Modified reduced graphene oxide binder as well as preparation method and application thereof

A binder and graphene technology, applied in the direction of adhesives, inorganic adhesives, structural parts, etc., can solve the problems of high threshold for raw material production, environmental pollution, and large environmental pollution, and achieve good rate performance and cycle stability, The effect of good lithium ion conductivity and good electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

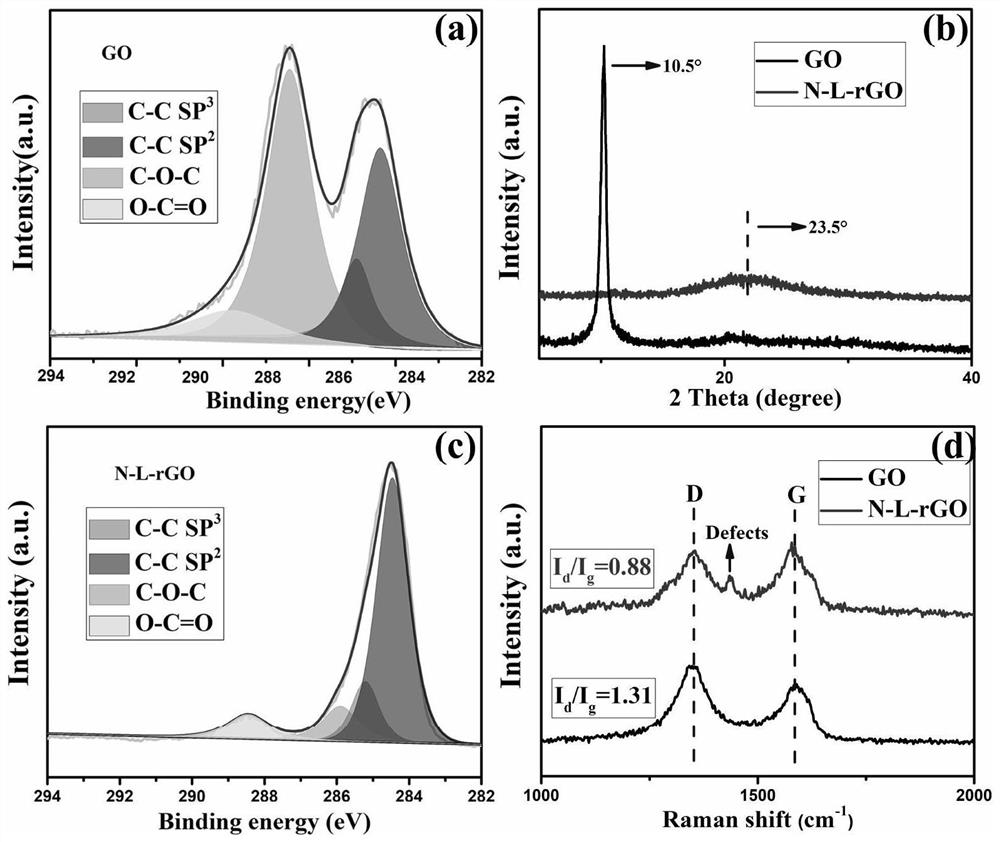

[0047] 100 mg of graphene oxide powder was uniformly dispersed in 100 mL of NMP solution, sonicated for 2 h, 1 g of ascorbyl palmitate powder was added to the solution and stirred for 4 h until uniform, then placed in a microwave reactor, reacted at a power of 600 W for 3 min, and then placed to room temperature, The product was collected after filtering the excess liquid with an organic filter, filtered again with water, and freeze-dried to obtain a powder sample.

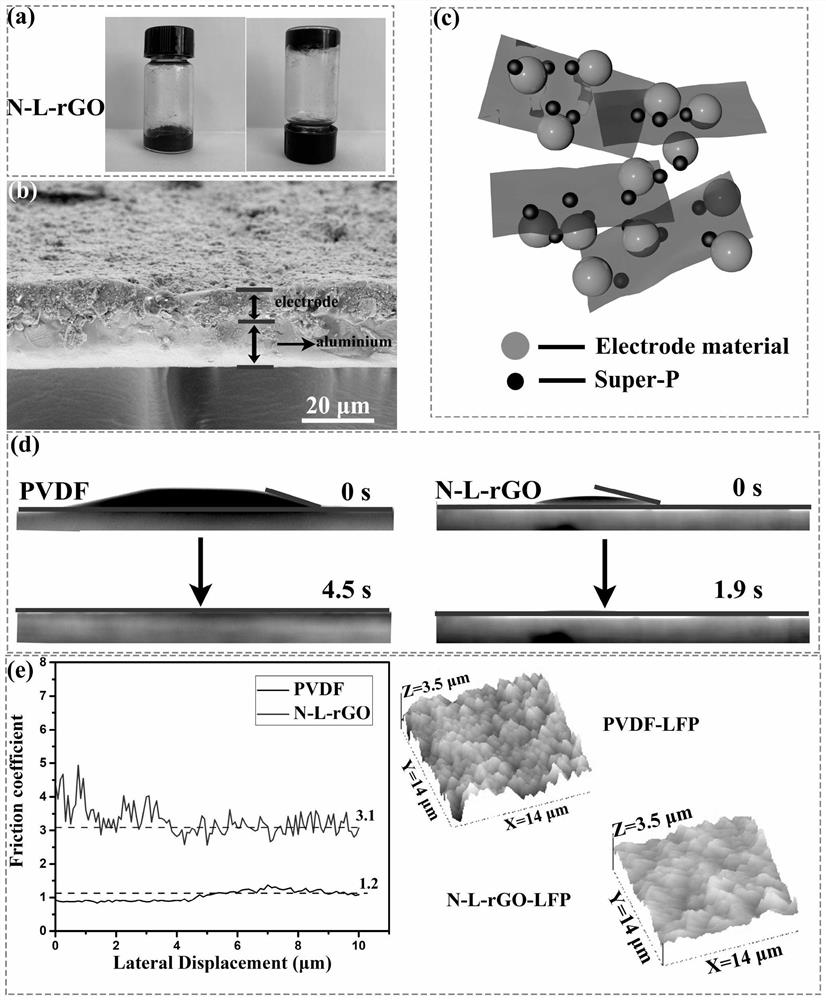

[0048] Electrode preparation: N-L-rGO and lithium iron phosphate were stirred in NMP solution for 3 hours at a mass ratio of 1:9, coated on aluminum foil, and vacuum dried at 120 °C for 12 hours to obtain the corresponding pole pieces.

[0049] Battery assembly: Cut the electrode into a 12mm diameter disc, and use the lithium sheet as the counter electrode, and assemble a CR2032 button battery in an argon atmosphere glove box. The electrolyte is 1M LiPF 6 (EC:DMC:EMC=1:1:1). like Figure 4 As shown, test rate p...

Embodiment 2

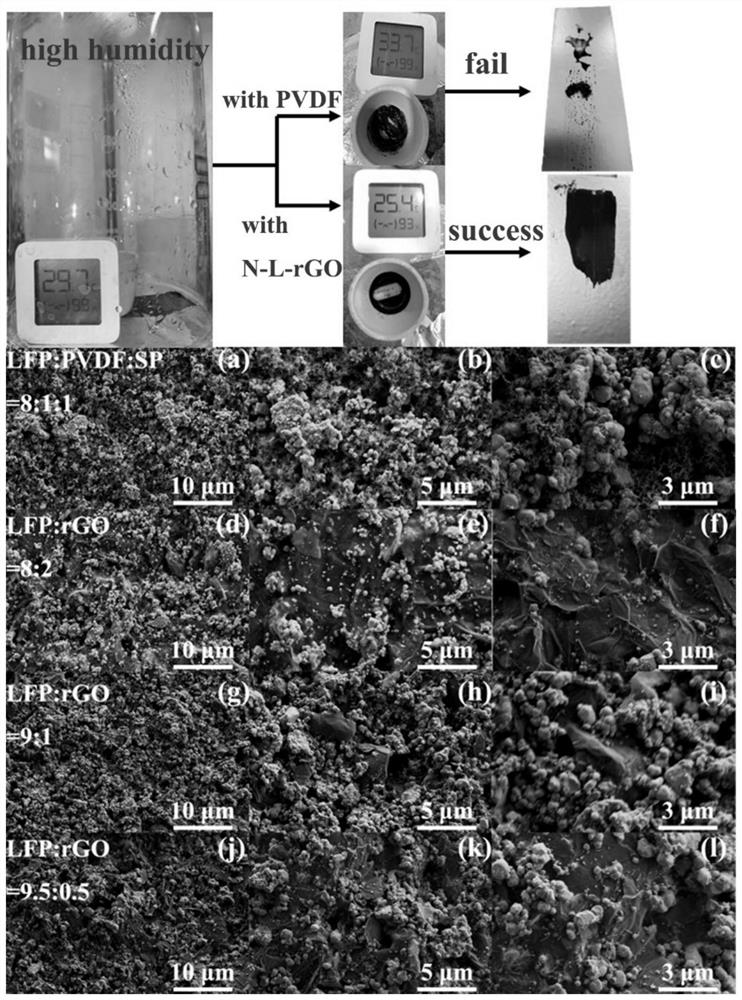

[0051] This example is basically the same as Example 1, except that the mass ratio of N-L-rGO to lithium iron phosphate is 2:8. Test rate performance at 0.2, 0.5, 1, 2, 5C, such as Image 6 .

Embodiment 3

[0053] This example is basically the same as Example 1, except that the mass ratio of N-L-rGO to lithium iron phosphate is 0.5:9.5. Test rate performance at 0.2, 0.5, 1, 2, 5C, such as Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com