Immersed vacuum membrane distillation plant and sewage treatment technology using the same

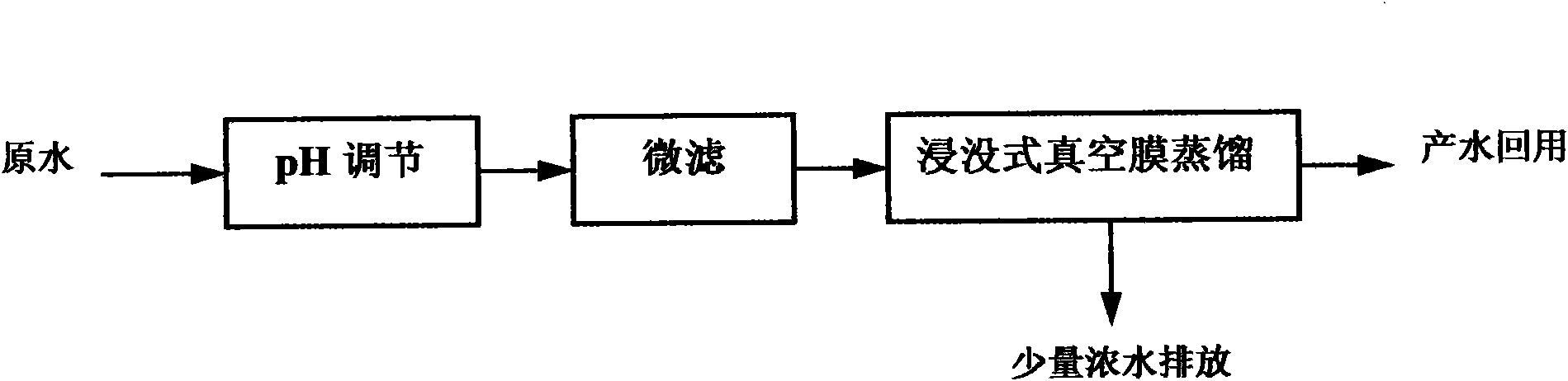

A vacuum membrane distillation and immersion technology, applied in water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of reduced vacuum on the permeate side and increased energy consumption. Achieve the effects of reducing concentration polarization, solving easy pollution and clogging, and improving heat utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

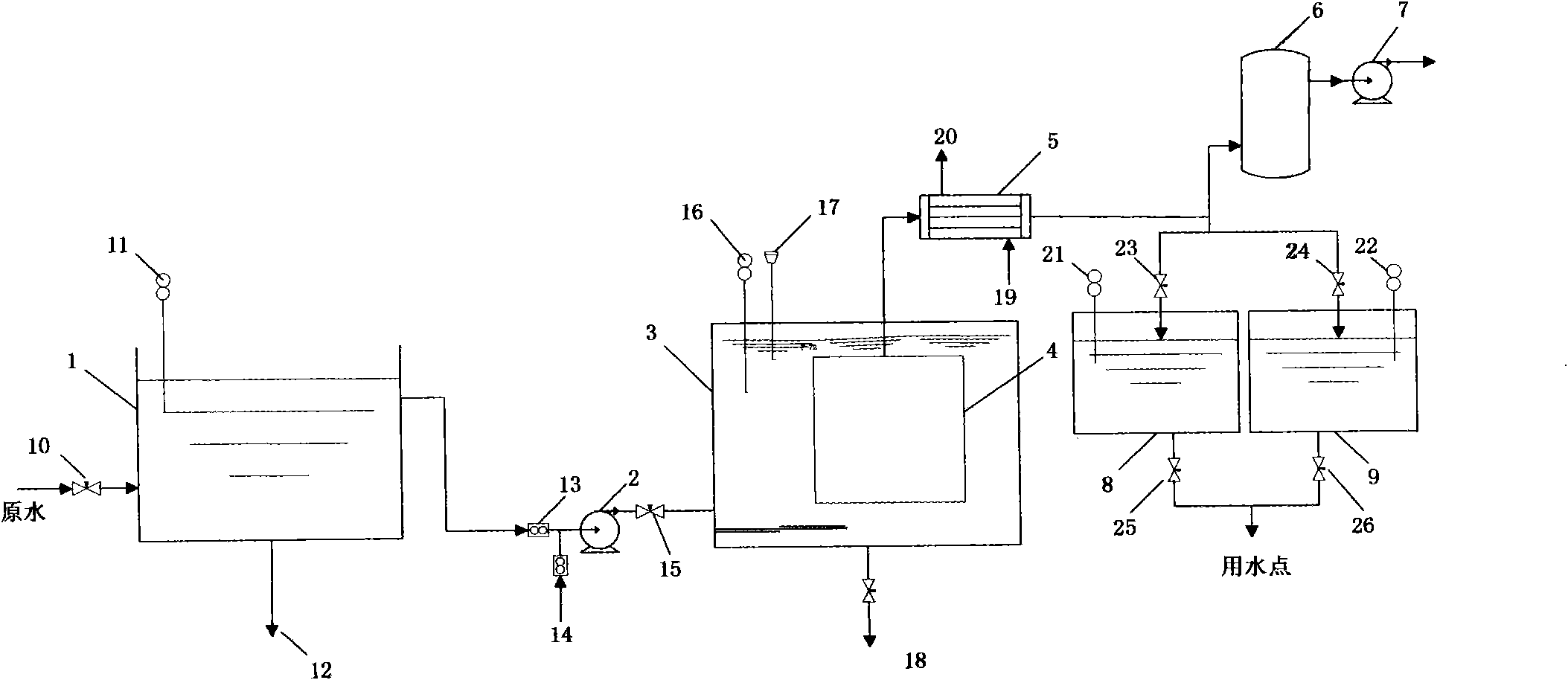

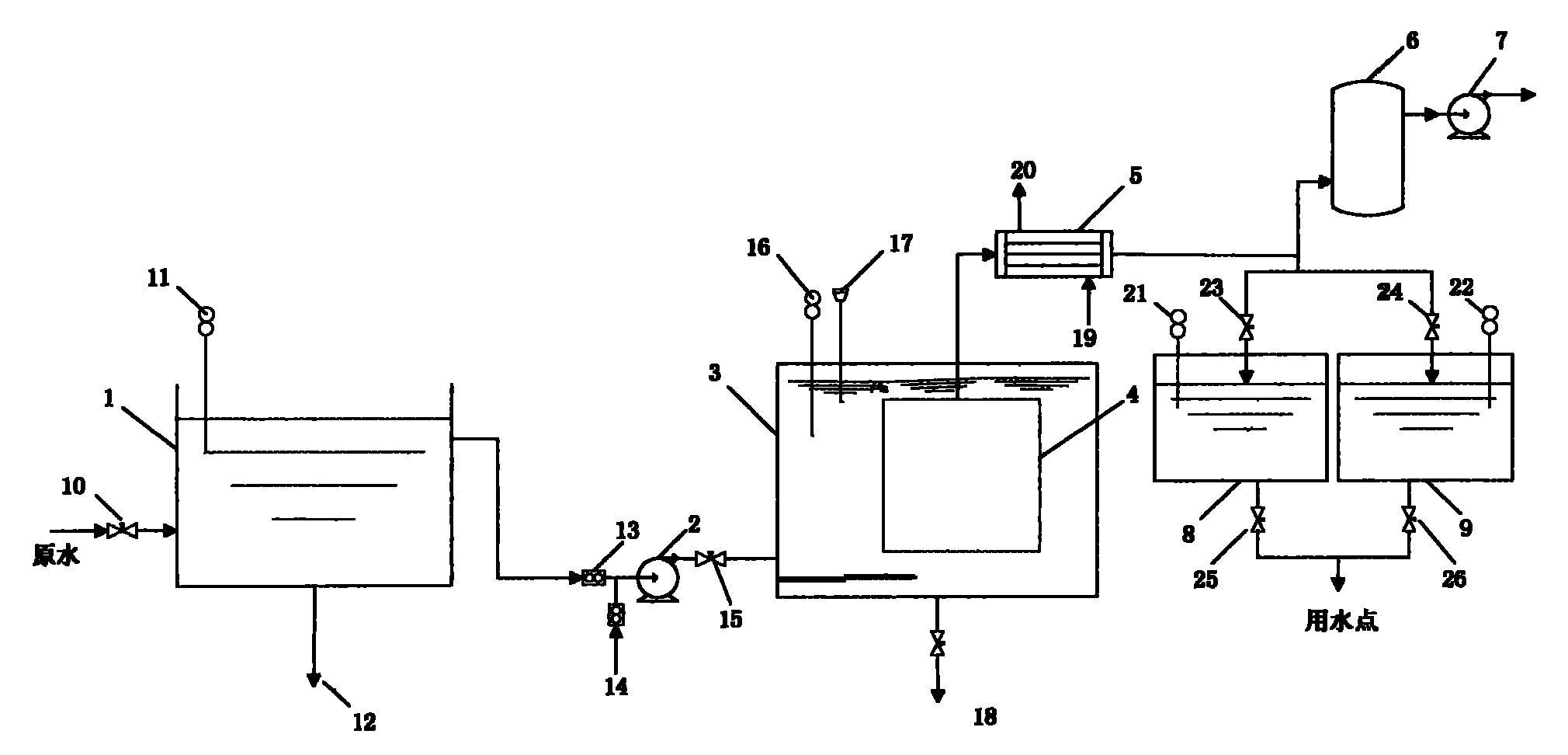

[0078] The submerged vacuum membrane distillation device consists of: raw water storage tank 1, dissolved air pump 2, raw water heating tank 3, membrane distillation hydrophobic membrane module 4, condenser 5, vacuum buffer tank 6, vacuum pump 7, produced water tanks 8 and 9, raw water Opening regulating valve 10, raw water storage tank liquid level gauge 11, raw water storage tank mud outlet 12, water inlet liquid flowmeter 13, gas flowmeter 14, opening regulating valve 15, raw water heating water tank level gauge 16, raw water heating Water tank exhaust port 17, raw water heating water tank concentrated water discharge port 18, circulating condensed water inlet 19, circulating condensed water outlet 20, produced water tank 8 liquid level gauge 21, produced water tank 9 liquid level gauge 22, produced water tank 8 inlet solenoid valve 23 , 8 outlet solenoid valves 25 of the water production tank, 9 inlet solenoid valves 24 of the water production tank, 9 outlet solenoid valves...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com