Reaction tower for stack gas desulfurization of dry type circulating fluid bed

A circulating fluidized bed and reaction tower technology, which is applied in the field of flue gas purification, can solve the problems that the flue gas buffer chamber cannot be very large, affect the stable operation of the equipment, and is easy to block, and achieves compact structure, reduced floor space, and prevention of sticky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

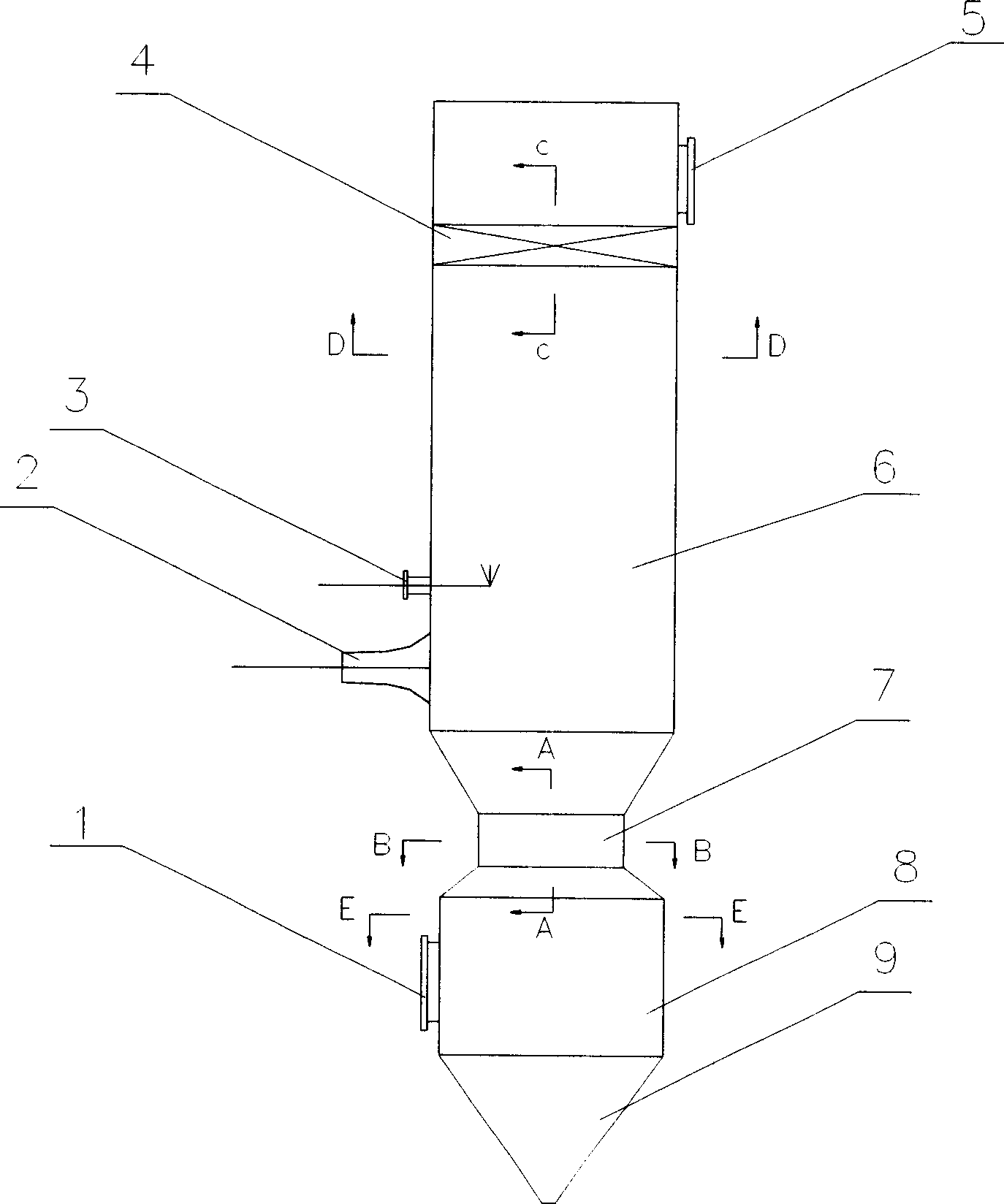

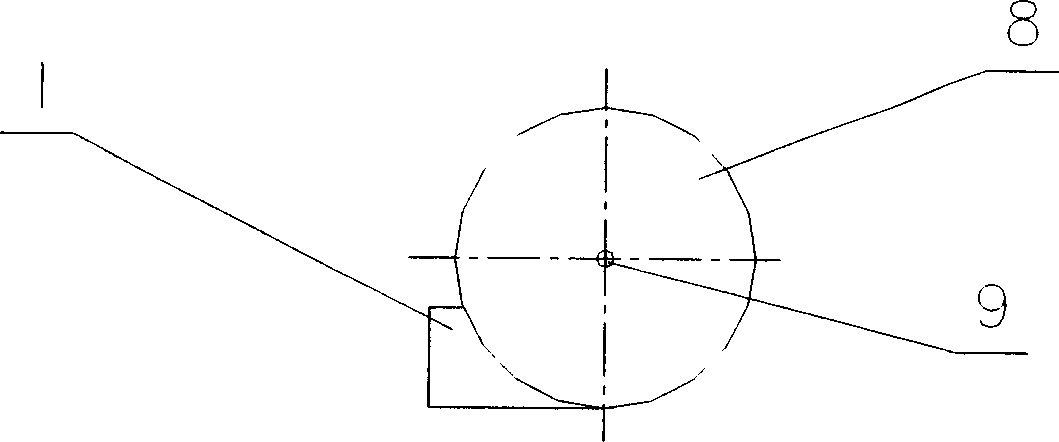

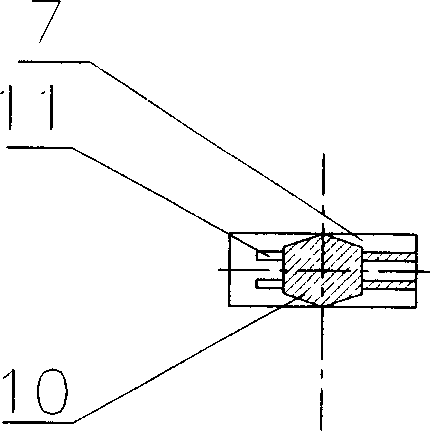

[0024] see Figure 1 to Figure 6 , the present invention includes a tower body and a flue gas inlet 1 connected to the tower body, a flue gas outlet 5, a water spray inlet 3 and a powder spray inlet 2. The tower body is composed of upper and lower sections, and the two sections are connected by the set Venturi section 7. The middle section of the Venturi section 7 has a blind area 10 built in, and the blind area 10 is fixed by a support rod 11 arranged on the throat wall of the Venturi section 7, and the upper and lower sections of the Venturi section 7 are cones. The lower section of the tower body is a pre-separation chamber 8 that acts as a buffer. The connection between the pre-separation chamber 8 and the flue gas inlet 1 adopts a tangential intake rotatable structure. The bottom of the pre-separation chamber 8 is a conical ash drop port 9 . The upper section of the tower body is a straight section 6, and the lower part of the straight section 6 is connected to the powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com