Gas-disturbance type membrane distilling method and membrane distilling device

A technology of membrane distillation and hydrophobic membrane, which is applied in chemical instruments and methods, pervaporation, membrane technology, etc., can solve the problems of not developing a high distillation flux membrane, unstable operation state, and affecting the service life of the membrane, so as to reduce the Effects of membrane fouling, easy maintenance, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

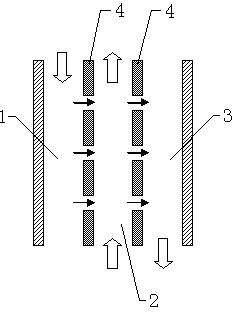

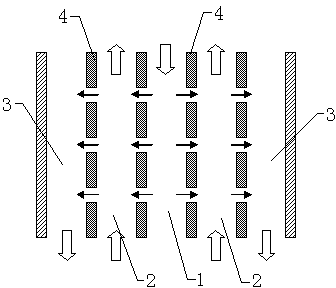

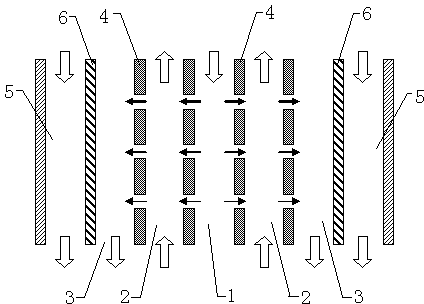

[0029] A method for air-disturbed membrane distillation, the method is that: compressed air enters the hot-side solution chamber through a hydrophobic membrane from one side of the hot-side solution chamber of the membrane distillation device, and generates a Perturbation in the direction perpendicular to the hydrophobic membrane; then the air entering the hot side solution chamber and the vapor of the purified product pass through the hydrophobic membrane from the hot side solution chamber into the cold side purification chamber located on the other side of the hot side solution chamber; finally the purification things to collect. The above-mentioned hydrophobic membrane adopts a flat membrane, and the hydrophobic membrane can only pass through air and steam of the purified substance, but cannot pass through liquid.

[0030] Such as Figure 1-5 Shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com