Electrochemical synchronous nitrogen and phosphorus removal apparatus and municipal sewage treatment method

A technology for synchronous denitrification and dephosphorization of urban sewage, which is applied in the field of electrochemical denitrification and dephosphorization devices, can solve the problems of complex structure of wastewater treatment system equipment, unsatisfactory removal rate of sewage indicators, and affecting the efficiency of electro-oxidation treatment. To achieve the effect of denitrification and phosphorus removal, saving manpower and improving oxidation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

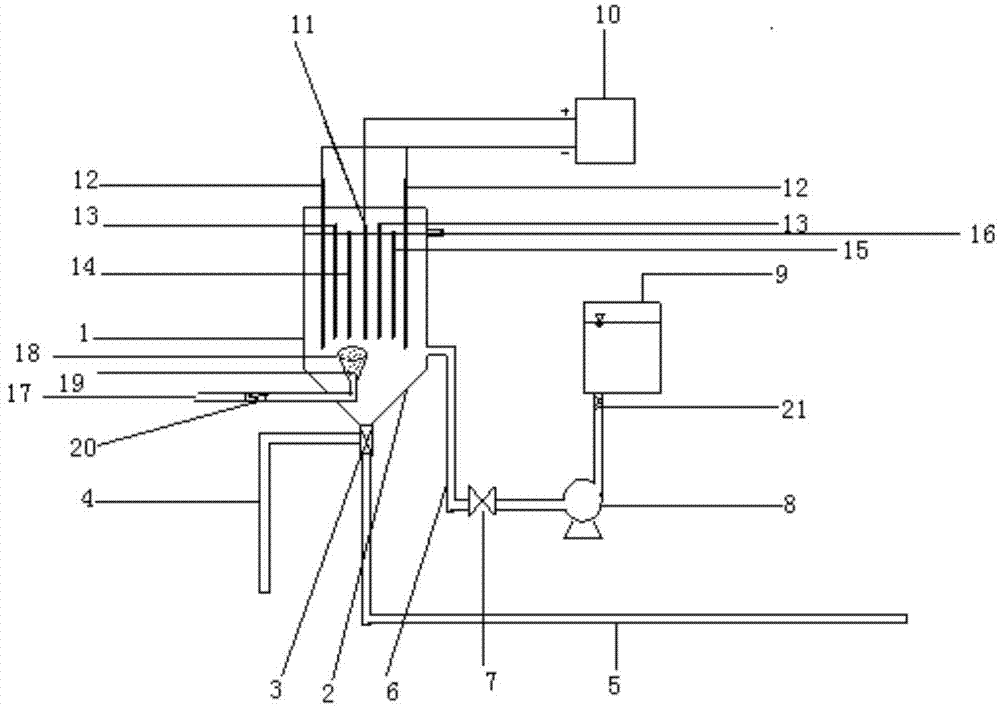

[0036] Example 1 A device for electrochemical simultaneous denitrification and dephosphorization of urban sewage

[0037] The device such as figure 2 As shown, the electrolytic cell 1 is provided with a conical bottom 2, which is convenient for flocculation and oxidation precipitation collection; the bottom of the conical bottom 2 is welded to the three-way valve 3, and the three-way valve 3 is respectively connected to the sewage pipe 4 and the water outlet pipe 5. ;

[0038] The side wall of the electrolytic cell 1 above the conical bottom 2 is provided with a water inlet, and the water inlet is fixedly welded with the water inlet pipe 6, and a flow meter 7 is arranged on the water inlet pipe 6, and the flow meter 7 passes through the outlet of the sewage pump 8 The water inlet pipe 6 is movably connected, and the inlet of the sewage pump 8 is movably connected with the water outlet valve 21 of the sewage tank 9 through a water pipe;

[0039] One side of the conical botto...

Embodiment 2

[0045] Open the outlet valve of the sewage tank, start the sewage pump, pump the sewage to be treated into the electrolytic cell, the sewage volume is 75% of the total capacity of the electrolytic cell, close the sewage pump and the sewage tank outlet valve after entering the water; turn on the DC power supply, adjust the current density 25mA / cm 2 , carry out electrochemical treatment for 15 minutes, at this time, reverse the electrode treatment for 5 minutes, pass compressed air into the aeration device during the whole process, and the aeration volume is 1.0L air / min.L sewage; then turn off the DC power supply and compressed air, and turn off the electrolytic cell Open the conical bottom three-way valve to the sewage pipe to collect nitrogen and phosphorus sediments; then open the conical bottom three-way valve of the electrolytic cell to the outlet pipe to collect the treated sewage for further solid-liquid separation, and the treated water can be discharged up to the standa...

Embodiment 3

[0052] Open the outlet valve of the sewage tank, start the sewage pump, pump the sewage to be treated into the electrolytic cell, the sewage volume is 75% of the total capacity of the electrolytic cell, close the sewage pump and the sewage tank outlet valve after entering the water; turn on the DC power supply, adjust the current density 15mA / cm 2 , carry out electrochemical treatment for 10 minutes, and supply compressed air to the aeration device during the whole process. Sewage pipes to collect nitrogen and phosphorus sediments; then open the three-way valve at the conical bottom of the electrolytic cell to the outlet pipe to collect the treated sewage for further solid-liquid separation, and the treated water can be discharged up to the standard.

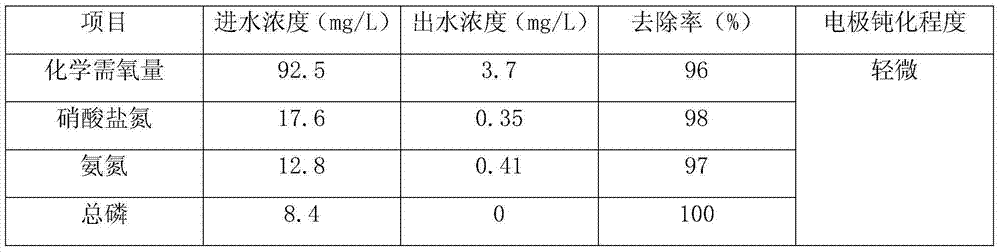

[0053] Treated by the above method, the treated water pollution indicators are shown in Table 3

[0054] table 3

[0055]

[0056] Note: The degree of electrode passivation from light to heavy is: slight, normal, relatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com