Coarse cereal seeding machine for no-tillage seeding

The technology of no-tillage seeding and seeding machine is applied to the field of combined units for drought-resistant seeding in dry land, which can solve the problems of inability to directly cut off straw stubble, inability to sow small grass seeds, uneven surface, etc., so as to facilitate the absorption of soil nutrients and growth. , Improve the performance of the soil, the effect of large ground clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

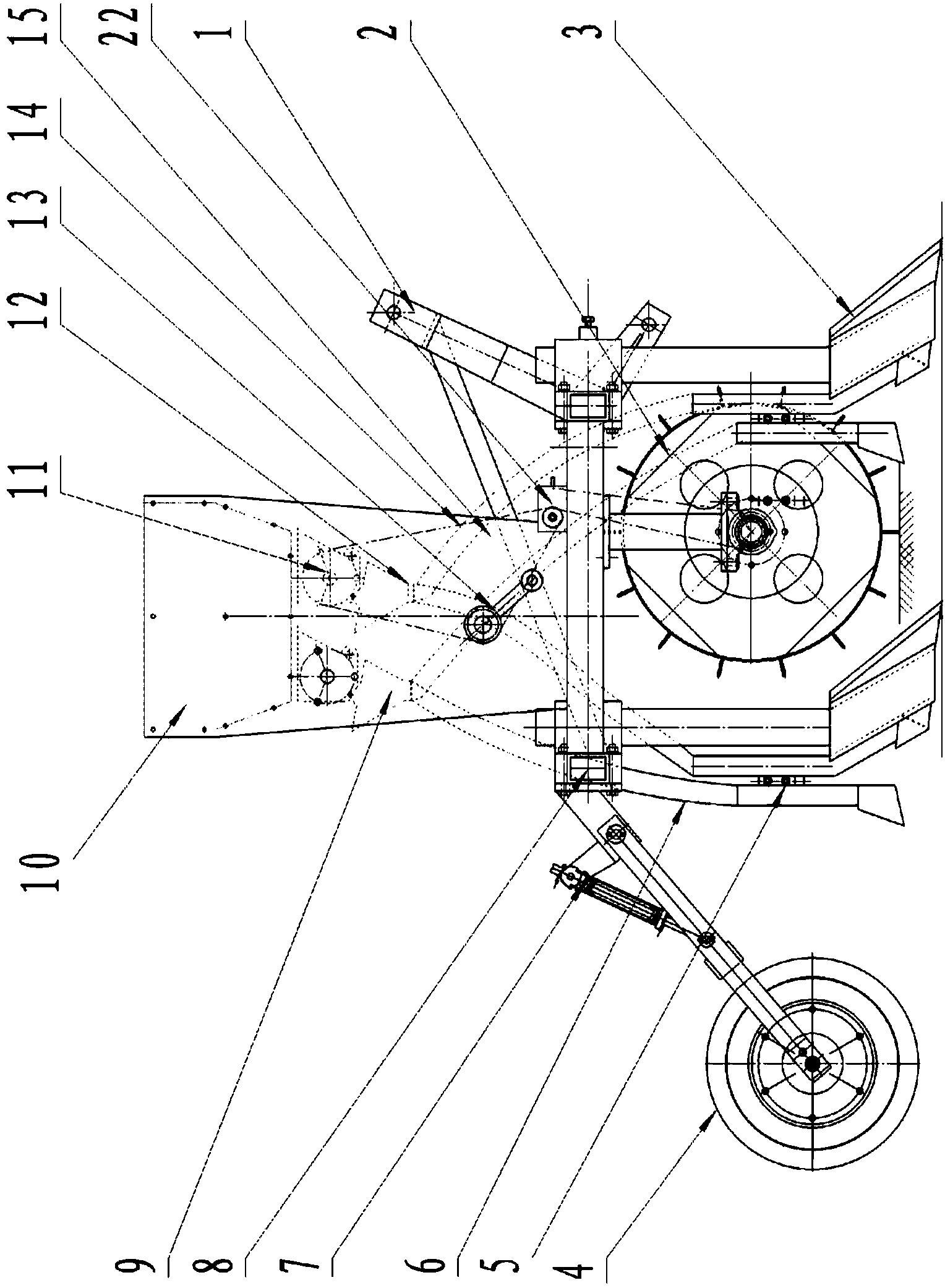

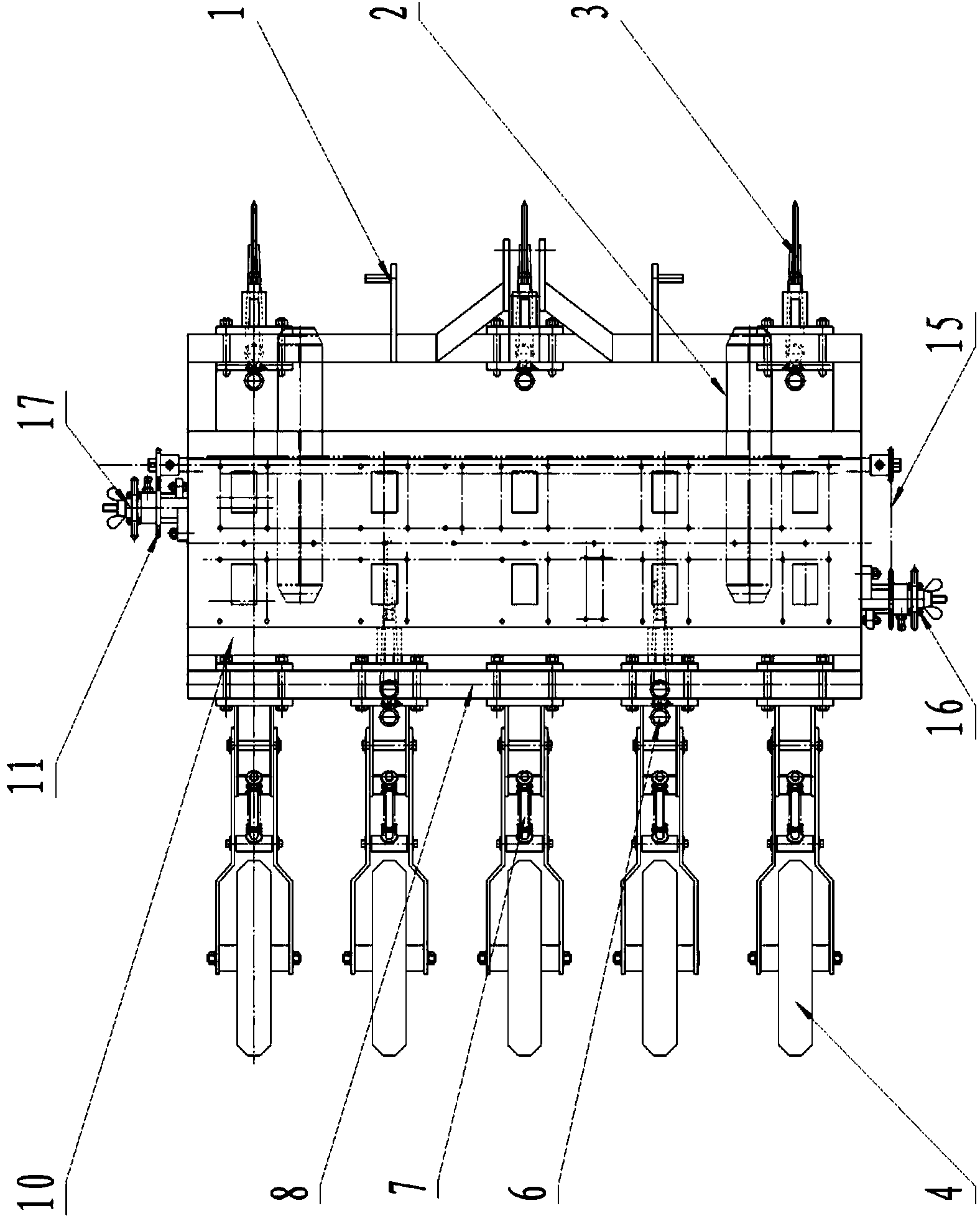

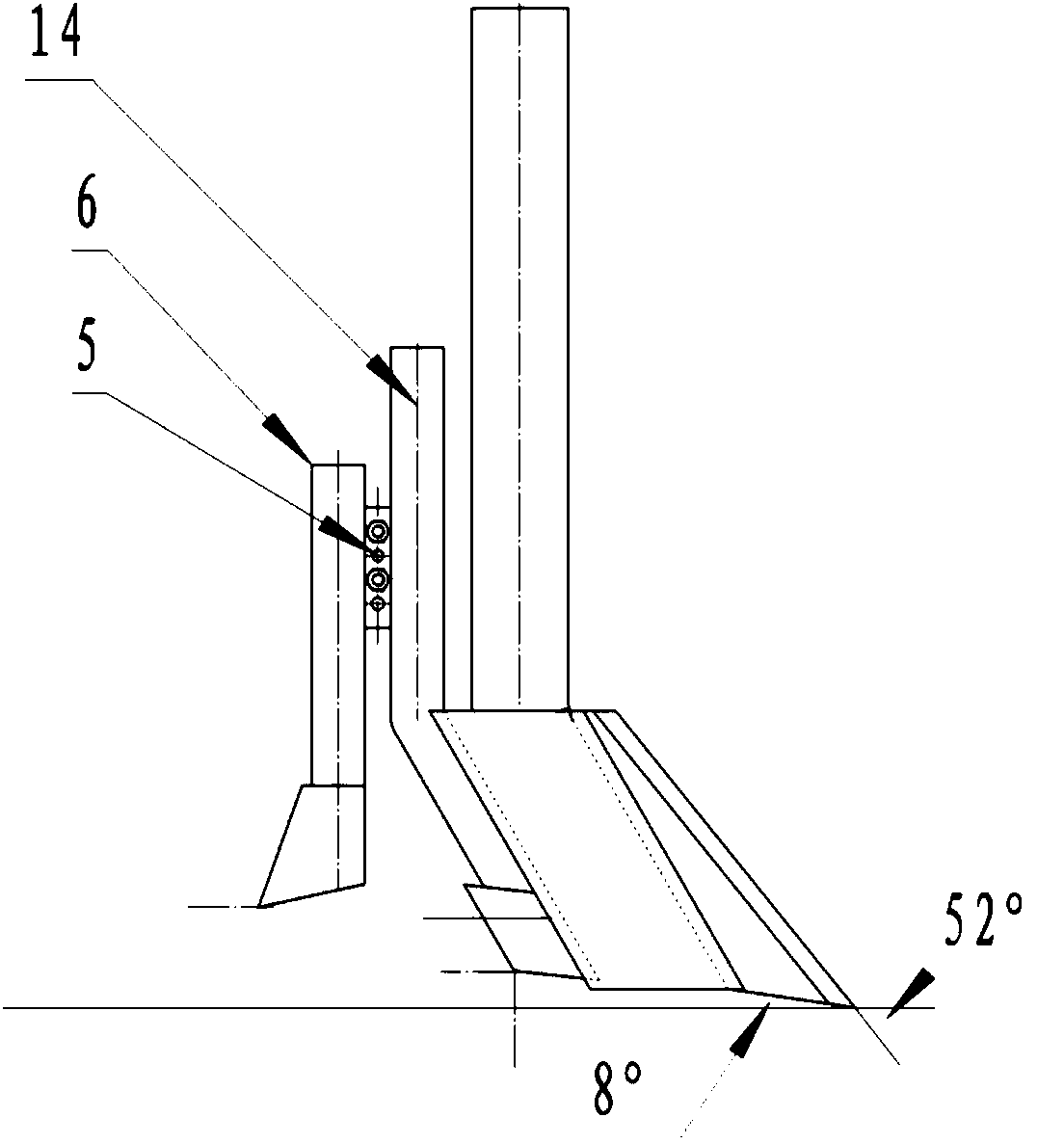

[0027] like figure 1 , 2 Shown, the miscellaneous grain seeder that is used for no-tillage sowing of the present invention is made up of suspension frame 1, ground wheel 2, broken stubble opener 3, suppressing mechanism 4, sowing depth adjustment plate 5, seed delivery pipe 6, suppressing wheel pressure Adjusting mechanism 7, frame 8, seed metering device 9, seed fertilizer box 10, fertilizer discharge sprocket 11, fertilizer discharge device 12, tension wheel 13, fertilizer delivery pipe 14, transmission system 15, seed discharge adjustment mechanism 16, Components such as fertilizer discharge adjustment mechanism 17, earth wheel sprocket 18, little earth wheel sprocket 19, large seed row 20, small seed row 21, tower wheel type gearbox 22 are formed.

[0028] The stubble breaking opener 3 is installed on the front and rear beams of the frame 8 through convex steel sleeves and bolts and nuts. Its function is to cut off the stubble and hard straw on the surface, and open a na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com