Membrane evaporating and concentrating method and device

A concentration device and membrane evaporation technology, which is applied in the direction of total evaporation, can solve the problems of membrane pollution, COD and other pollutants concentration increase, and high energy consumption in operation, so as to improve membrane distillation flux, easy automatic control, and improve concentration multiple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

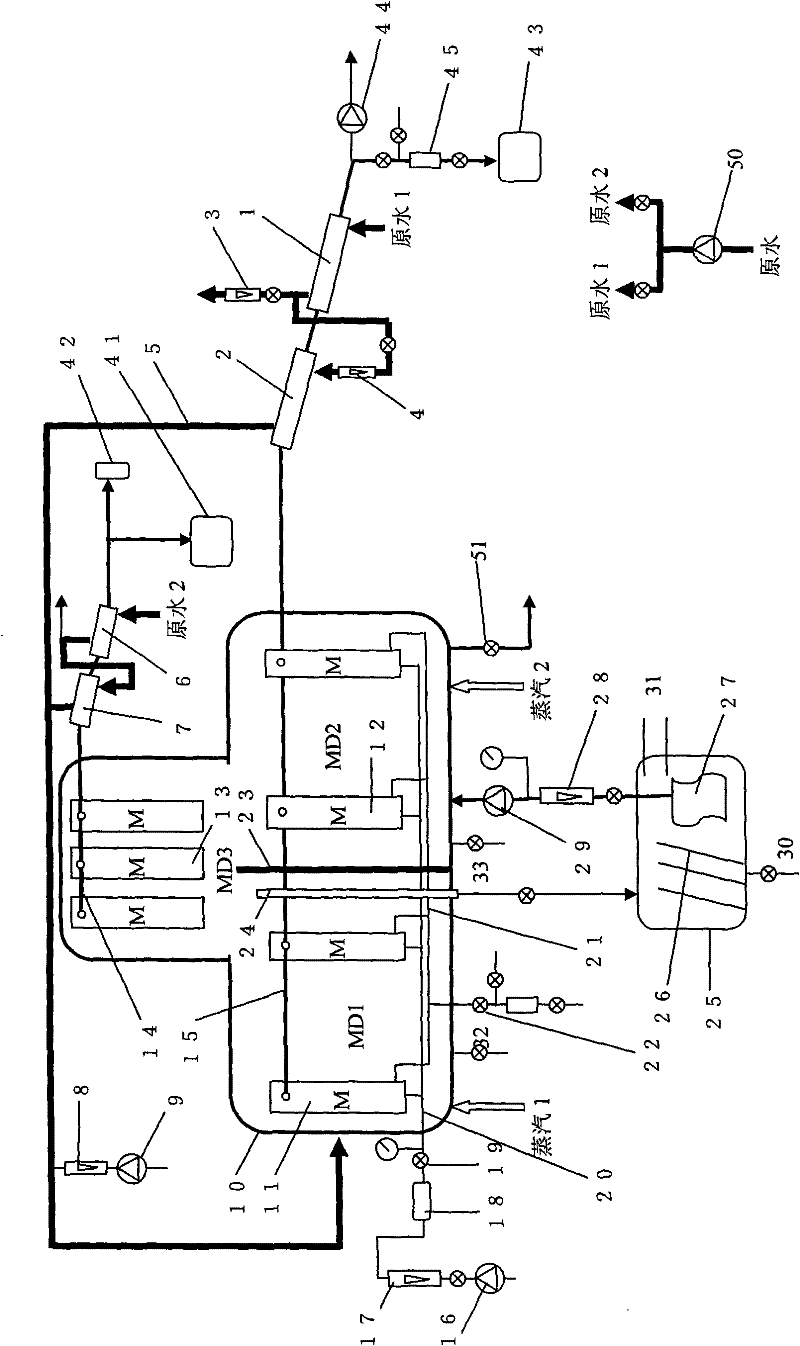

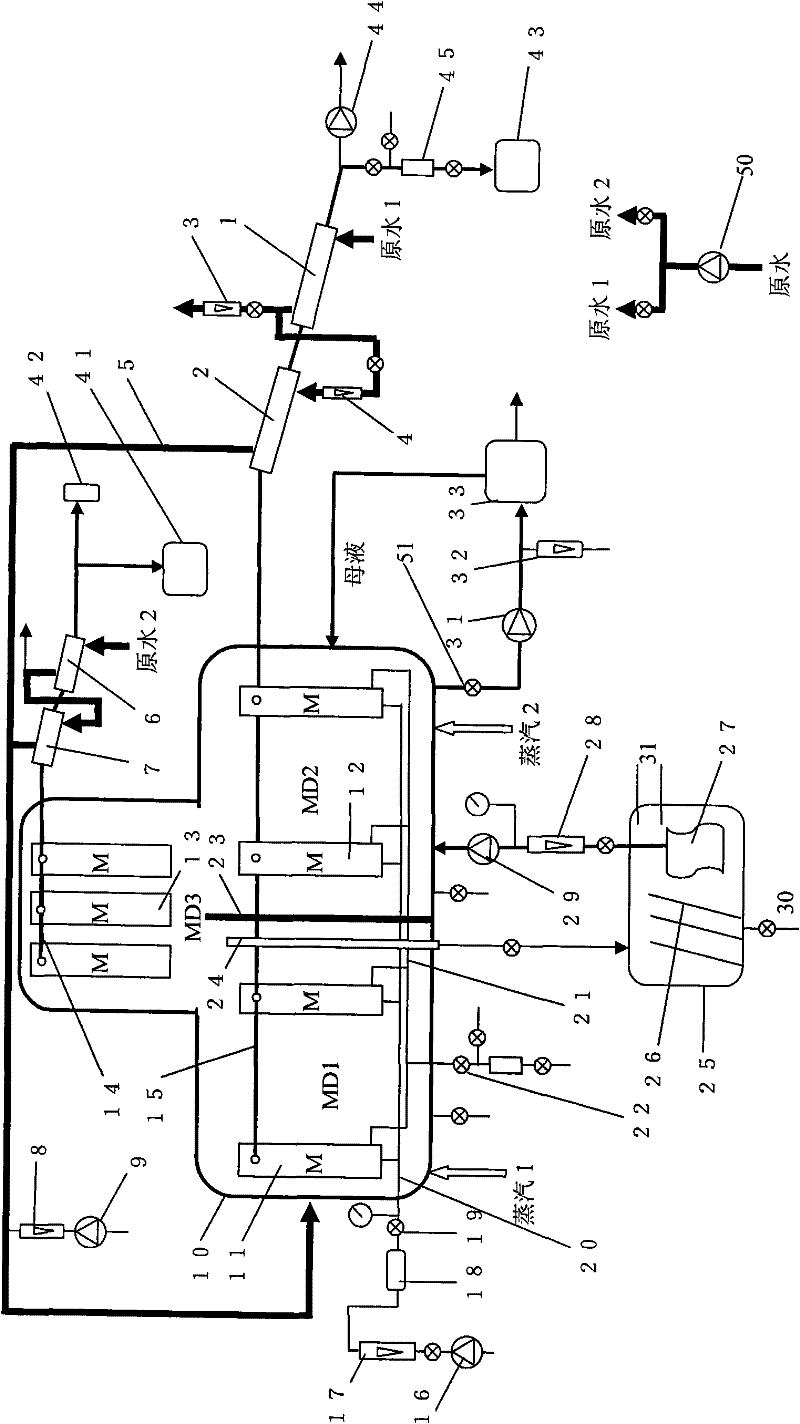

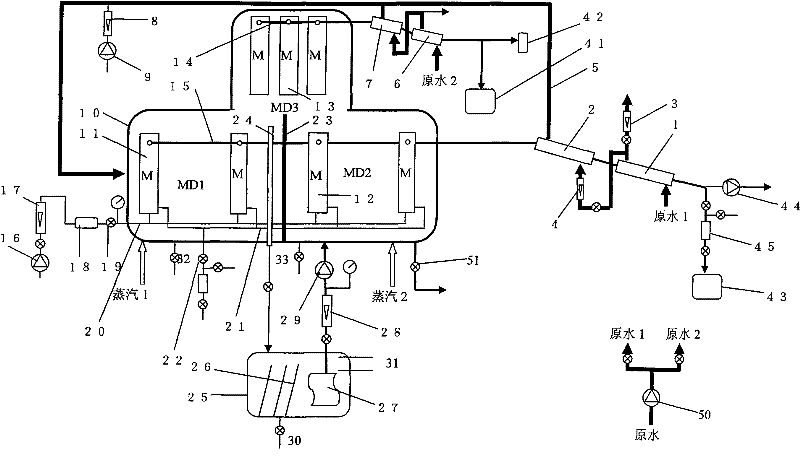

[0023] The system of the present invention is as figure 1 shown. The film evaporation and concentration device involved in the present invention comprises the following parts connected in sequence:

[0024] Raw water pump 50, membrane evaporation tank 10, hydrophobic membrane modules 11, 12, 13, blower 16, heat exchangers 1, 2, 6, 7, membrane filtration tank 25, pump 9, ultrafiltration membrane 27, water production tanks 41, 43 , vacuum pump 44, flowmeter 3, 4, 8, 17, 28, 32, inclined plate 26, membrane area MD1, MD2, MD3, partition 23, overflow pipe 24, electric heating cylinder 18, one-way valve 19, output Gas pipe 20, seepage liquid collection pipe 21, seepage liquid discharge valve 22, raw water inlet pipe 5, ultrafiltration suction pump 29, gas-liquid separator 45, etc.

[0025] The structure of the membrane evaporation concentration device of the present invention will be described in detail below.

[0026] The membrane evaporation and concentration device is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com