Immersed dissolved gas vacuum membrane distillation water processing method

A treatment method and vacuum membrane technology, which are applied in heating water/sewage treatment, permeation/dialysis water/sewage treatment, etc., can solve the problems of fouling at the inlet of membrane modules, reduced vacuum on the permeate side, and difficult cleaning of membrane modules, etc. To achieve the effect of small heat conduction loss, reducing heat loss and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

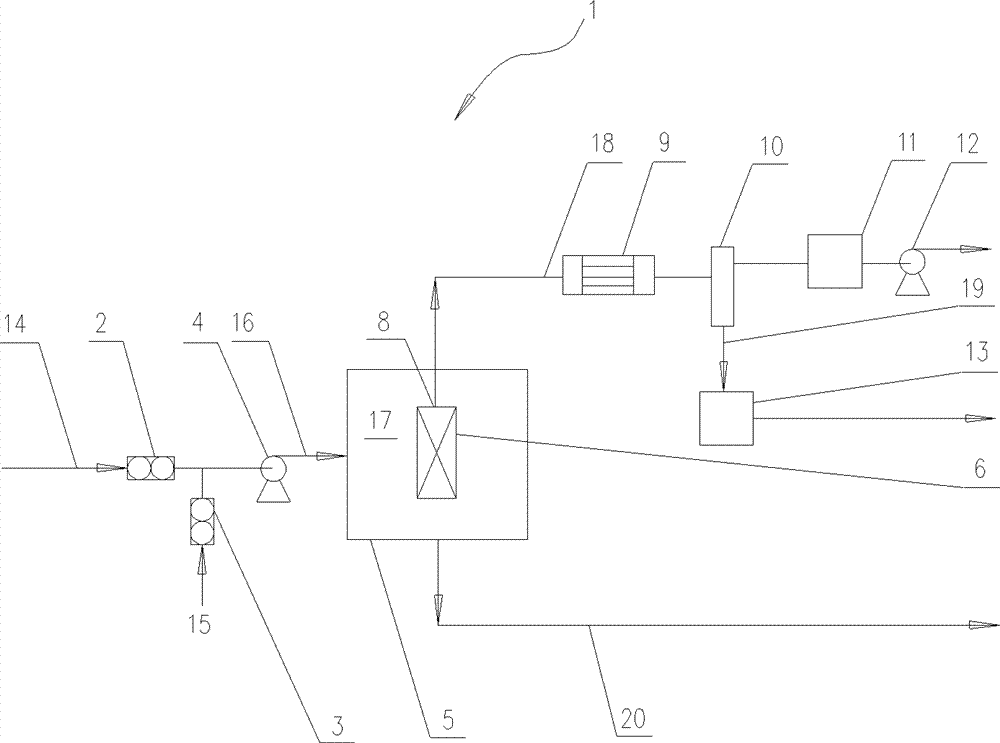

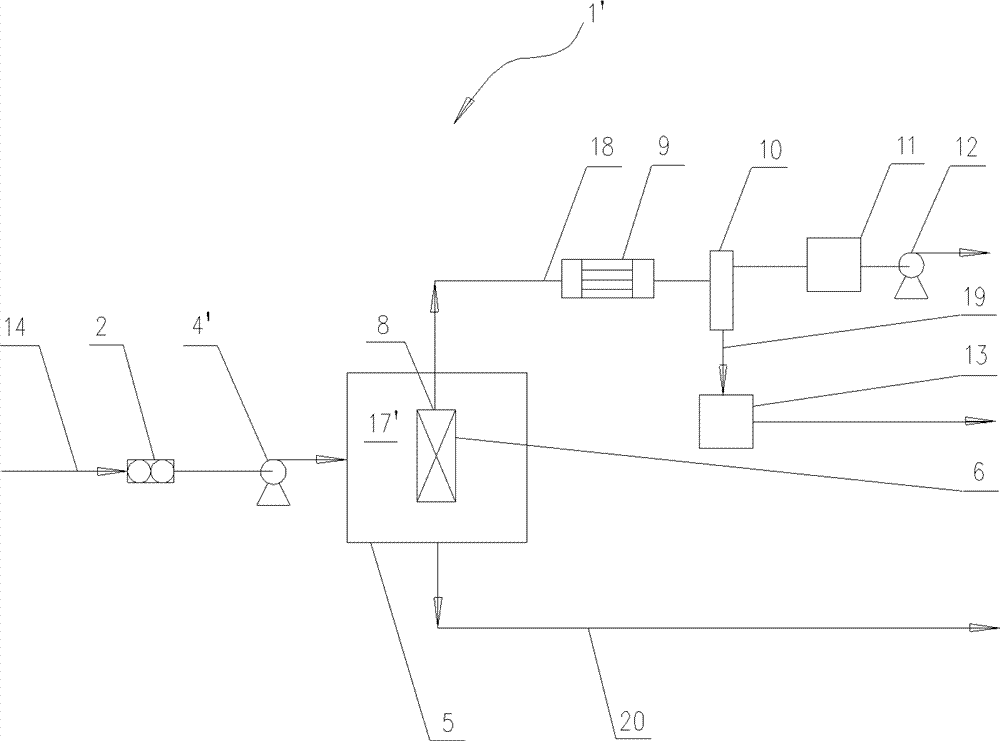

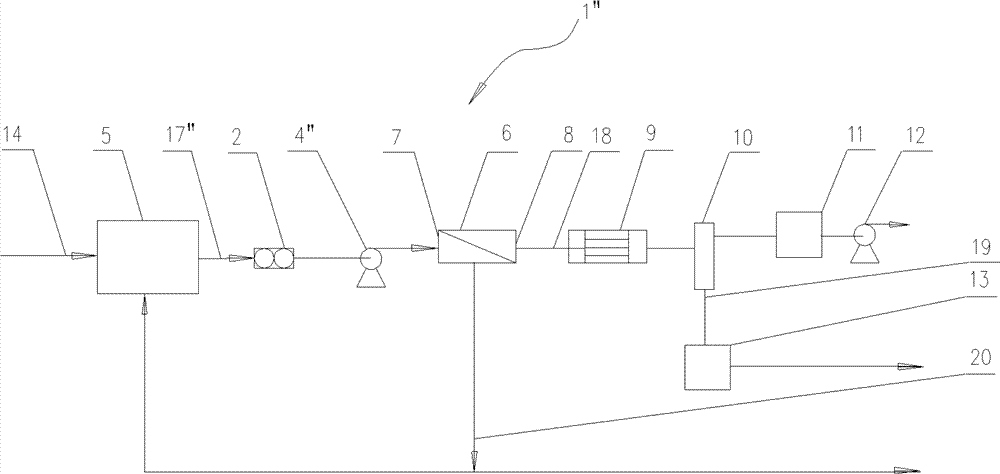

[0047] The reverse osmosis concentrated water of a petrochemical enterprise, the main water quality characteristics are: sewage pH 8, conductivity 25mS / cm, COD Cr 242mg / L, Ca 2+ 214mg / L, Mg 2+ 227mg / L, Na + 5078mg / L, Cl - 8407mg / L, dissolved silicon 36mg / L, NH 4 -N 2mg / L, turbidity 2NTU. For a schematic diagram of the process, see figure 1 .

[0048] The membrane distillation module used is a polytetrafluoroethylene plate-and-frame hydrophobic membrane module with a membrane pore size of 0.2 μm.

[0049] The process is as follows: First, the reverse osmosis concentrated water with a pH of 8 as influent water is dissolved into air with a gas-liquid volume ratio of 0.08:1 through an air-dissolving pump to form a gas-liquid mixture of influent water and air. The gas flow meter is used for metering; the gas-liquid mixture of the incoming water enters the heating water tank under the action of the dissolved air pump, and after being heated to a predetermined temperature of 7...

Embodiment 2

[0052] The main water quality characteristics of reverse osmosis concentrated water in a petrochemical enterprise are the same as in Example 1. For a schematic diagram of the process, see figure 1 .

[0053] The difference between the membrane distillation process of Example 2 and Example 1 is that the reverse osmosis concentrated water with a pH of 8 as the feed water is dissolved into the air with a gas-liquid volume ratio of 0.12:1 through the dissolved air pump to form a gas-liquid mixture of the feed water, and other membranes Distillation treatment conditions were the same as in Example 1.

[0054] The membrane distillation treatment effect of reverse osmosis concentrated water is shown in Table 2.

Embodiment 3

[0056] The main water quality characteristics of reverse osmosis concentrated water in a petrochemical enterprise are the same as in Example 1. For a schematic diagram of the process, see figure 1 .

[0057] The membrane distillation module used in Example 3 is a polypropylene hollow fiber curtain-type hydrophobic membrane module with a membrane pore size of 0.2 μm. Its membrane distillation process is different from Example 1 in that: the reverse osmosis concentrated water used as feed water is dissolved into air with a gas-liquid volume ratio of 0.12:1 through a dissolved air pump to form a feed water gas-liquid mixture, and the permeation side of the membrane distillation module (in the membrane hole of the hollow fiber membrane module) was vacuumed to form a negative pressure of -0.1MPa, and the other membrane distillation treatment conditions were the same as in Example 1.

[0058] The membrane distillation treatment effect of reverse osmosis concentrated water is shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com