Explosion-proof processing method of medium-storage type bituminous coal boiler and special system thereof

A treatment method and boiler technology, applied in combustion methods, hearth furnaces, furnaces, etc., can solve problems such as personal casualties, troubles for the safe operation of power plants, and large hazards, and achieve great safety significance, prevent personal injury accidents and major equipment damage, significant social benefits

Active Publication Date: 2009-02-04

NORTHEAST POWER SCI RES INSTITUTION +2

View PDF0 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, there has always been a hidden danger of explosion in the intermediate storage pulverizing system, which has become a technical problem that has plagued the safe operation of power plants for a long time

Due to the characteri

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

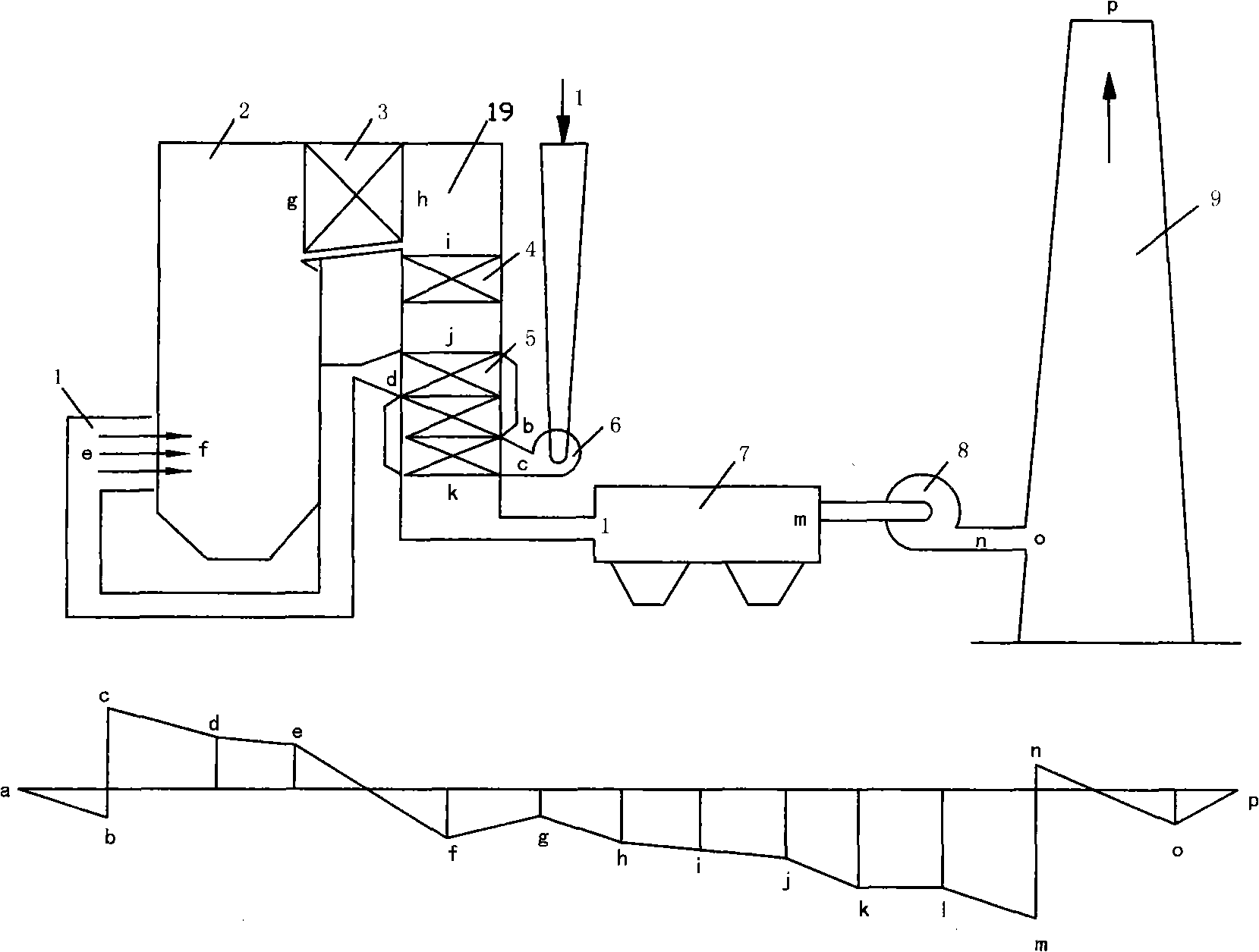

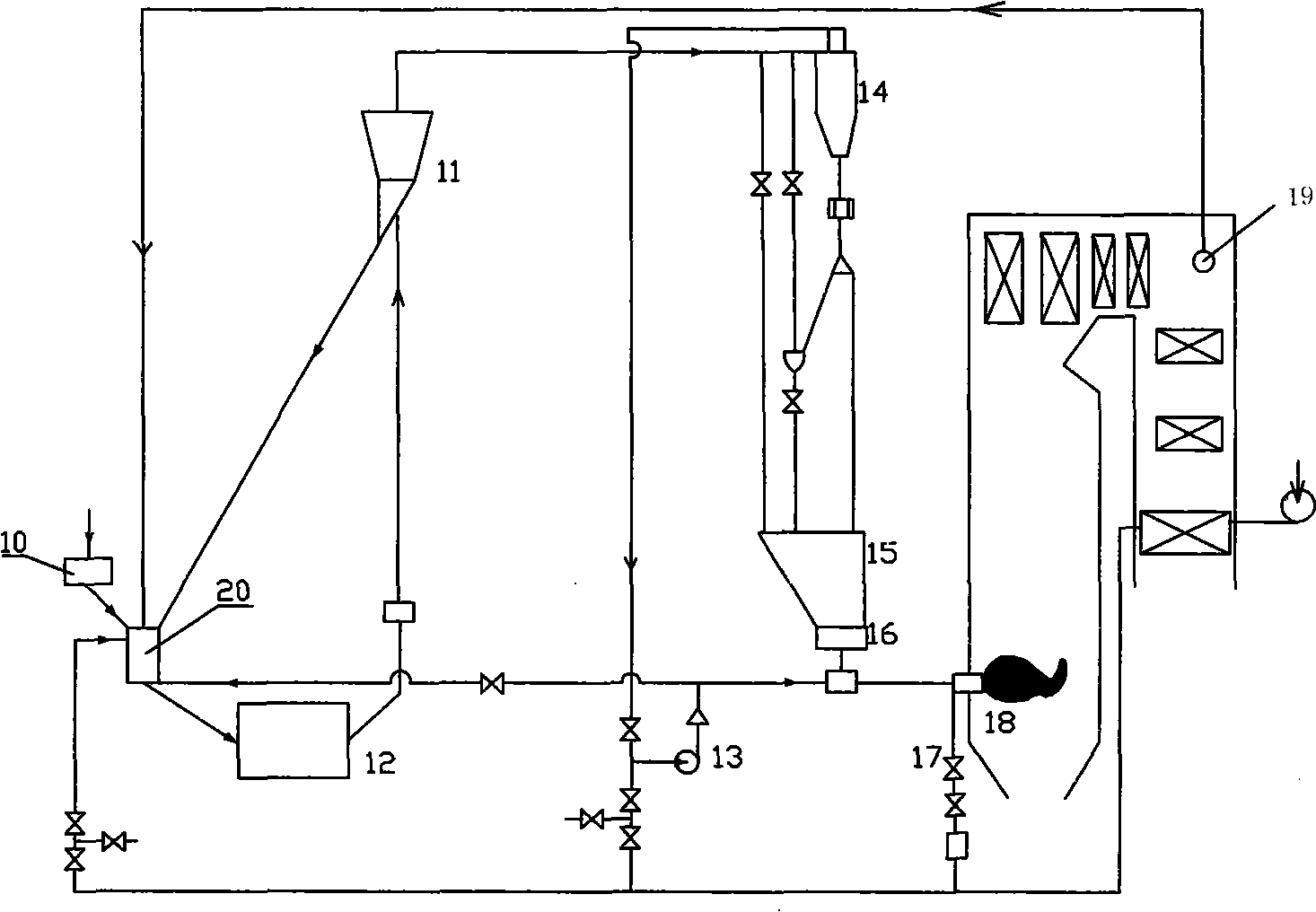

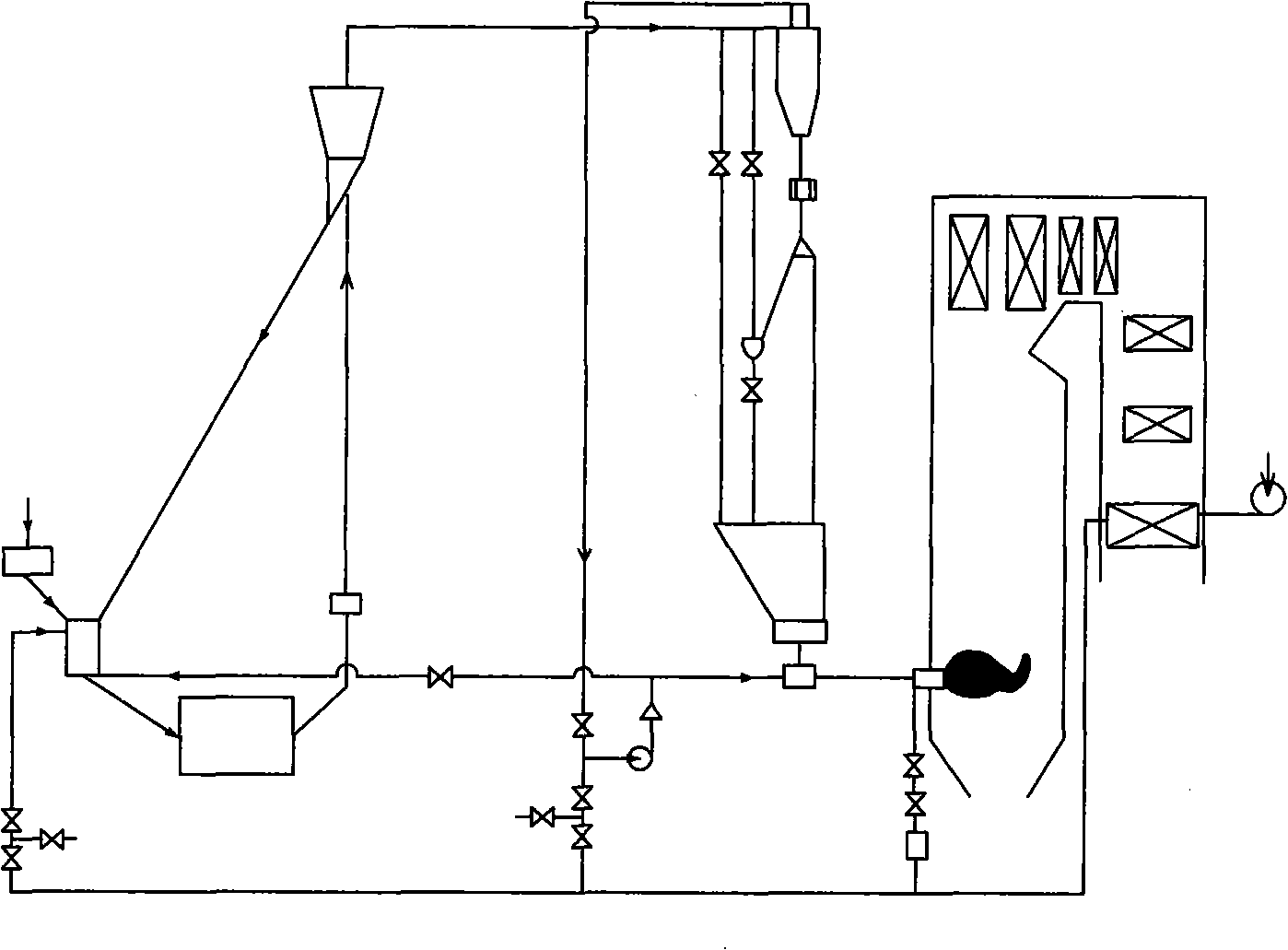

The present invention belongs to the security technical field of the power generation, in particular relates to an anti-explosion processing method and a special system that is applied on a mid-reserved coal powder boiler that combusts the wood coal, and is characterized in that smoke is taken at a flue direction-changing chamber that is arranged at the tail part of the coal boiler; the smoke is mid-temperature boiler smoke at 400 to 600 DEG C with oxygen content being lower than 16 percent at volume; the mid-temperature boiler smoke is conveyed to an inlet of a coal grinding machine in the gas coal boiler powder production system through a pipeline, so that the oxygen content in the powder production system is reduced by the mid-temperature boiler smoke, and the mid-temperature boiler smoke is adopted as the drying gas to dry the coal powder. The present invention aims at resolving the problems that how the mid-reserved gas coal boiler effectively prevents the explosion.

Description

1. Technical field: [0001] The invention belongs to the technical field of power generation safety, and in particular relates to an anti-explosion treatment method and a special system for an intermediate-storage pulverized coal boiler mixed with lignite. 2. Background technology: [0002] Among the nearly 60,000MW thermal power capacity in Northeast China, 76% are bituminous coal boilers, and 70% of the bituminous coal boilers use intermediate storage bin-type pulverizing systems. The volatile content of bituminous coal in Northeast China is relatively high. Therefore, the explosion protection of pulverizing system has always been a technical problem that plagues the safe operation of power plants. In recent years, due to the gradual depletion of bituminous coal resources and the rapid increase in coal consumption in Northeast China, some units have to blend the abundant and relatively low-priced lignite. Since lignite has a higher volatile content than bituminous coal and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23K1/00F26B3/06

Inventor 吴景兴邹天舒冷杰张永兴王文生蒋翀徐宪斌梁明文苏东刘学增吴炬袁德权李彦龙宋大勇高吉录

Owner NORTHEAST POWER SCI RES INSTITUTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com