Pulverized coal burner

A technology of pulverized coal burner and powder feeding pipe, which is applied in the direction of burner, burner for burning powder fuel, combustion method, etc. It can solve the problems that small and medium-sized industrial pulverized coal boilers cannot be directly used, and achieve low operating costs and high combustion efficiency. The effect of fully and prolonging the burning length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

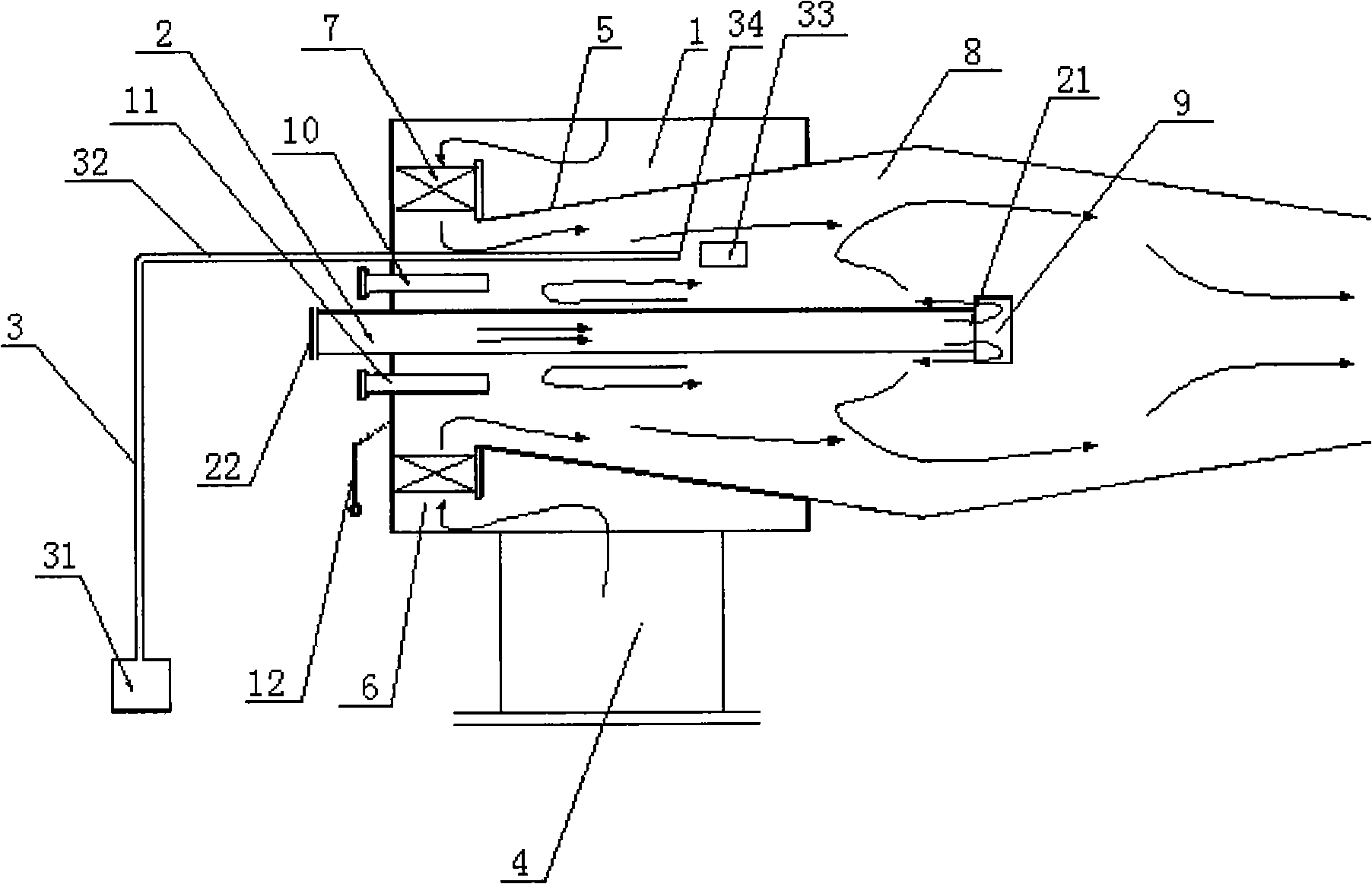

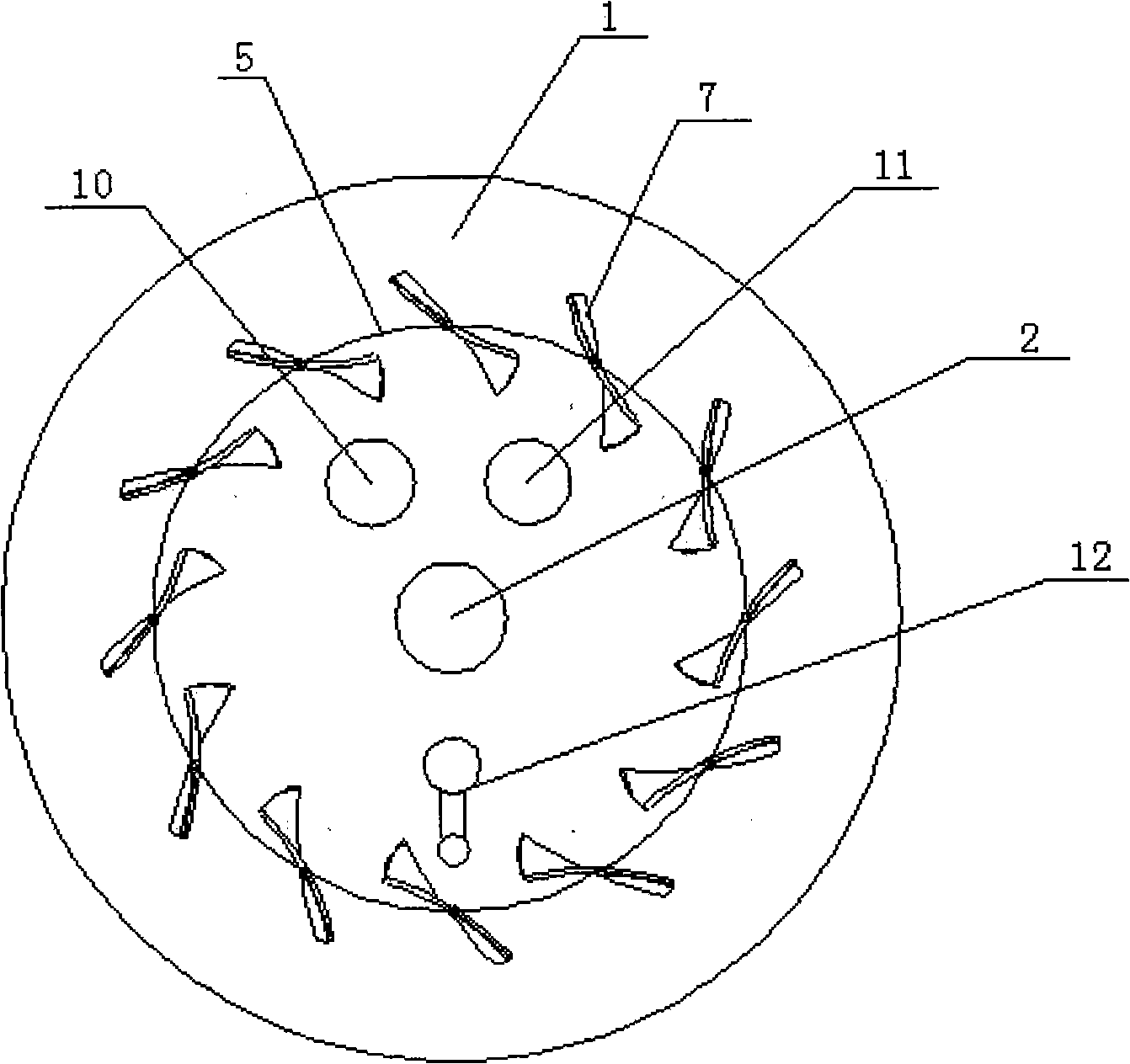

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0013] Such as figure 1 As shown, the present invention includes a bellows 1, a powder feeding pipe 2, an ignition device 3 and a blowing pipe 4. A cylindrical fixed baffle 5 with a conical cross-section is arranged axially inside the bellows 1, and an annular gap 6 is left between one end of the fixed baffle 5 and the bellows 1, and a plurality of swirl blades 7 are arranged in the circumferential direction of the annular gap 6. There is a pre-chamber 8 inside the fixed baffle 5 .

[0014] The outlet end 21 of the powder feeding pipe 2 runs through the center of the air box 1 and enters the pre-combustion chamber 8, the inlet end 22 is arranged outside the air box 1, and the powder feeding pipe 2 and the air box 1 are fixedly connected. A backflow cap 9 is disposed at the end of the outlet end 21 , and a certain gap remains between the backflow cap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com