Ultrasonic reinforced micro-channel heat exchanger

An ultrasonic and micro-channel technology, which is applied in electric solid devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of inability to apply microelectronic heat dissipation, large volume of shell-and-tube heat exchangers, and relatively high cooling fluid requirements. It can reduce the kinematic viscosity coefficient, enhance the operation reliability, and enhance the heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

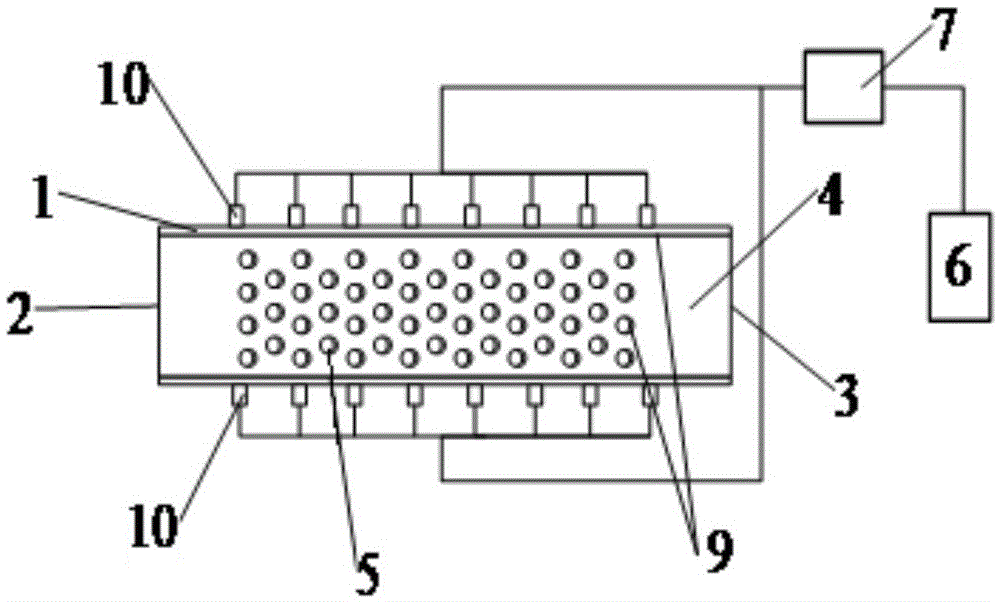

[0025] like figure 1 As shown, the ultrasonically enhanced micro-channel heat exchanger of this embodiment includes a heat dissipation shell, a water cooling system, a microneedle rib 5, an ultrasonic generator 6, an ultrasonic transducer 7 and an ultrasonic transducer vibrator 10;

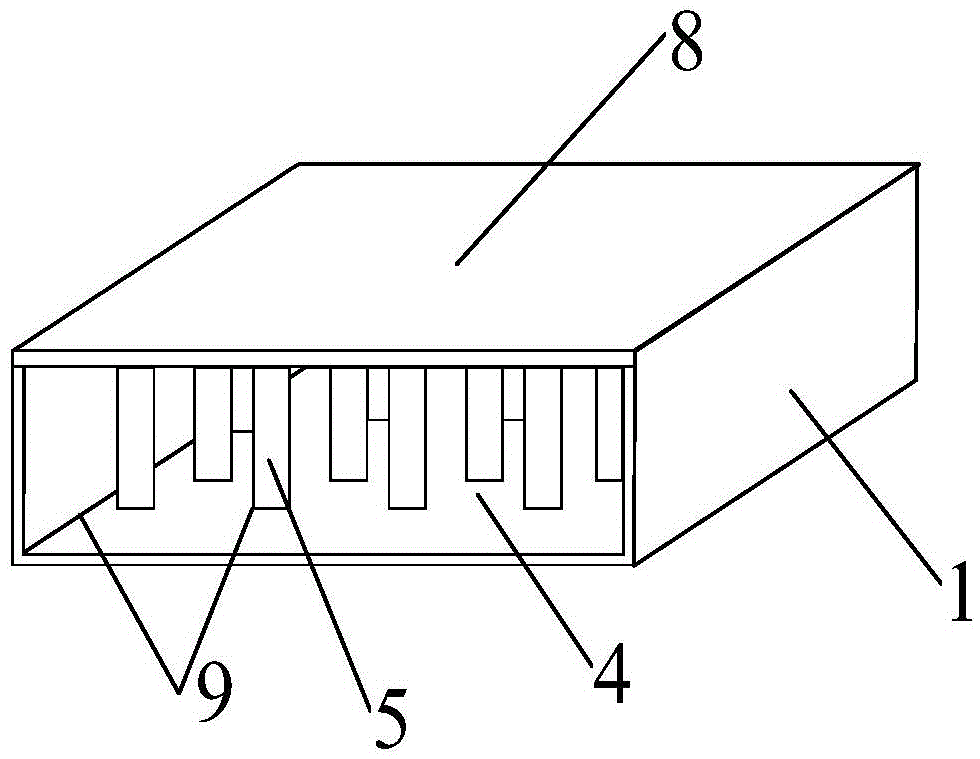

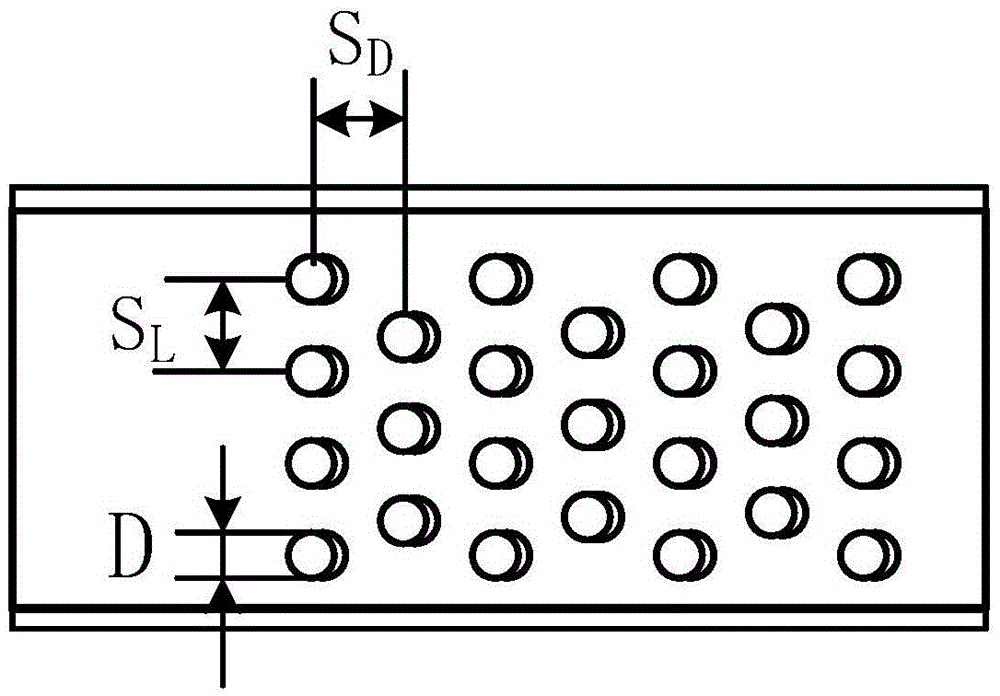

[0026] Wherein, the water cooling system includes a cooling water channel 4, a water inlet 2 and a water outlet 3, the cooling water channel 4 is arranged inside the heat dissipation housing, and the cross section of the cooling water channel 4 is rectangular (see for details figure 2 ), the water inlet 2 and the water outlet 3 are respectively arranged on the heat dissipation housing, and the water inlet 2 and the water outlet 3 are respectively connected with the cooling channel 4 to form a water cooling system; the cooling medium can be deionized water or ethanol, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com