Preparation method for fuel oil desulfuration adsorbent

An adsorbent and fuel oil technology, which is applied in chemical instruments and methods, hydrocarbon oil treatment, refined hydrocarbon oil, etc., can solve the problems of long reduction time, weak reduction of inert gas, and high reduction temperature, so as to improve the adsorption effect and reduce The effect of fast speed and short recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

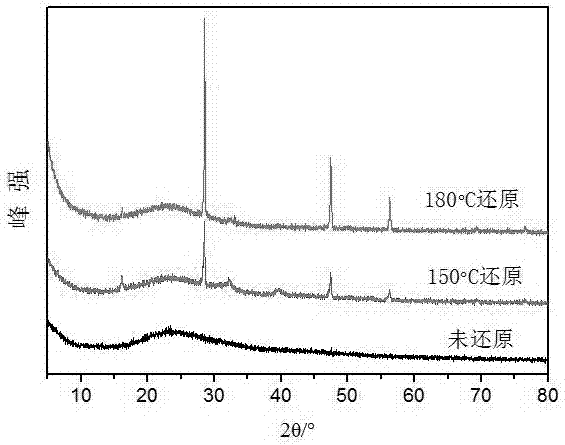

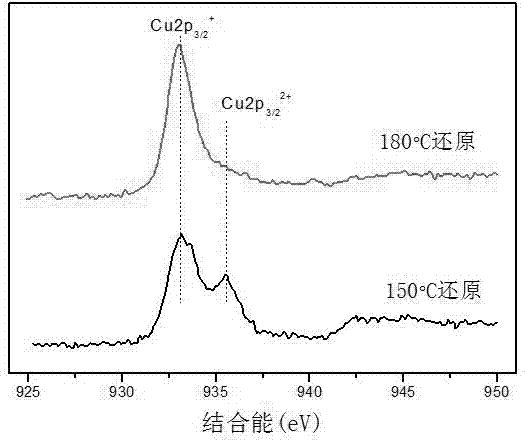

[0023] 1. Preparation of adsorbent: weigh 0.3g CuCl 2 2H 2 O and 1.0g of SBA-15 were placed in a 50mL beaker, then 10mL of 95% ethanol was added, and stirred at room temperature until the ethanol was completely volatilized to obtain a loaded CuCl 2 samples, labeled as CuCl 2 / SBA-15.

[0024] CuCl 2 / SBA-15 is placed in a quartz tube in a tube furnace, and a mixed gas composed of ethylene and nitrogen is introduced into the heating furnace, and the volume percentage of ethylene is 10%. Then set the temperature of the heating furnace to 120°C, and after reducing for 90 minutes, stop heating, wait for the furnace body to cool to room temperature under an inert atmosphere, stop ventilation, take out the quartz tube, and obtain an adsorbent loaded with cuprous chloride, which is marked as CuCl / SBA-15.

[0025] 2. Application: Dissolve benzothiophene in n-octane and dilute it to prepare simulated fuel oil with a sulfur content of 500ppm.

[0026] Take 10mL of simulated feedst...

Embodiment 2

[0028] 1. Preparation of adsorbent: weigh 0.3g CuCl 2 2H 2 O and 1.0g of SBA-15 were placed in a 50mL beaker, then 10mL of 95% ethanol was added, and stirred at room temperature until the ethanol was completely volatilized to obtain a loaded CuCl 2 samples, labeled as CuCl 2 / SBA-15.

[0029] CuCl 2 / SBA-15 is placed in the quartz tube of the tube furnace, and a mixed gas composed of ethylene and nitrogen is passed into the heating furnace, and the volume percentage of ethylene is 10%. Then set the temperature of the heating furnace to 180°C. After reducing for 90 minutes, stop heating. After the furnace body is cooled to room temperature under an inert atmosphere, stop ventilation, take out the quartz tube, and obtain an adsorbent loaded with cuprous chloride, which is marked as CuCl / SBA-15.

[0030] 2. Application: Dissolve benzothiophene in n-octane and dilute it to prepare simulated fuel oil with a sulfur content of 500ppm.

[0031] Take 10mL of simulated feedstock o...

Embodiment 3

[0033] 1. Preparation of adsorbent: weigh 0.3g CuCl 2 2H 2 O and 1.0g of SBA-15 were placed in a 50mL beaker, then 10mL of 95% ethanol was added, and stirred at room temperature until the ethanol was completely volatilized to obtain a loaded CuCl 2 samples, labeled as CuCl 2 / SBA-15.

[0034] CuCl 2 / SBA-15 is placed in the quartz tube of the tube furnace, and a mixed gas composed of ethylene and nitrogen is passed into the heating furnace, and the volume percentage of ethylene is 20%. Then set the temperature of the heating furnace to 180°C. After reducing for 90 minutes, stop heating. After the furnace body is cooled to room temperature under an inert atmosphere, stop ventilation, take out the quartz tube, and obtain an adsorbent loaded with cuprous chloride, which is marked as CuCl / SBA-15.

[0035] 2. Application: Dissolve benzothiophene in n-octane and dilute it to prepare simulated fuel oil with a sulfur content of 500ppm.

[0036] Take 10mL simulated oil and put it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com