Minitype explosion-proof speed reducing motor

A technology of miniature geared motors and geared motors, applied in electrical components, electromechanical devices, electric components, etc., to solve the explosion-proof problem and ensure reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with the embodiment in the accompanying drawings the present invention is further described:

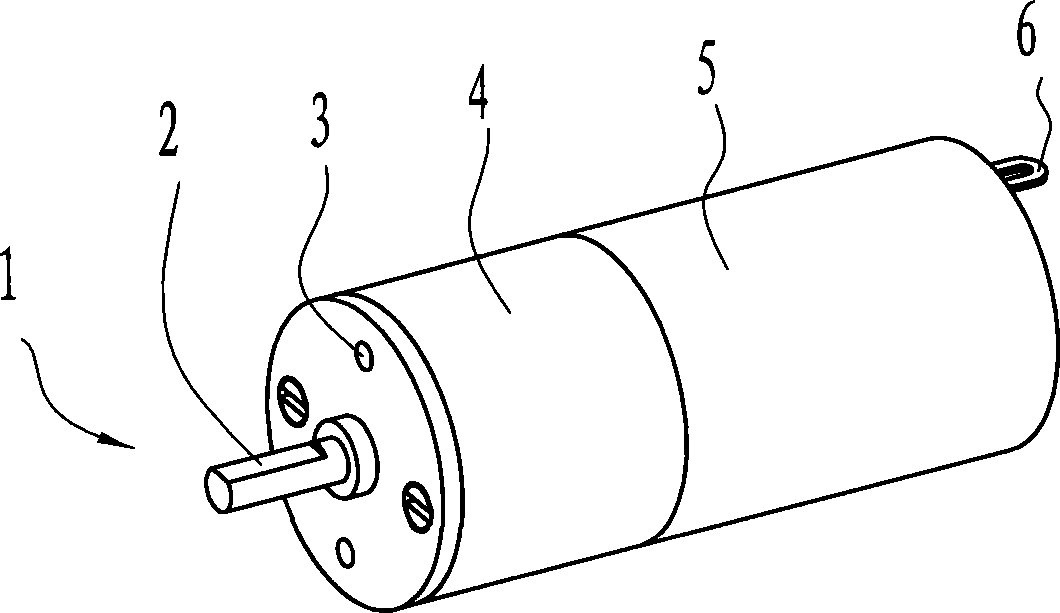

[0013] figure 1 It is a three-dimensional structure diagram of a miniature geared motor in the prior art, including a reducer 4 and a motor 5, the rear end of the motor part 5 is provided with a terminal 6, the front end of the reducer part 4 is provided with a fixed screw hole 3, and the motor shaft 2 protrudes from the front end of the reducer part 4, and the ordinary miniature geared motor 1 does not have flameproof performance.

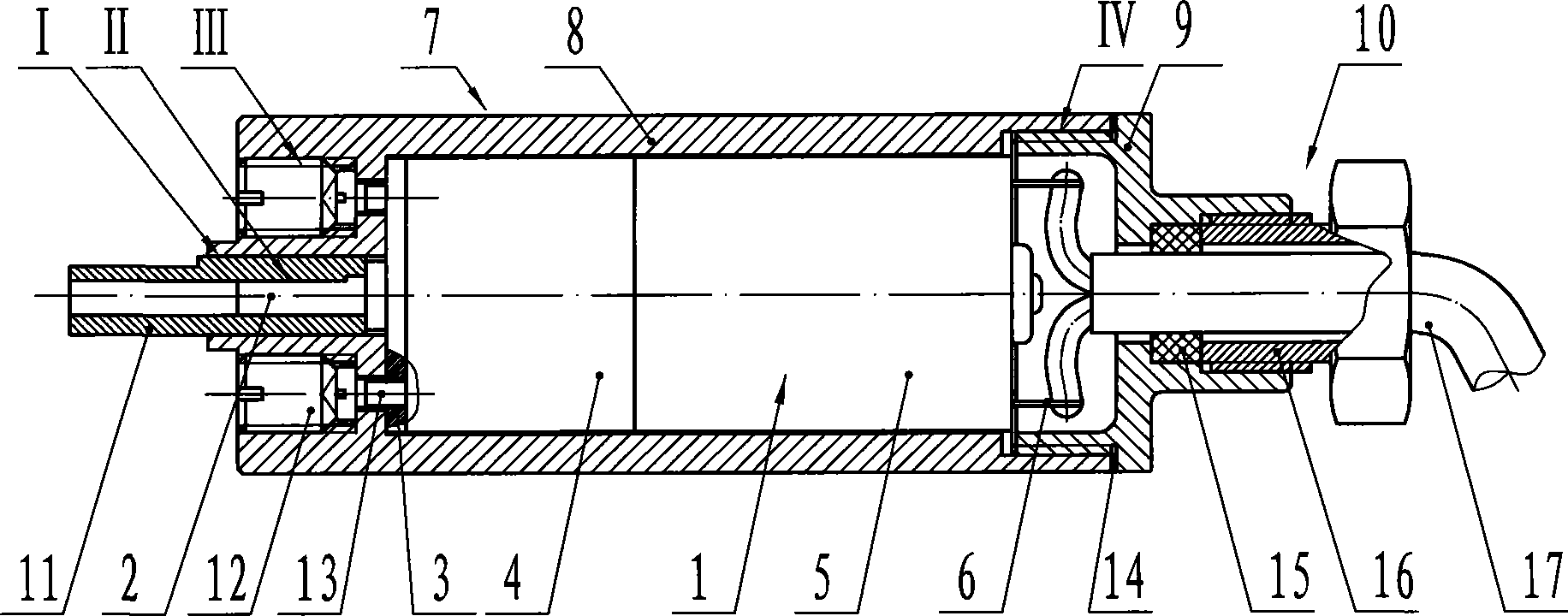

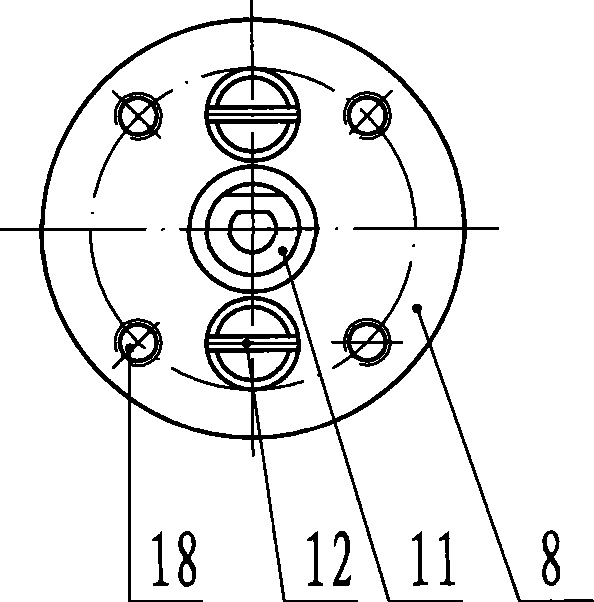

[0014] figure 2 It is the structural diagram of the miniature explosion-proof geared motor of the present invention, which is figure 1 The structural diagram of the embodiment in which the miniature geared motor shown in is transformed into a miniature flameproof geared motor. A flameproof enclosure 7 is provided outside the miniature geared motor 1. The flameproof enclosure 7 is composed of a flameproof cylinder 8 and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com