An explosion-proof method for an electric welding machine

A technology of electric welding machine and welding torch, which is applied in arc welding equipment, welding equipment, welding accessories, etc. It can solve problems such as maintenance difficulties, economic losses, threats to miners' life safety, etc., and achieve the effect of solving explosion-proof problems and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

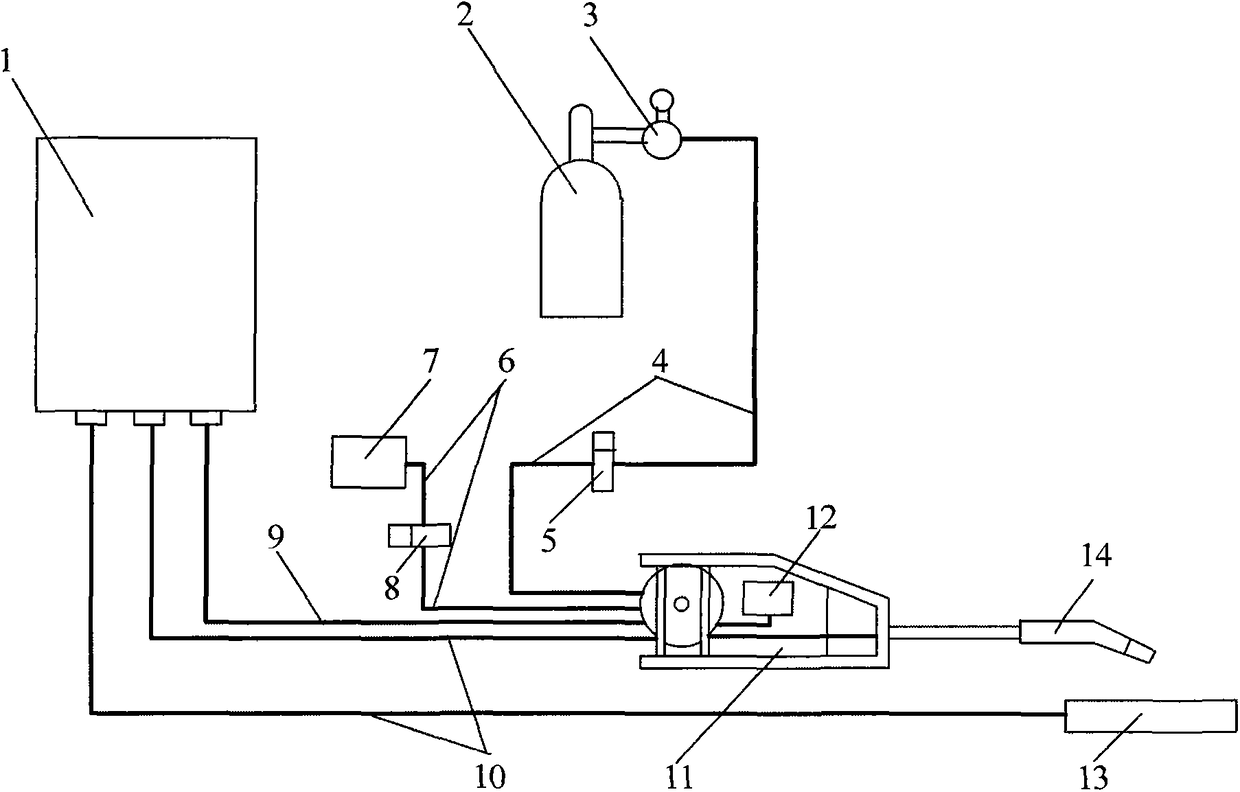

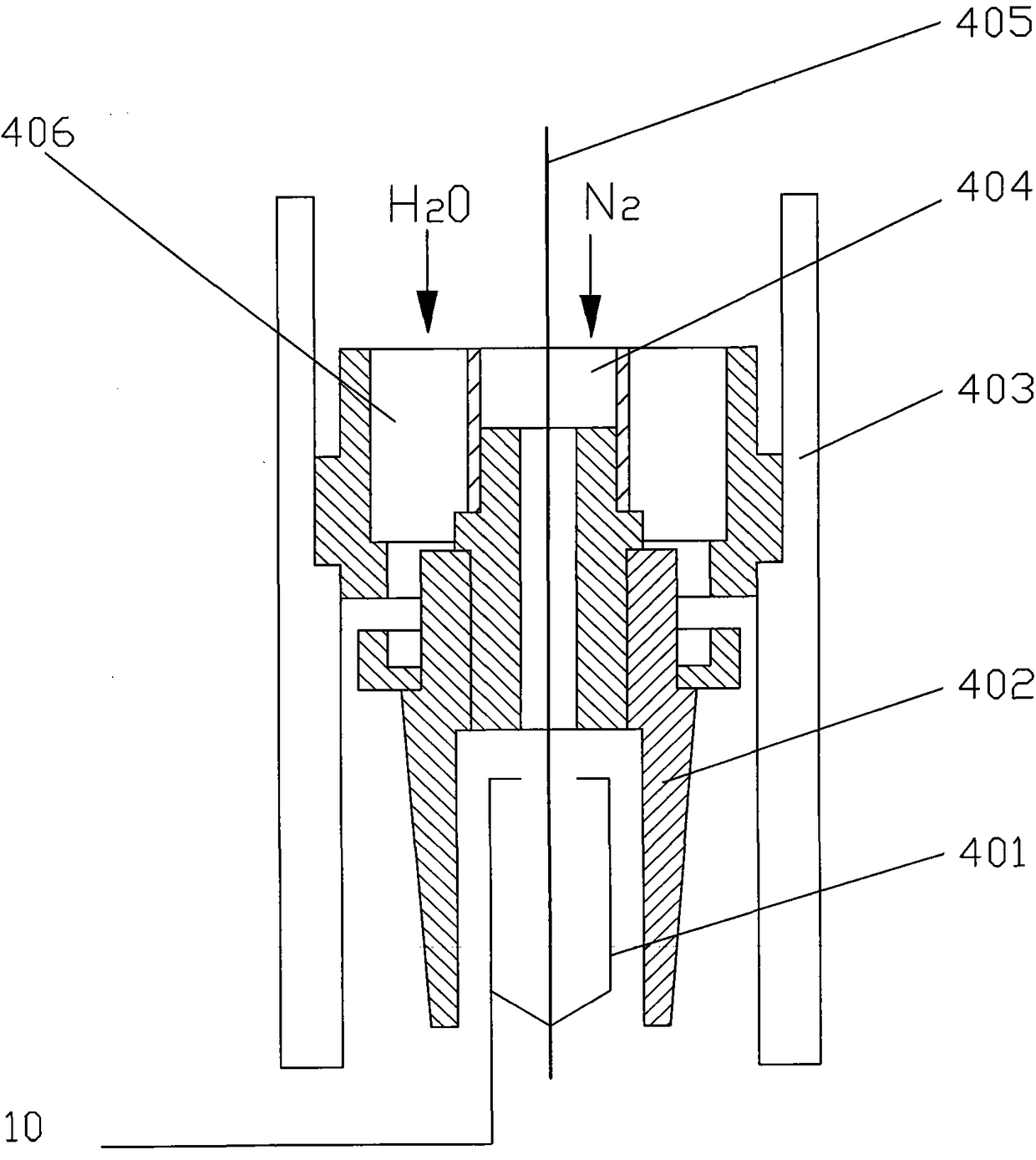

[0013] Example: figure 1 It is the overall structural system diagram of the present invention, adopting N 2 The gas is supplied to the welding torch by the flameproof welding power source 1, N 2 Gas cylinder 2, pressure reducing valve 3, gas supply hose 4, gas flow sensor 5, water pipe 6, water pump 7, water flow sensor 8, control cable 9, welding cable 10, wire feeder 11, gas sensor 12, workpiece 13, Welding torch 14 is formed. Supply N to the welding torch 14 through the gas supply hose 4 and the gas flow sensor 5 2 At the same time, the high-pressure water of the water pump 7 supplies high-pressure water to the welding torch 14 through the water pipe 6 and the water flow sensor 8. The flameproof welding power supply 1 outputs electric energy to the workpiece 13 and the welding torch 14 through the cable 10, and the gas flow sensor 5 is connected to the gas flow sensor 5 through the control cable 9. The control signals of the water flow sensor 8 and the gas sensor 12 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com