Pretreatment method for extracting plant effective components

A plant active ingredient and pretreatment technology, applied to medical preparations containing active ingredients, plant/algae/fungus/moss ingredients, plant raw materials, etc., can solve high energy consumption costs, organic solvent solvent explosion, plant cell wall rupture and other problems, to achieve the effect of short processing time, large processing capacity and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Extraction of Ganoderma lucidum polysaccharide.

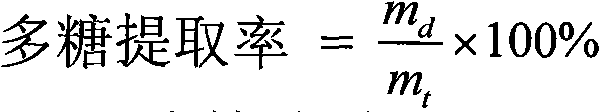

[0021] Grind the dried Ganoderma lucidum into 20-50 meshes, weigh 100g with an electronic balance, infiltrate water with a weight of 500g, stir well, infiltrate for 1 hour, vacuum microwave radiation for 7 minutes, and the power density of the microwave is 2.5-3.0 watts / gram (w / g), vacuum degree 75Kpa; Ganoderma lucidum after vacuum microwave irradiation immediately enters a single-screw extruder, and the compression ratio of the screw is 1:3; subsequent extraction is performed by Soxhlet method, heated and refluxed at 80°C for 2.5 hours (h), Ganoderma lucidum polysaccharide The extraction yield is 1.753%.

[0022] The present invention adds follow-up existing Soxhlet method to extract and the comparison of using existing Soxhlet method to extract separately and result is shown in Table 1 (the raw material is identical, experiment repeats 3 times and gets mean value), as can be seen from the data in Table ...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com