Method for monitoring wall temperature of heating surface and thickness of scale cinder of boiler superheater or reheater

A superheater and reheater technology, which is applied in the direction of boiler working status indication, etc., can solve problems such as misjudgment, inability to train, and inability to monitor

Active Publication Date: 2014-03-26

ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

View PDF7 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Therefore, the leakage problem of boiler heating surface burst tubes has always been the main reason for the forced shutdown of thermal power units at home and abroad.

It has a good effect on monitoring the overtemperature caused by blockage, but it cannot monitor the local overtemperature caused by local thermal deviation because the monitoring point is far away from the overtemperature point, and when scale or scale appears, the heat transfer is weakened , so the outlet steam temperature has dropped, which is opposite to the direction of the wall temperature change, so the traditional monitoring method cannot reflect or even cause misjudgment

The pure neural network method cannot be trained because the scale thickness cannot be known during operation, and the simple furnace inner wall temperature method is difficult to implement and the cost is too high for long-term continuous operation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0159] For a 600MW supercritical pressure boiler, the calculation process for wall temperature monitoring is shown in the table.

[0160]

[0161]

[0162]

[0163]

[0164]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

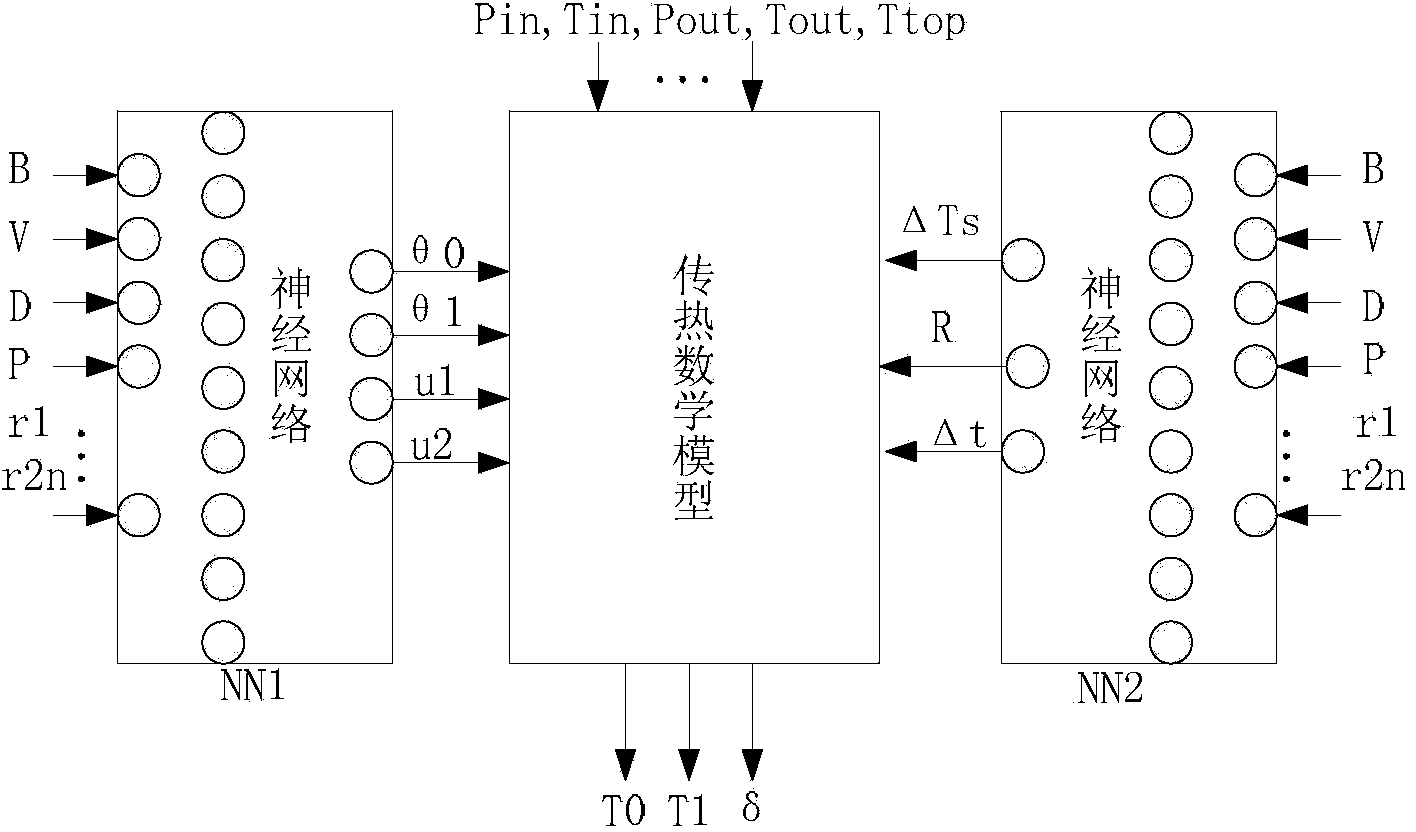

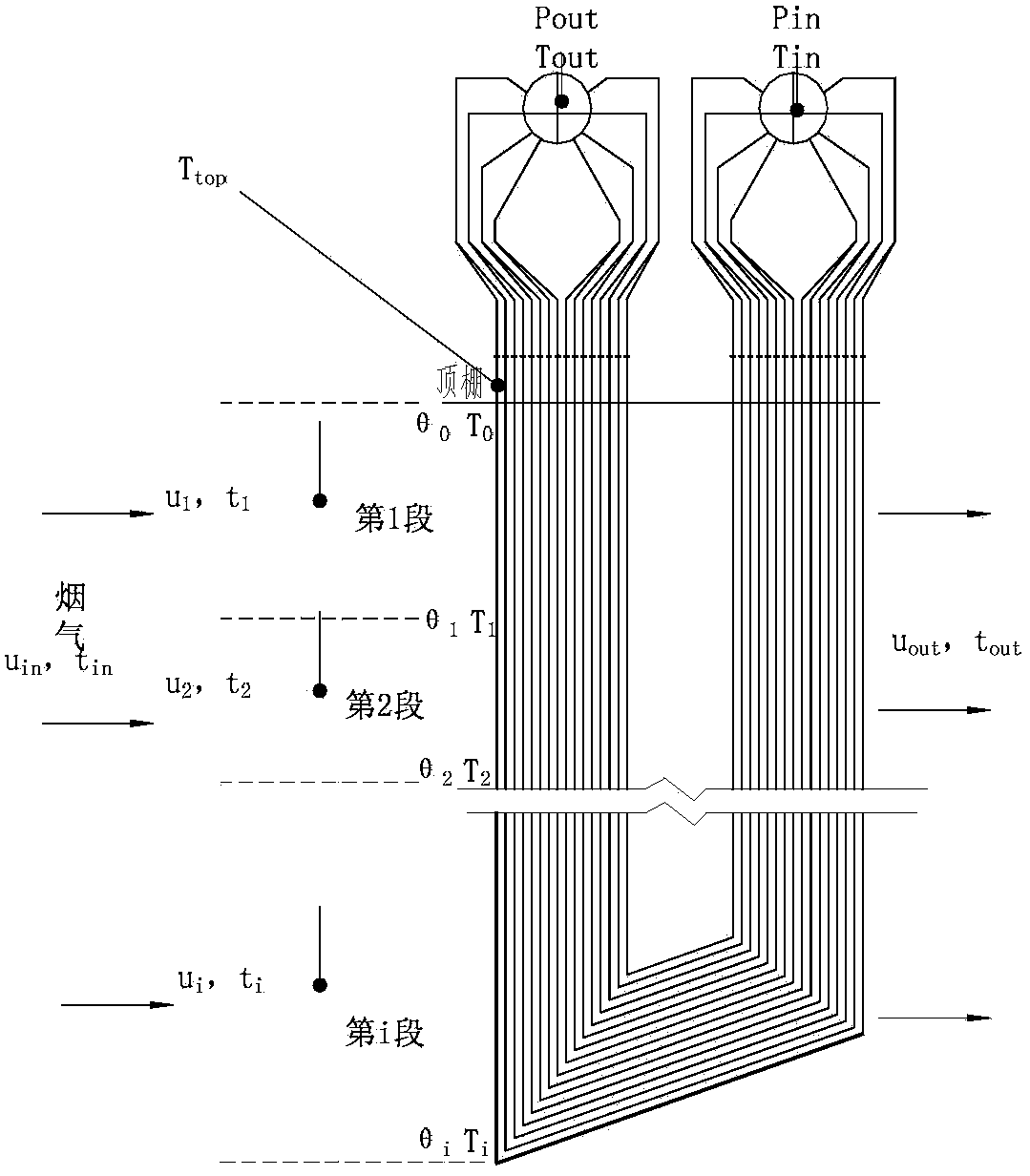

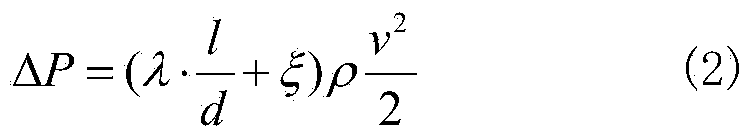

The invention discloses a method for quantitatively and online monitoring the metal wall temperature of a heating surface and the thickness of a scale cinder (scale layer) of a boiler superheater or a reheater. The method includes the steps that according to operating parameters of a boiler, flue-gas temperature and speed of partition sections in the front of a pipe are predicted and monitored through a neutral network, and based on the flue-gas temperature and the speed, the distribution of the wall temperature of the heating surface and the thickness of the scale cinder (scale layer) of the superheater or the reheater are acquired according to a heat transfer mathematical model of the heating surface. The method has the advantages that the method is simple, rapid and capable of being continuously conducted, regular automatic learning can be achieved, the method can be used for quantitatively monitoring the wall temperature of the heating surface and the thickness of the scale cinder in the actual operating process of the pulverized coal boiler, and a quantitative basis is provided for preventing pipe explosion through optimizing, adjusting and controlling thermal deviation and for managing the service life of the heating surface of the boiler.

Description

technical field [0001] The invention relates to an on-line monitoring method for the wall temperature of the heating surface of a boiler superheater and a reheater and the thickness of an oxide scale (scale layer). Background technique [0002] Boiler superheaters, reheaters and other components are subjected to high pressure, high temperature, and high humidity, and have been exposed to very harsh environmental media such as high-temperature steam and high-temperature flue gas for a long time. During service, creep, fatigue, steam oxidation, Complex processes such as coal ash corrosion lead to material aging and failure. Therefore, the leakage problem of boiler heating surface burst tube has always been the main reason for the forced shutdown of thermal power units at home and abroad. However, the parameters of the working medium in the superheater and reheater of the ultra-supercritical unit are significantly higher than those of the critical unit, and the working conditi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F22B37/38

Inventor 王伟钟万里汪淑奇陈冬林邓平

Owner ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com