawn by the fan 6, circulates back from the tail flue 16, passes through the flue gas circulation pipe 7, and flows in parallel with the pulverized coal sent from the coal bunker 1 through the sealed gravity feeding coal hopper 2 into the fast The pyrolysis reaction is carried out in the pyrolysis reactor 3 . The flue gas temperature at 16 at the tail flue is about 600°C; the pulverized coal entering the fast pyrolysis reactor accounts for about 30% of the total powder feed to the pulverized coal boiler, and the pyrolysis reaction temperature is controlled at about 500°C, and the reaction time is about 5S .

[0043] Heated by circulating hot flue gas, the pyrolysis gas produced by the rapid pyrolysis of coal powder comes out from the side of the lower part of the pyrolysis reactor 3, and enters the coal powder through the cyclone separator 5, the induced draft fan 6, and the pulver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com