Novel urea mixer

A technology of mixer and urea, which is applied in the field of power machinery, can solve the problems of higher nozzle atomization capacity, increased nozzle manufacturing cost, and increased nozzle manufacturing difficulty, so as to optimize structural layout, reduce production materials and costs, reduce The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the specific embodiments in the accompanying drawings.

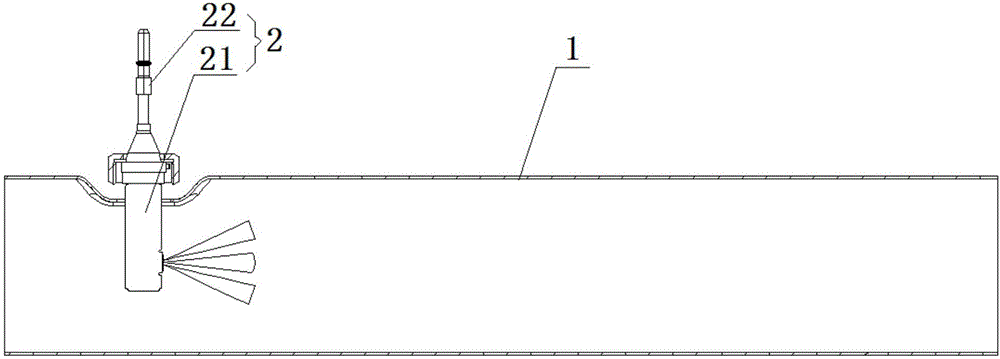

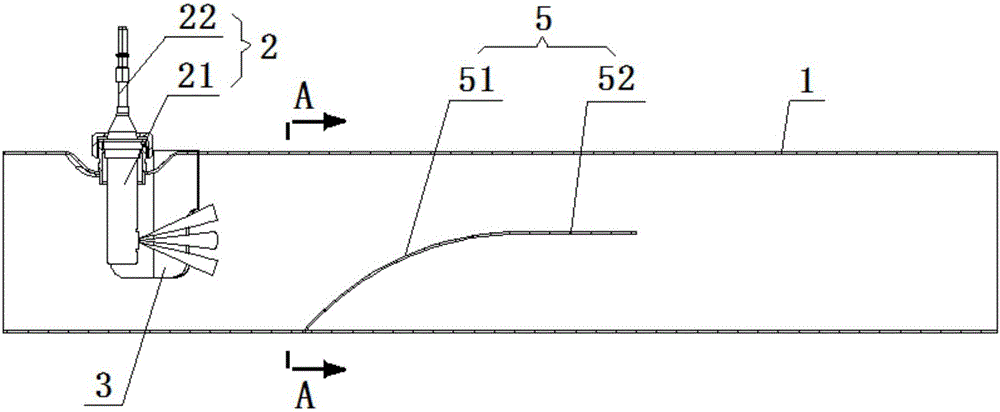

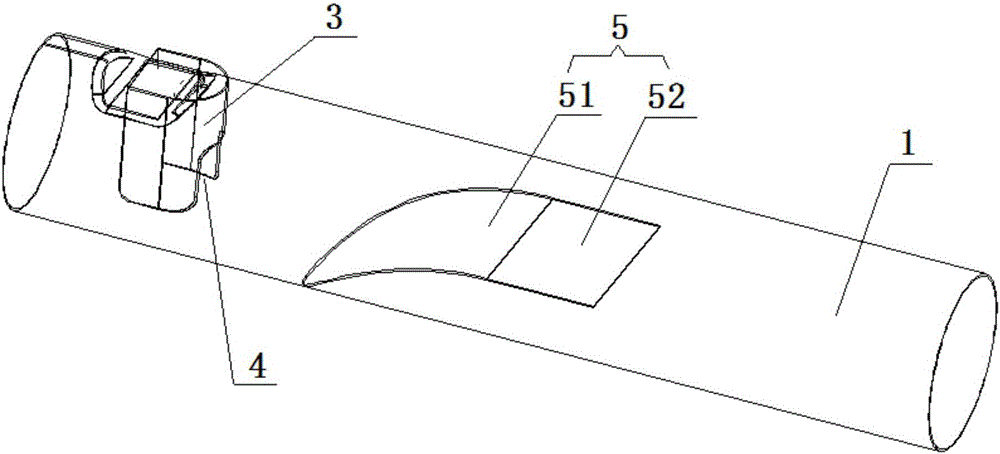

[0025] refer to Figure 1-4 , a new type of urea mixer of the present invention, including a mixing tube 1 for collecting urea and exhaust gas and a urea nozzle 2 vertically inserted at one end of the mixing tube 1, and a second urea nozzle surrounding the urea nozzle 2 is arranged in the mixing tube 1 A baffle 3, when the exhaust gas passes through the first baffle 3, the exhaust gas flow rate near the urea nozzle 2 can be increased, and the urea injected from the urea nozzle 2 will be blown away from the urea nozzle 2 at the fastest speed, reducing the amount of gas near the urea nozzle 2. At the same time, the first baffle 3 can disturb the exhaust gas flow, which enhances the mixing of the exhaust gas and urea; a gap 4 is provided on the side of the first baffle 3 opposite to the spraying direction of the urea nozzle 2, for urea The ure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com