On-line adjustable coal flow distributing device

a distribution device and adjustable technology, applied in lighting and heating equipment, combustion process, lump/pulverized fuel feeder/distribution, etc., can solve the problems of increasing the pressure drop of the coal pipe, difficult to achieve uniform coal flow distribution to the coal pipes, and increasing the difficulty of coal flow distribution to the burners. achieve the effect of reducing the pressure drop of the system, reducing the difficulty of coal flow distribution, and efficient controlling the balance of multiple coal flows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

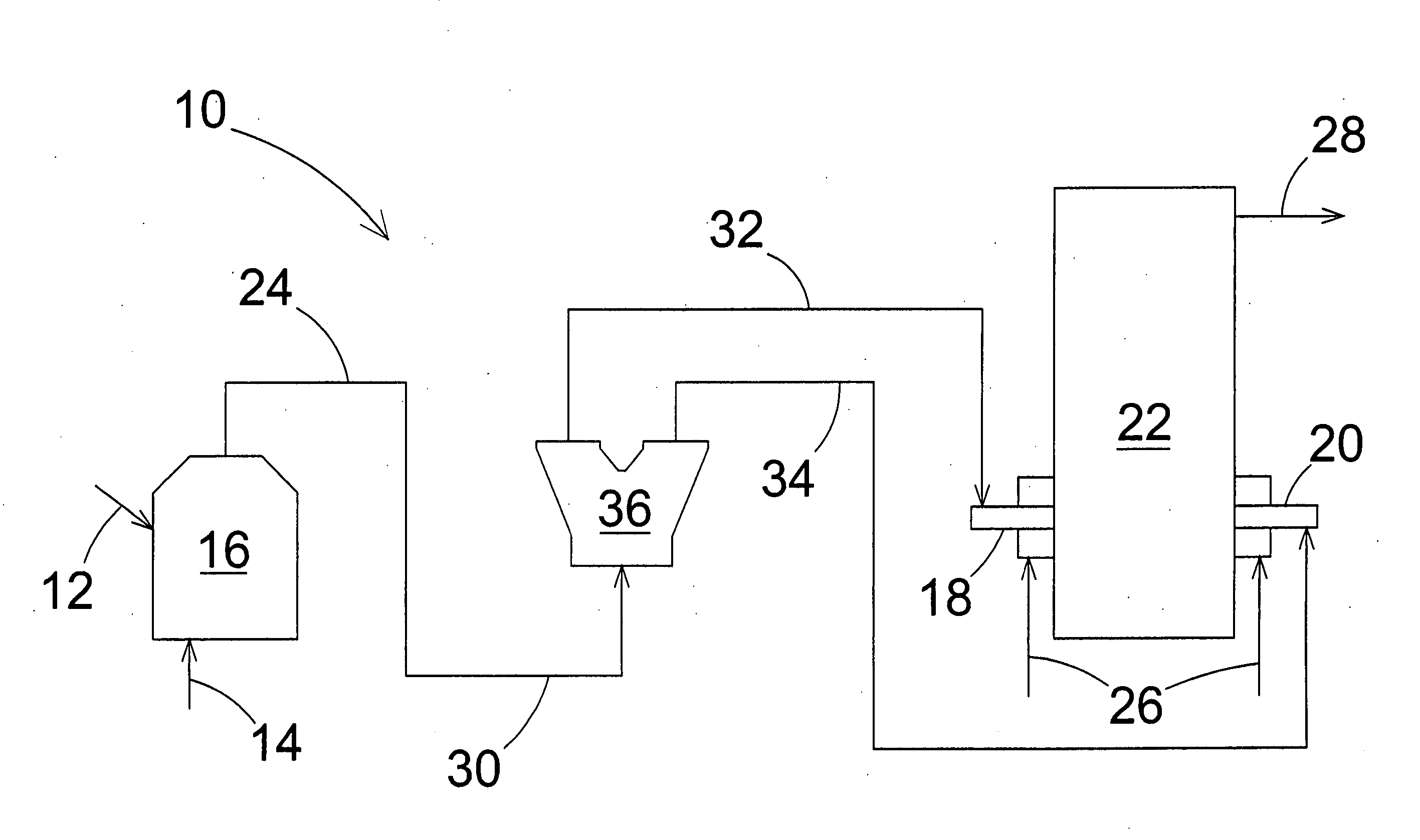

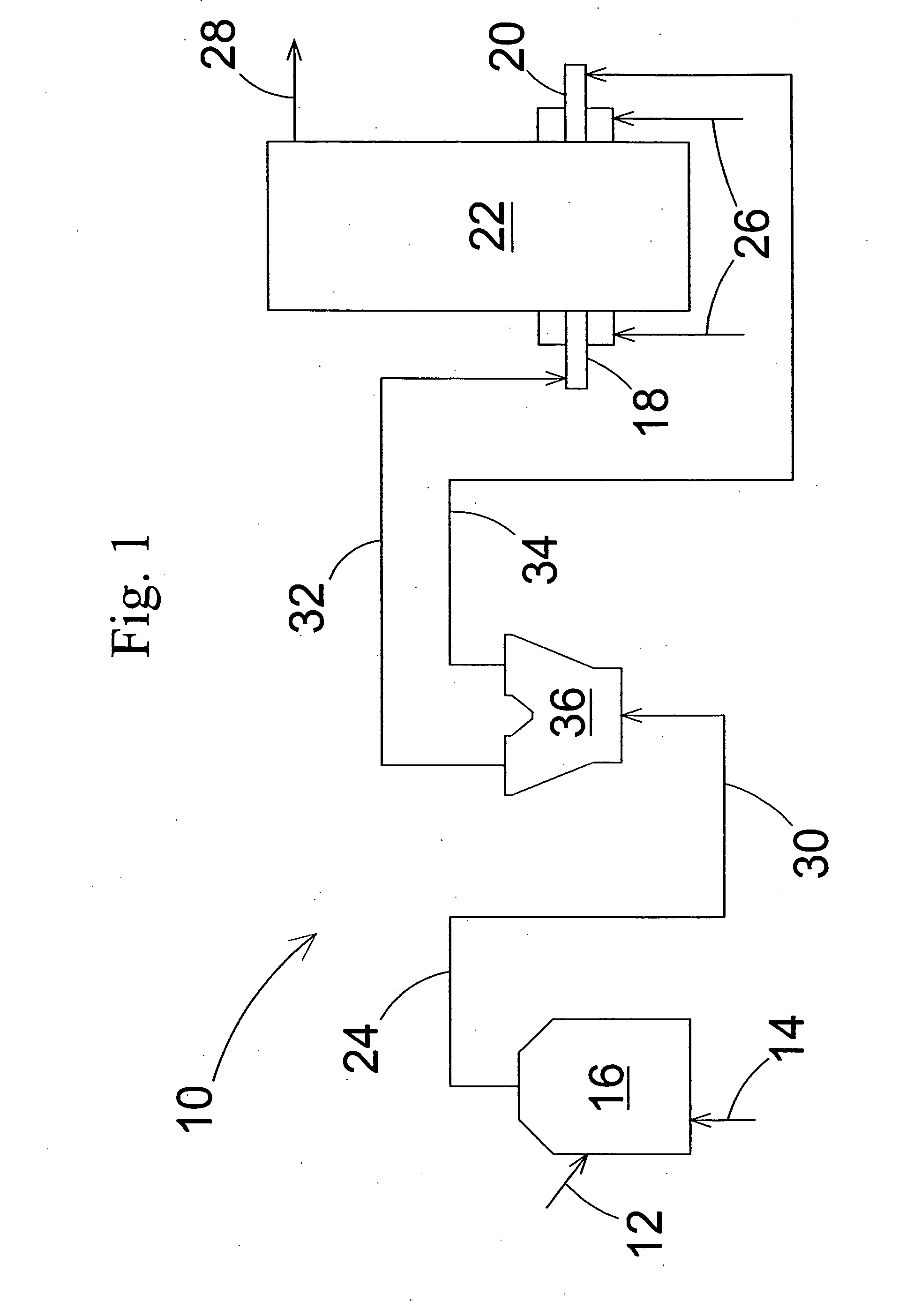

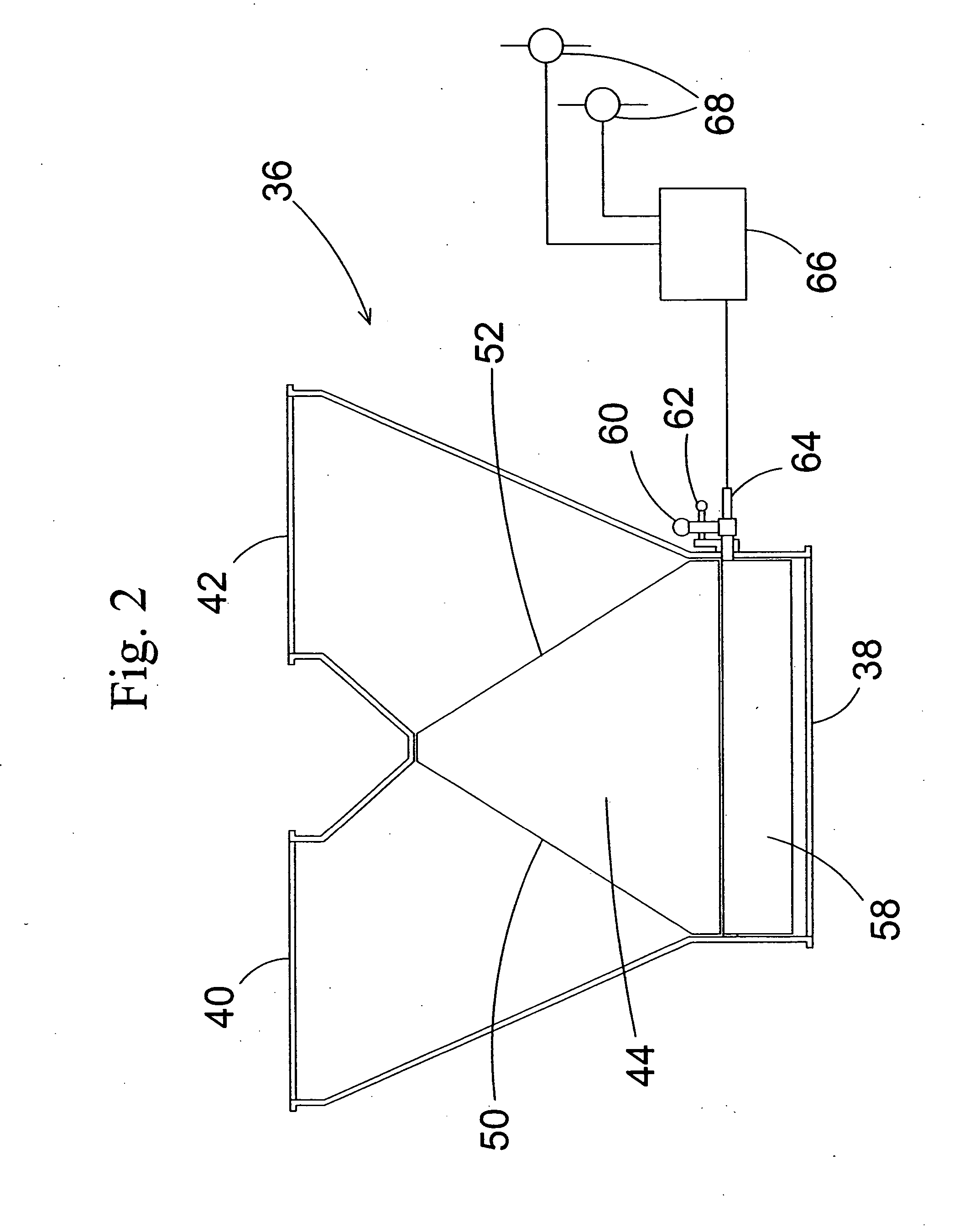

[0025] Referring now in greater detail to the drawings, FIG. 1 schematically shows an overall view of a pulverized coal-fired boiler system 10. Coal 12 and air 14 are introduced into a pulverizer 16 in which the coal is pulverized into a size suitable for combustion in each of two burners 18, 20 disposed on the sidewalls of a boiler 22. In other types of boilers, the burners 18, 20 can be disposed on the corners, roof, and / or arches of the boiler. Pulverized coal and primary air are conveyed along a coal feed system 24 from the pulverizer 16 to the burners 18, 20, where the coal is combusted by primary air and secondary air 26. Exhaust gases produced in the combustion process are discharged from the boiler through a discharge gas channel 28.

[0026] The coal feed system 24 comprises, in the simple pulverized coal firing boiler system shown in FIG. 1, an upstream pipe 30, connected to the pulverizer 16, and two downstream pipes 32 and 34, connected to the burners 16 and 18, respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com