Air-water combined cooling dry slagging method and system of pulverized coal boiler

A pulverized coal boiler and combined cooling technology is applied in the field of slag cooling of pulverized coal boilers, which can solve the problems of unavailability of slag waste heat, waste of energy loss, and large operation water consumption, so as to reduce incomplete combustion losses, reduce coal consumption, and improve boilers. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

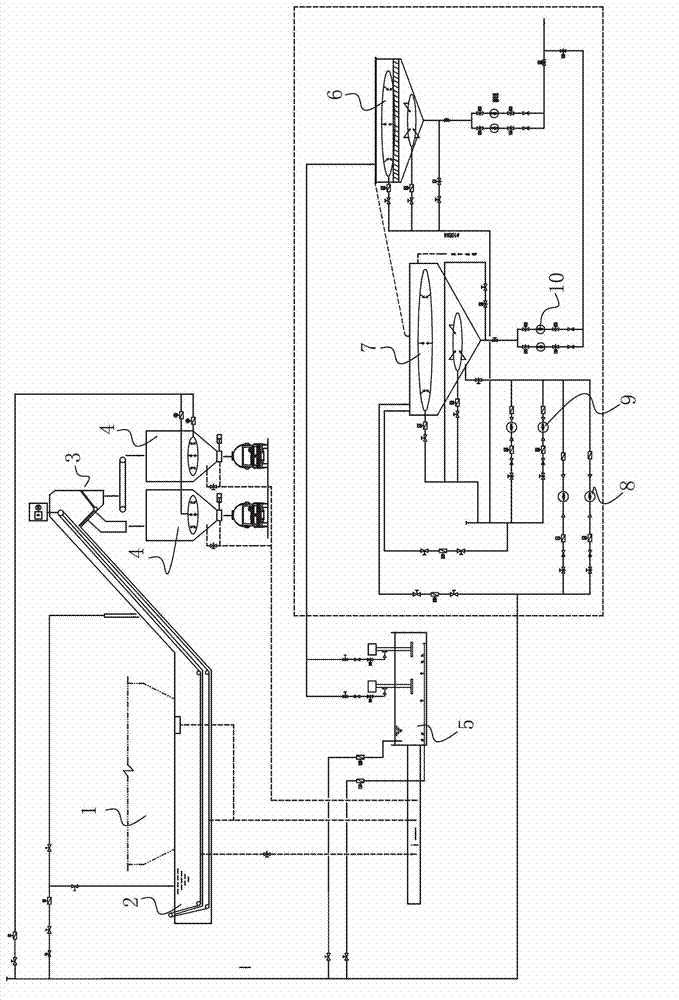

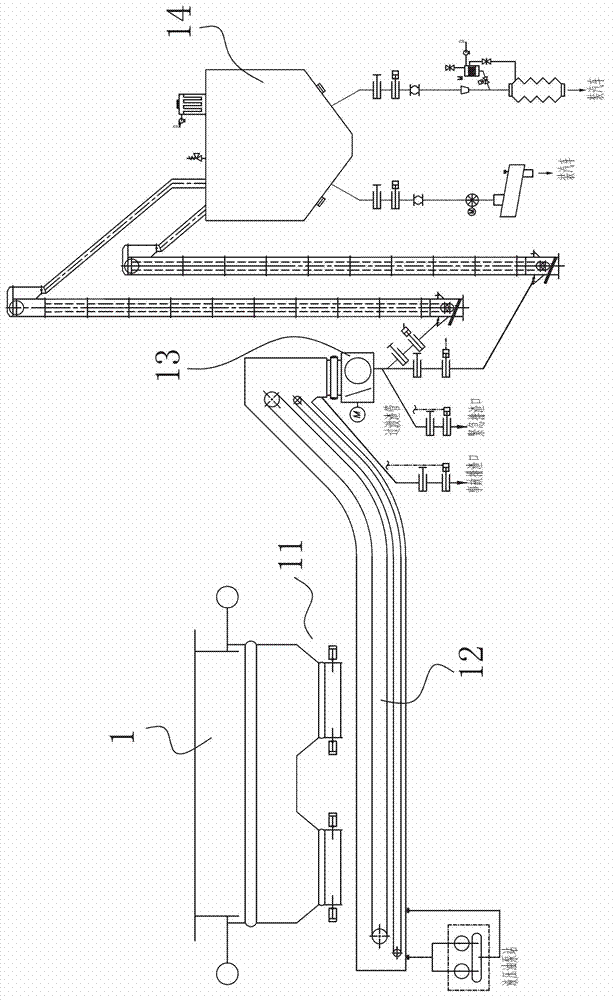

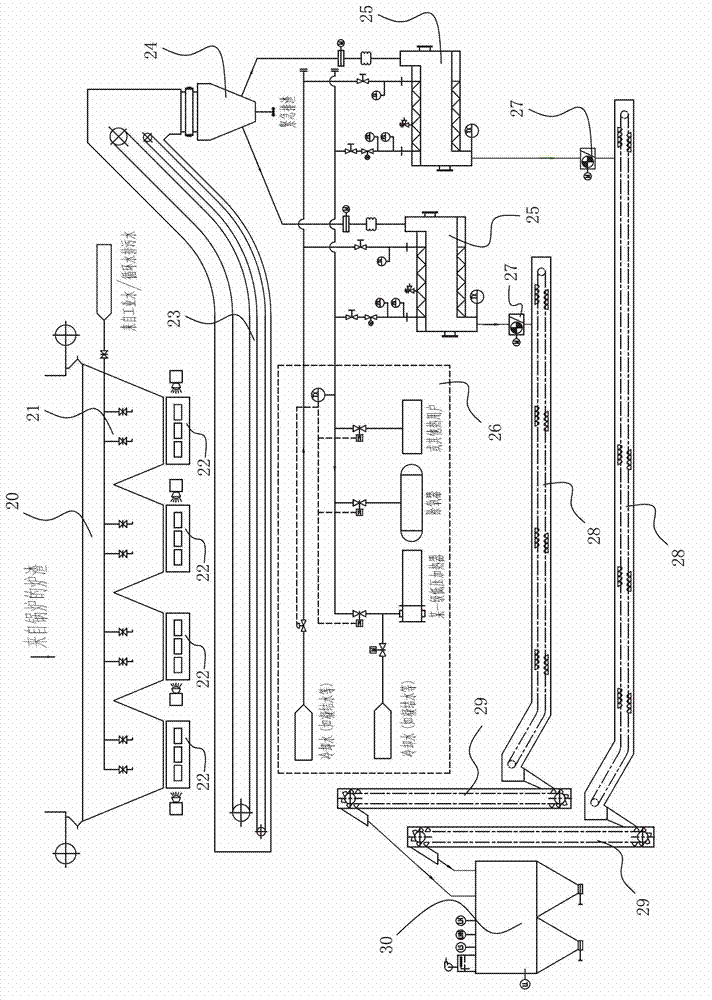

[0025] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0026] Hereinafter, main technical terms of the present invention will be described.

[0027] Pulverized coal boiler: a boiler that burns with pulverized coal as fuel.

[0028] Fengshui Combined Cooling: A cooling method that uses air and water as the cooling medium.

[0029] Dry slag discharge: slag is discharged from the boiler in a dry state for storage.

[0030] Water-cooled drum type slag cooler: installed at the bottom of the boiler slag well, using water as the cooling medium, indirect heat exchange, rotary cold slag dry slag removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com