A method for concentrating chlor-alkali anode light brine

A light brine and anode technology, applied in the field of anode light brine, can solve the problems of high efficiency and low energy consumption of light brine concentration and reuse, and achieve the effects of reducing energy consumption and chemical consumption, improving concentration efficiency, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

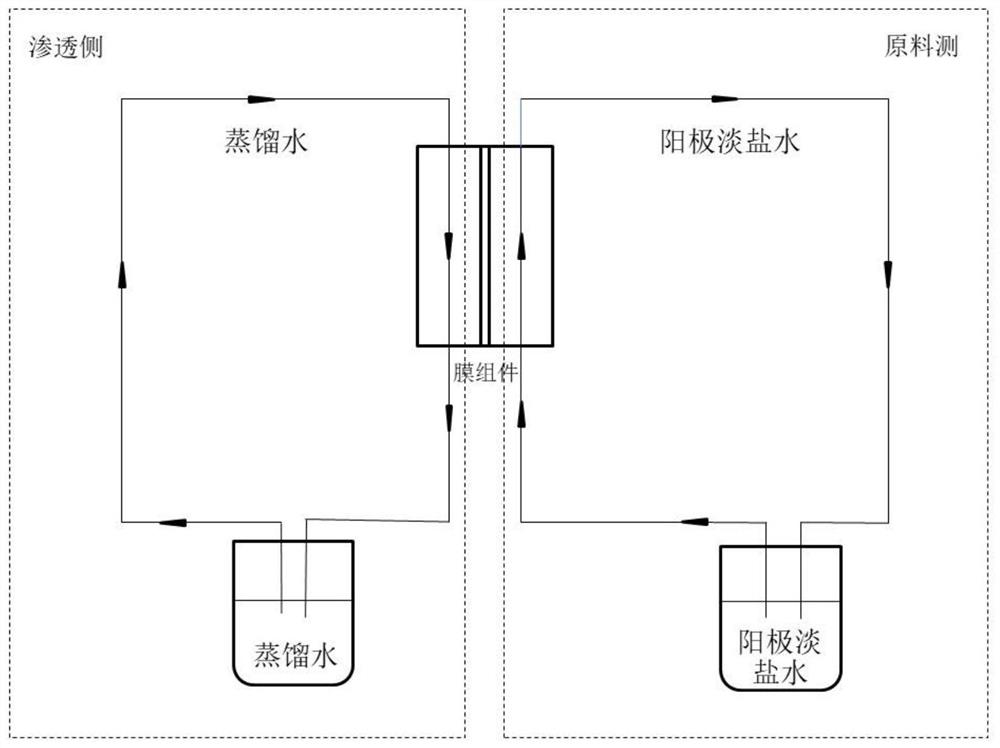

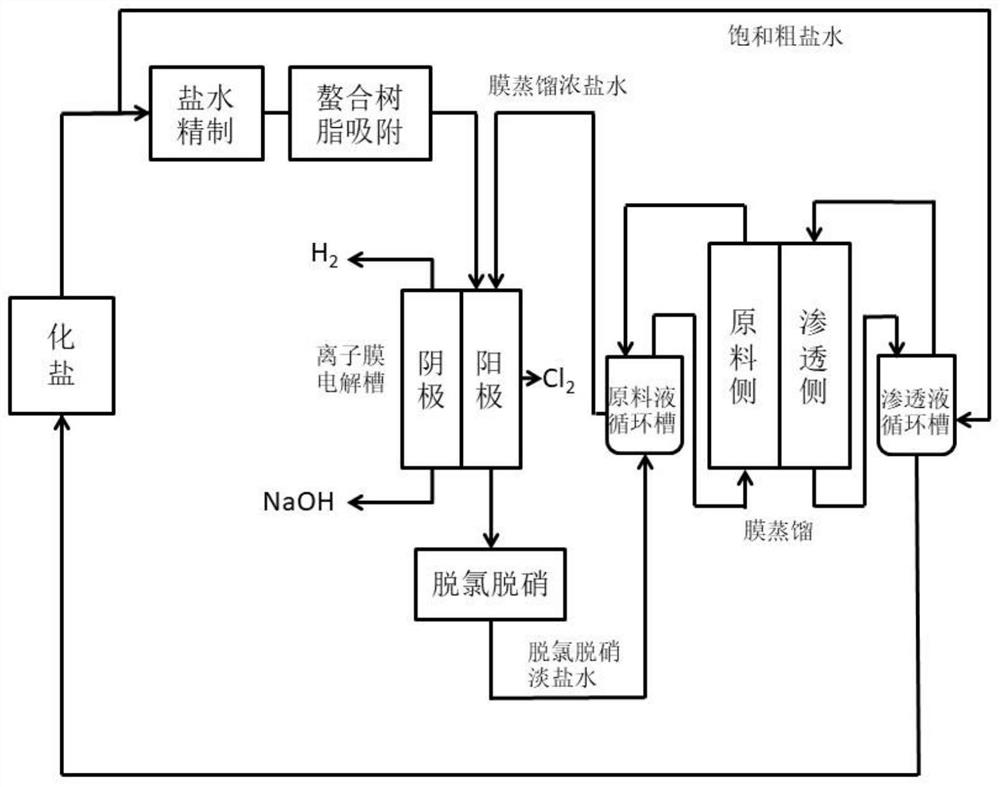

[0048] The invention provides a method for concentrating chlor-alkali anode brine. According to the production requirements, the anode brine electrolyzed from an ion-exchange membrane electrolyzer is dechlorinated and denitrified, and then entered into a raw material solution storage tank of a membrane distillation system, and obtained after desalination. The saturated crude brine enters the permeate storage tank of the membrane distillation system.

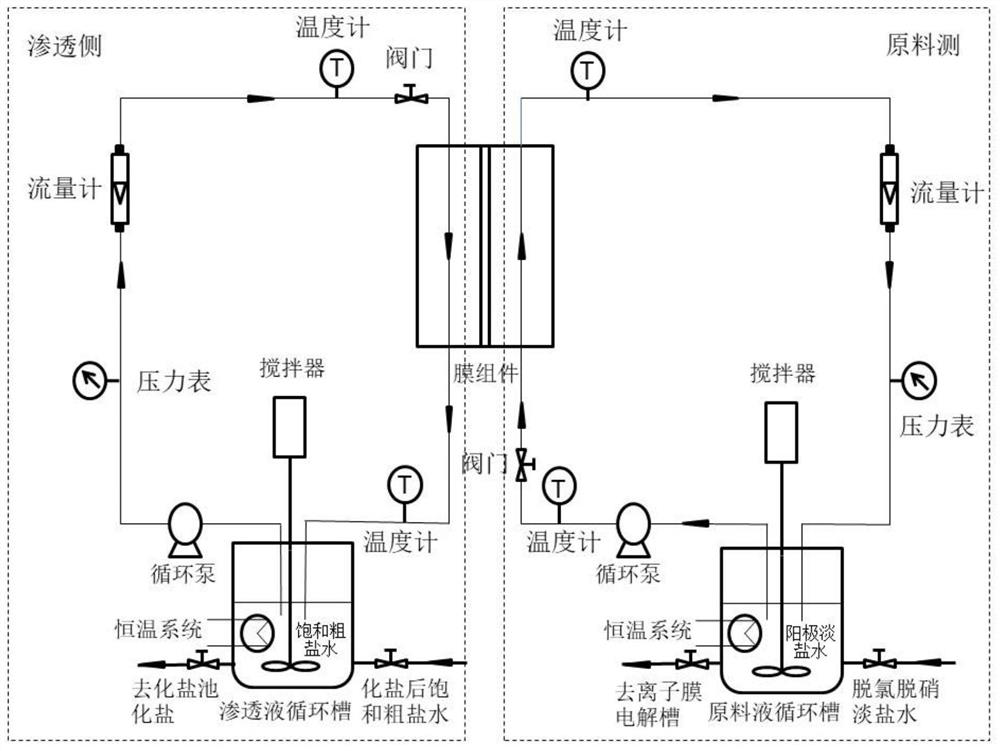

[0049] (1) Pass the anode light brine into the raw material liquid storage tank of the membrane distillation system, the concentration of sodium chloride in the light brine is 180g / L, no free chlorine, and the temperature is 50°C.

[0050] (2) Pass the saturated crude brine after desalting into the permeation side of the membrane distillation system, the concentration of saturated crude brine NaCl is 310g / L, Ca 2+ , Mg 2+ and SO 4 2- The concentration of other hetero ions is lower than 10g / L, and the temperature is 20°C.

[0...

Embodiment 2

[0055] The operation steps of Example 2 are the same as those of Example 1. The difference from Example 1 is that in order to further shorten the concentration time of the anode brine, the flow rate of the feed liquid on both sides of the membrane module is adjusted to 600mL / min, and the running time can be shortened to 40 minutes. The composition of the final light brine is shown in Table 2. The concentrated light brine enters the ion-exchange membrane electrolyzer to realize the reuse of the anode light brine.

[0056] The invention utilizes the osmotic membrane distillation technology to concentrate the anode brine. Membrane distillation uses a hydrophobic microporous membrane, and uses the vapor pressure difference on both sides of the membrane as the driving force for mass transfer, so as to achieve efficient concentration and treatment of the solution. Especially in areas rich in waste heat, solar energy and geothermal resources, membrane distillation technology is consi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com