Reverse osmosis concentrated water dissolved gas type vacuum membrane distillation water processing method

A technology of reverse osmosis concentrated water and membrane distillation, applied in osmosis/dialysis water/sewage treatment, heating water/sewage treatment, etc. Realize the effect of resource utilization, reducing condensation and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

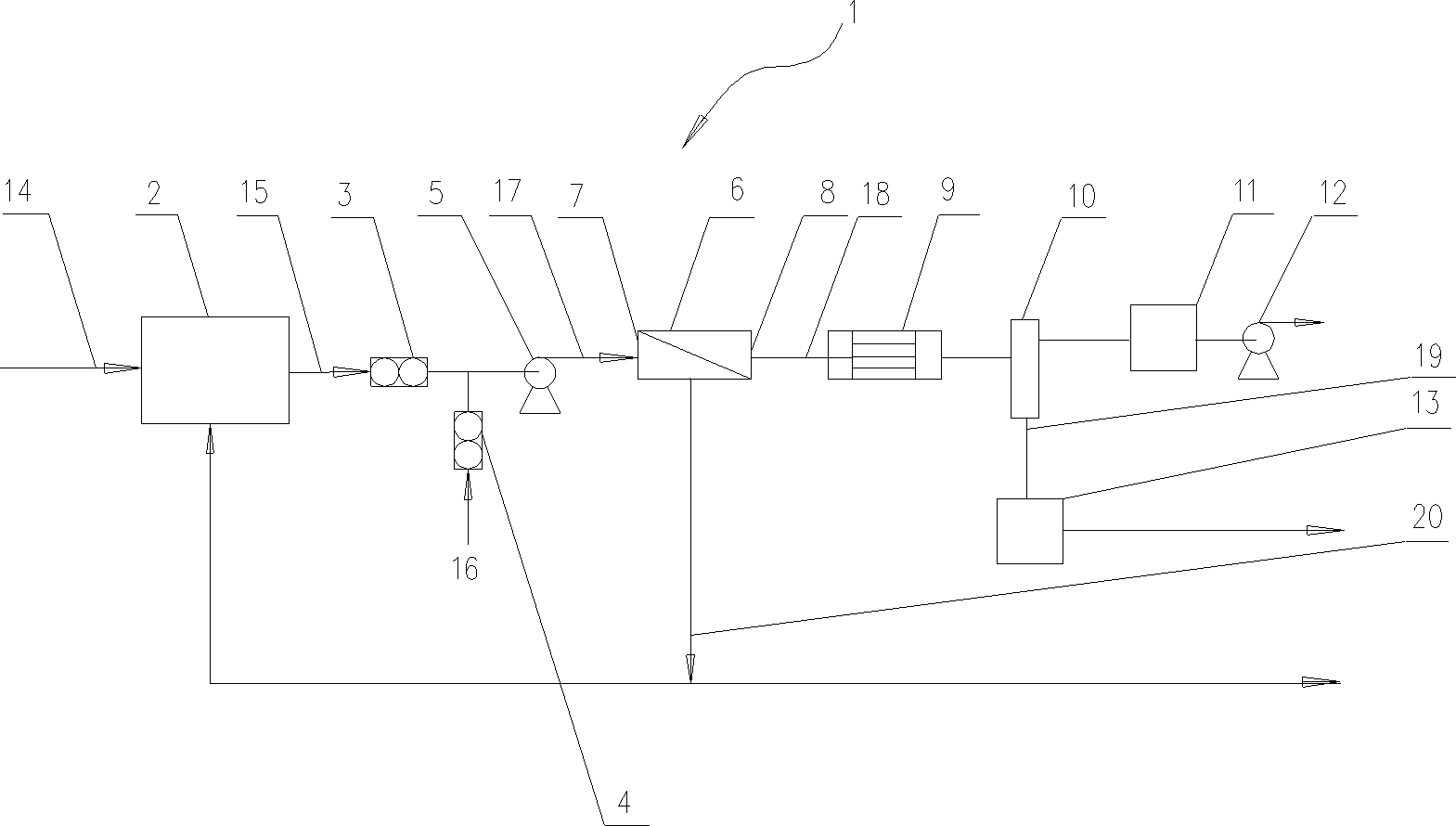

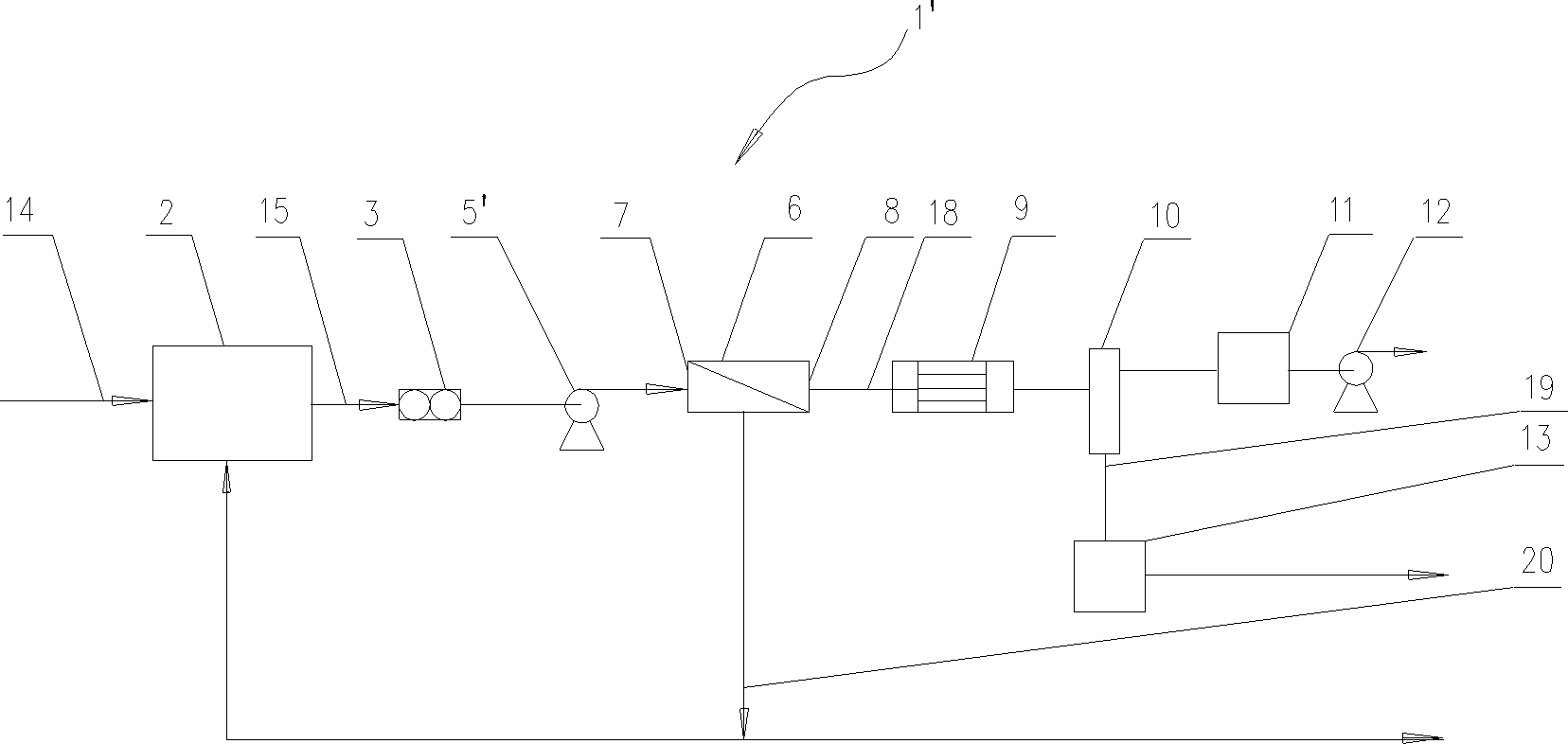

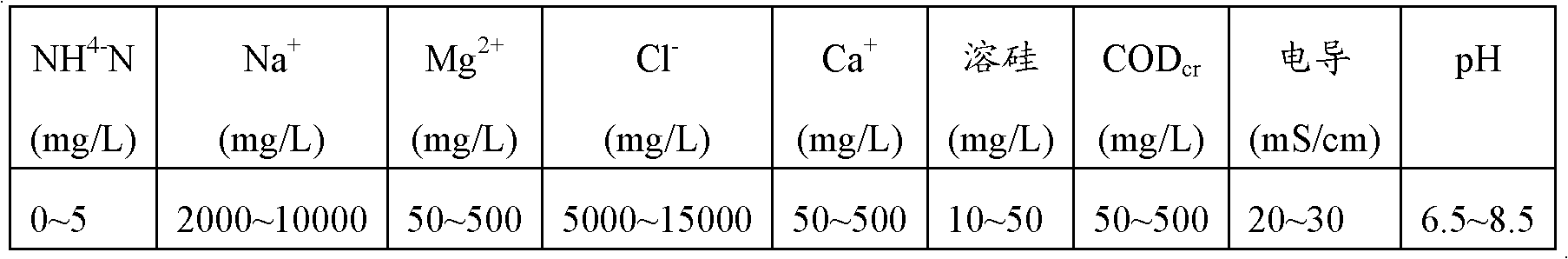

[0039] The reverse osmosis concentrated water of olefin polymerization catalyst production wastewater in a petrochemical enterprise, the main water quality characteristics are: sewage pH8, conductivity 25mS / cm, COD Cr 242mg / L, Ca 2+ 214mg / L, Mg 2+ 227mg / L, Na + 5078mg / L, Cl - 8407mg / L, dissolved silicon 36mg / L, NH 4 -N2 mg / L. For a schematic diagram of the process, see figure 1 .

[0040] The membrane distillation module used is a polyvinylidene fluoride hollow fiber hydrophobic membrane module with a membrane pore size of 0.2 μm. The process is as follows: First, the concentrated reverse osmosis water of the olefin polymerization catalyst production wastewater with a pH of 8 at the feed end enters the heating water tank and is heated to a predetermined temperature of 75°C to obtain feed water at 75°C; secondly, the feed water at 75°C is dissolved into the Air with a gas-liquid volume ratio of 0.08:1 forms a water-gas-liquid mixture, and the amounts of water and air are...

Embodiment 2

[0043] The main water quality characteristics of the reverse osmosis concentrated water of the olefin polymerization catalyst production wastewater are the same as in Example 1. For a schematic diagram of the process, see figure 1 .

[0044] The membrane distillation process of Example 2 is different from Example 1 in that: the influent water at 65°C is dissolved with air with a gas-liquid volume ratio of 0.12:1 to form a gas-liquid mixture of influent water, and other membrane distillation treatment conditions are the same as in Example 1.

[0045] The membrane distillation treatment effect of reverse osmosis concentrated water is shown in Table 2.

Embodiment 3

[0047] The main water quality characteristics of the reverse osmosis concentrated water of the olefin polymerization catalyst production wastewater are the same as in Example 1. For a schematic diagram of the process, see figure 1 .

[0048] The membrane distillation process of Example 3 is different from Example 1 in that: air with a gas-liquid volume ratio of 0.12:1 is dissolved in the influent water to form a gas-liquid mixture in the influent water, and other membrane distillation treatment conditions are the same as in Example 1.

[0049] The membrane distillation treatment effect of reverse osmosis concentrated water is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com