Rotary water-distributing type IC anaerobic reactor

An anaerobic reactor and rotary water distribution technology, applied in anaerobic digestion treatment, chemical instruments and methods, biological water/sewage treatment, etc. The effect of saving energy consumption and maintaining activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

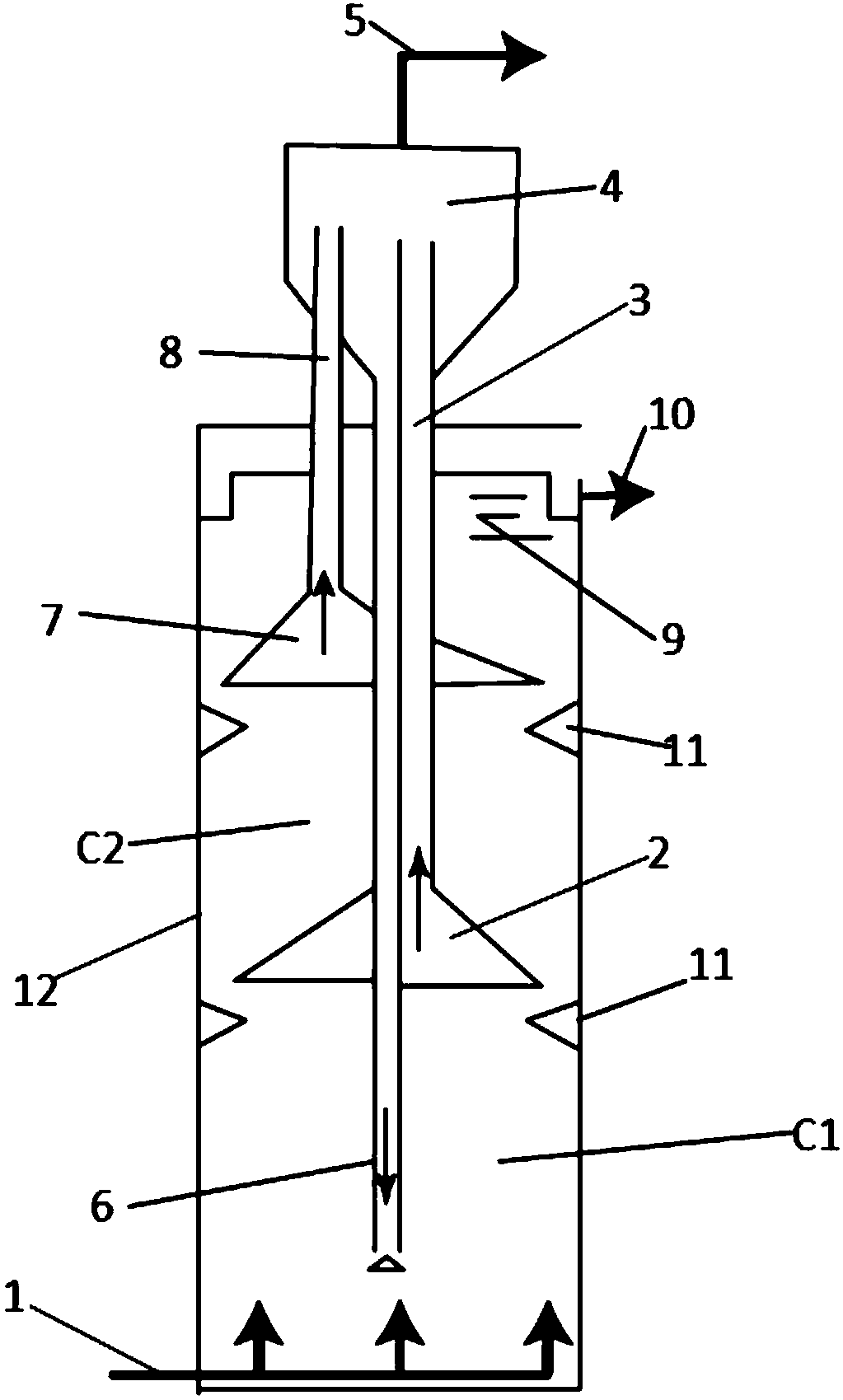

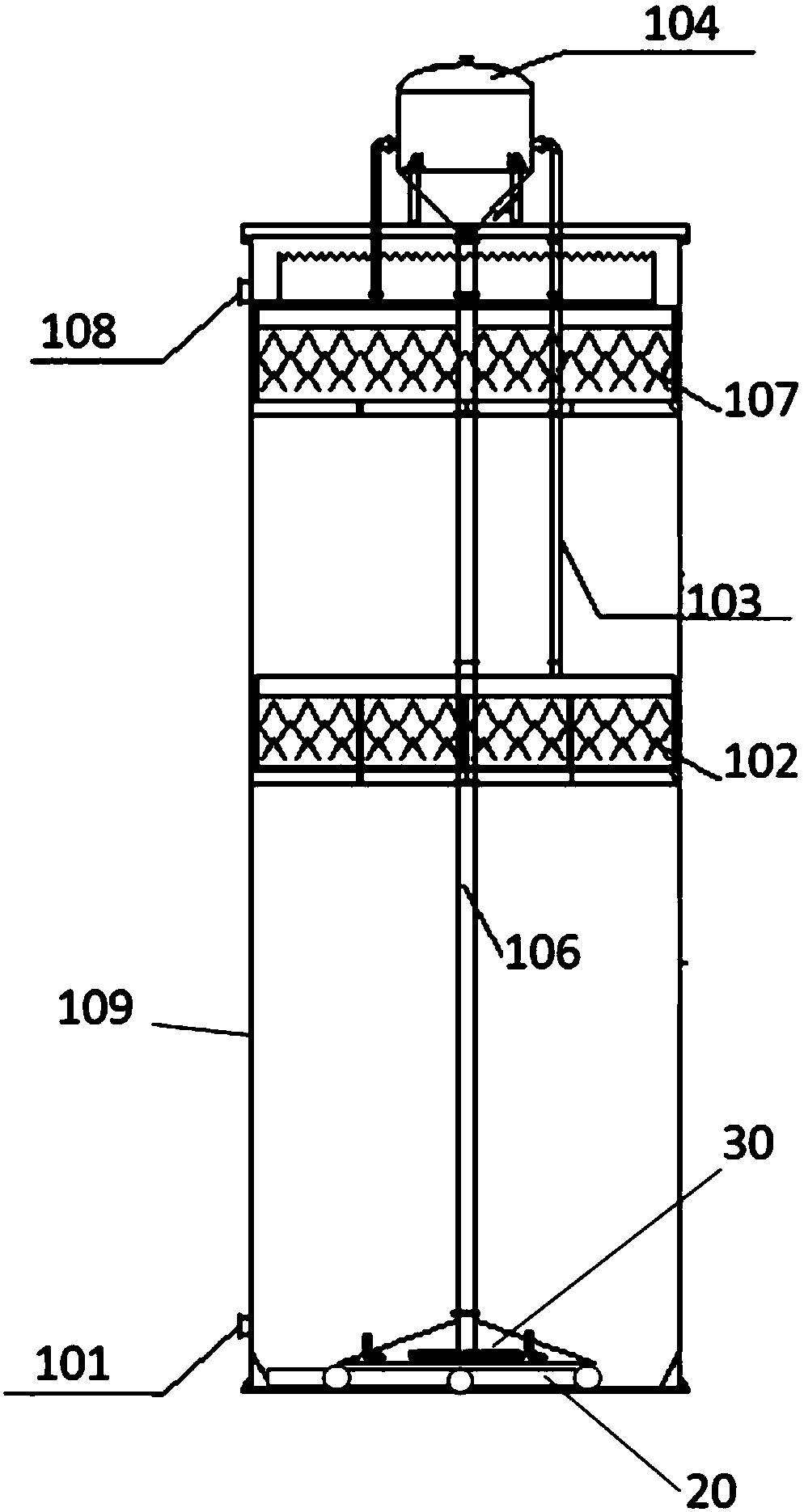

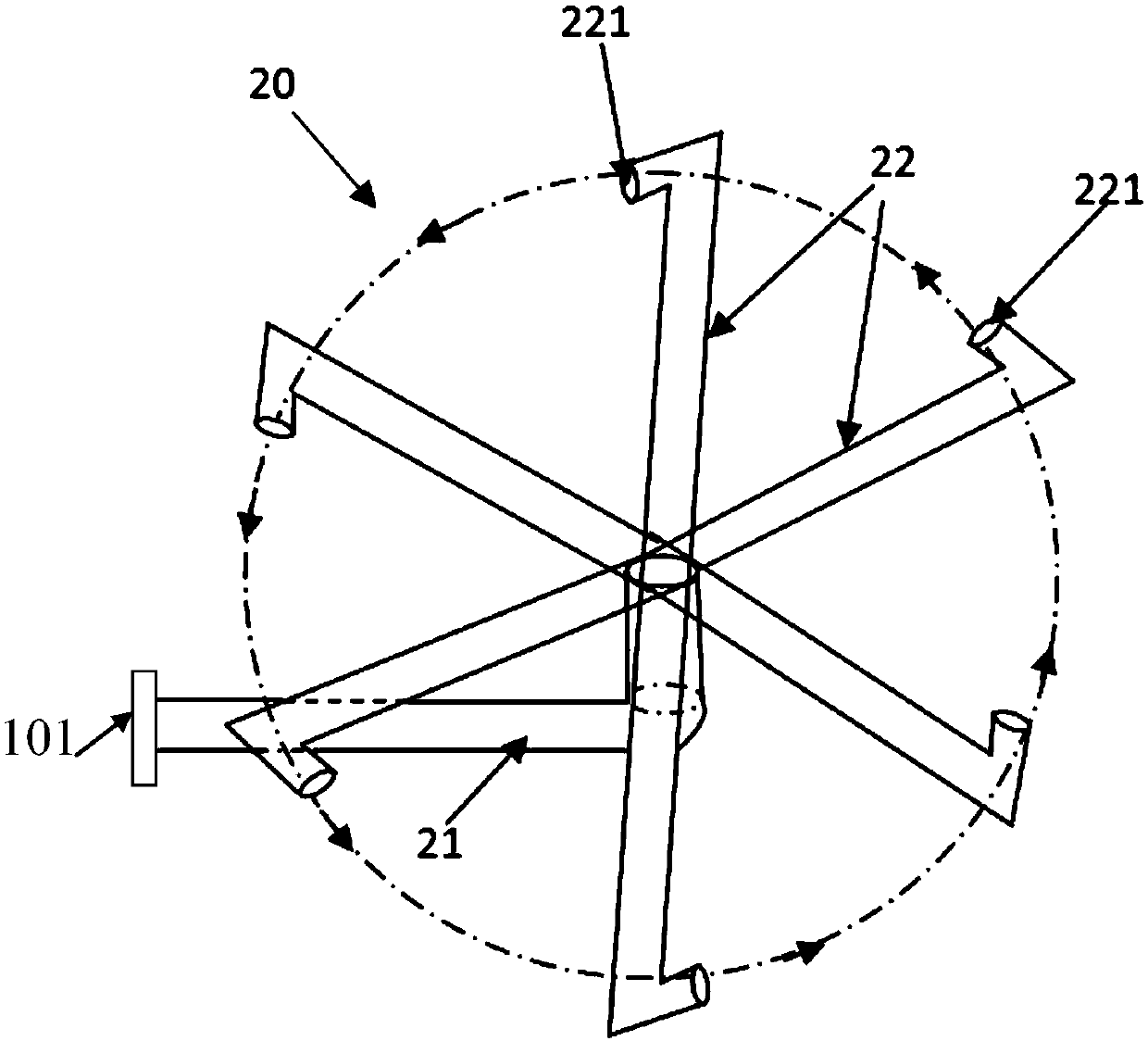

[0047] Such as figure 2 and image 3 Shown, the rotary water distribution type IC anaerobic reactor of an embodiment of the present invention, it comprises: reaction tower 109, and its bottom is provided with water inlet 101, and its top is provided with drain outlet 108, and in reaction tower 109, from bottom to top successively There are water inlet water distribution device 20, return water distribution device 30, internal return pipe 106, first three-phase separator 102, second three-phase separator 107, gas-water separator 104, wherein the upper end of internal return pipe 106 is connected The gas-water separator 104, the lower end of the internal return pipe 106 is towards the bottom of the reaction tower 109; the upper side of the first three-phase separator 102 and the second three-phase separator 107 are respectively connected to a biogas collector Pipe 103, the biogas collection pipe 103 communicates with the gas-water separator 104 above the reaction tower 109. T...

Embodiment 2

[0050] Such as Figure 4 Shown is yet another embodiment of the present invention. The difference between this embodiment and Embodiment 1 is that on the basis of Embodiment 1, the traditional backflow water distribution device 30 is improved, and at the same time, the backflow water distribution device 30 and the inlet water distribution device 20 are synergistic and mutually promoted role.

[0051] See Figure 4 As shown, the return water distribution device 30 has a similar structure to the inflow water distribution device 20 . The return water distribution device 30 is connected to the lower end of the inner return pipe 106 . The backflow water distribution device 30 includes two or more sub-pipes 31 radially arranged, and the sub-pipes are provided with backflow holes 311, wherein the backflow holes 311 all face counterclockwise or all face clockwise , and the direction of the return hole 311 is the same as that of the water inlet hole 221 of the water inlet and distr...

Embodiment 3

[0054] Embodiment 3 is based on Embodiment 1, and does not limit the inlet water distribution device 20, but only improves the return water distribution device 30 as in Embodiment 2, that is, the return water distribution device 30 is connected to the inner return pipe 106 lower end. The backflow water distribution device 30 includes two or more sub-pipes 31 radially arranged, and the sub-pipes are provided with backflow holes 311, wherein the backflow holes 311 all face counterclockwise or all face clockwise .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com