A kind of graphene airgel and its preparation method and application

A graphene aerogel, graphene hydrogel technology, applied in the direction of graphene, electrical components, nano-carbon, etc., can solve the problems of deep processing and application of microcrystalline graphite, poor crystallization, fine embedded particle size, etc. The effect of comprehensive utilization, good integrity, and increased absorption strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

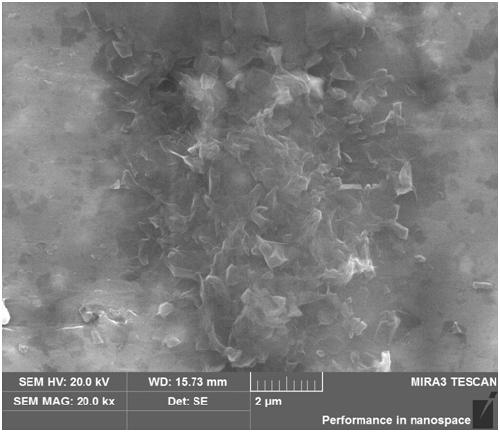

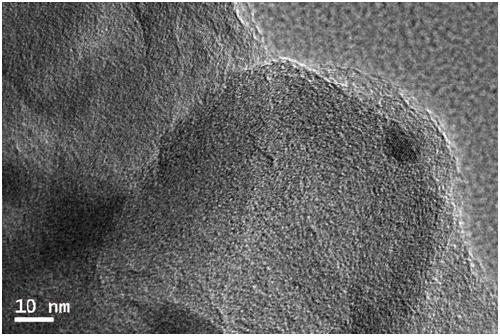

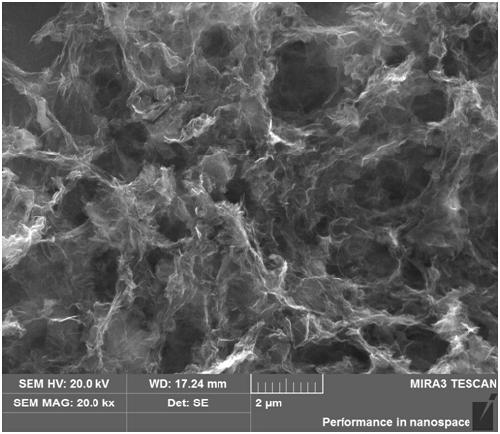

Image

Examples

reference example 1

[0075] Preparation of graphene oxide:

[0076] 1) Low-temperature pre-oxidation: Add 1.5g of microcrystalline graphite powder and 1.5g of sodium nitrate powder into 40mL of concentrated sulfuric acid, and stir and react in an ice-water bath at 0°C for 1 hour to obtain a low-temperature pre-oxidized graphite solution;

[0077] 2) Low-temperature oxidation: Divide 4.5g of potassium permanganate into 4 parts, and add it to the low-temperature pre-oxidized graphite solution obtained in step 1) every 30 minutes, and stir and react in an ice-water bath at 0°C for 2 hours to obtain a low-temperature oxidized graphite solution;

[0078] 3) Medium-temperature oxidation: Put the low-temperature oxidized graphite solution obtained in step 2) into a three-necked flask, stir and react in a medium-temperature water bath at 38°C for 20 hours, and then add 150 mL of deionized water dropwise under constant temperature conditions. The dropping speed of water is 0.3 mL / s. When the volume of add...

Embodiment 1

[0084] (1) Pre-reduction treatment: Add 30 mg of L-ascorbic acid to 10 mL of the graphene oxide solution (pH=5.5) obtained in Reference Example 1 with a mass concentration of 3 mg / mL and mix. The pH value after mixing is 5.6. No adjustment is required. 150W, frequency 40kHz, after ultrasonic dispersion for 5 minutes, pre-reduction treatment was carried out at 80°C for 30 minutes to obtain a semi-reduced graphene hydrogel;

[0085] (2) Final reduction treatment: Add 90 mg of L-ascorbic acid to the semi-reduced graphene hydrogel obtained in step (1), and perform ultrasonic treatment for 1 min at a power of 150 W and a frequency of 40 kHz, and then proceed at 80 ° C. Final reduction treatment for 30 minutes to obtain graphene hydrogel;

[0086] (3) Alkali soaking: Soak the graphene hydrogel obtained in step (2) in a 0.12mol / L potassium hydroxide solution for 3 hours, and replace it with a fresh 0.12mol / L potassium hydroxide solution every 1 hour to continue Soak and wash the hyd...

Embodiment 2

[0094] (1) Pre-reduction treatment: Add 60 mg of L-ascorbic acid to 10 mL of the graphene oxide solution (pH=5.5) obtained in Reference Example 1 with a mass concentration of 3 mg / mL and mix. The pH value after mixing is 5.7. No adjustment is required. 180W, frequency 40kHz, after ultrasonic dispersion for 5 minutes, pre-reduction treatment was carried out at 80°C for 60 minutes to obtain a semi-reduced graphene hydrogel;

[0095] (2) Final reduction treatment: Add 60 mg of L-ascorbic acid to the semi-reduced graphene hydrogel obtained in step (1), and perform ultrasonic treatment for 1 min at a power of 180 W and a frequency of 40 kHz, and then proceed at 80 ° C. Final reduction treatment for 60 minutes to obtain graphene hydrogel;

[0096] (3) Alkali soaking: Soak the graphene hydrogel obtained in step (2) in a 0.1mol / L sodium hydroxide solution for 4 hours, and replace it with a fresh 0.1mol / L sodium hydroxide solution every 1 hour to continue Soak and wash the hydrogel un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com