Fuel oil saving device of vehicle

A fuel and vehicle technology, applied in the direction of charging system, combustion engine, fuel air filter, etc., can solve the problems of carbon black emission, obvious carbon black, and greatly reduced efficiency, so as to reduce exhaust emission and avoid overoxygen Combustion, installation and debugging are simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

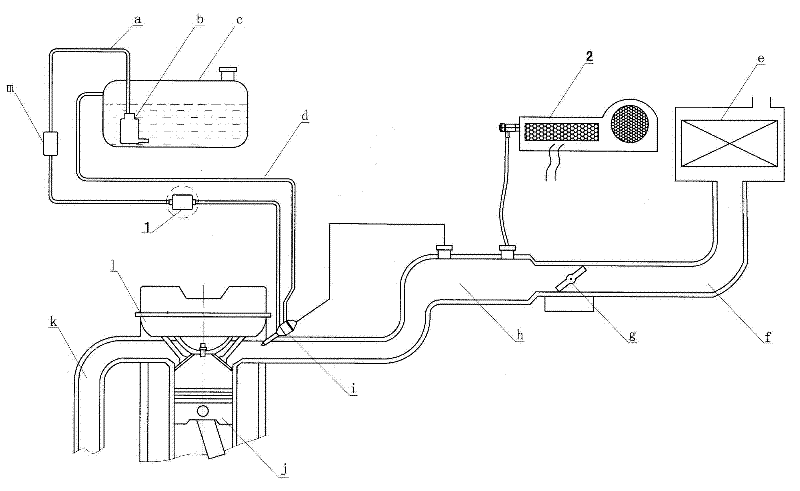

[0033] Depend on Figures 1 to 13 It can be seen that the vehicle fuel saving device of the present invention includes a fuel magnetization processor, which is characterized in that:

[0034] The fuel-saving device is composed of two groups, one group is the fuel magnetization processor 1 arranged on the engine oil inlet pipeline, and the other group is the oxygen increasing device 2 installed on the engine intake end or the vacuum tube, wherein:

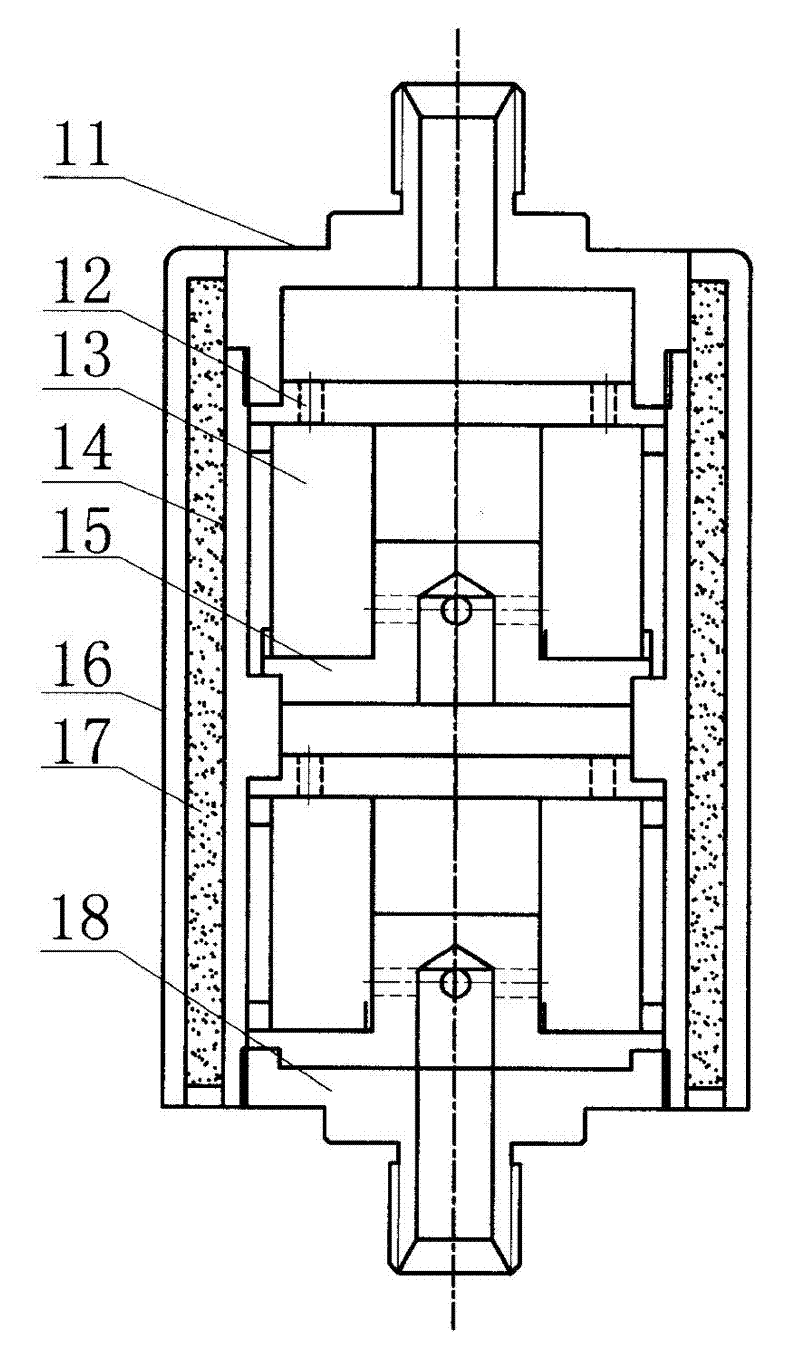

[0035] The described fuel magnetization processor includes two multi-gradient magnetization radiation areas composed of a main body 14, two stagnation areas and an output port, and the magnetic energy radiation area is composed of an upper support plate 12, a lower support plate 15 and a permanent Magnets 13 are formed, and two magnetic energy radiation areas are adjacent to each other, the entrance end of the first magnetic energy radiation area is the first stagnation area, and the second magnetic energy radiation area is the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com