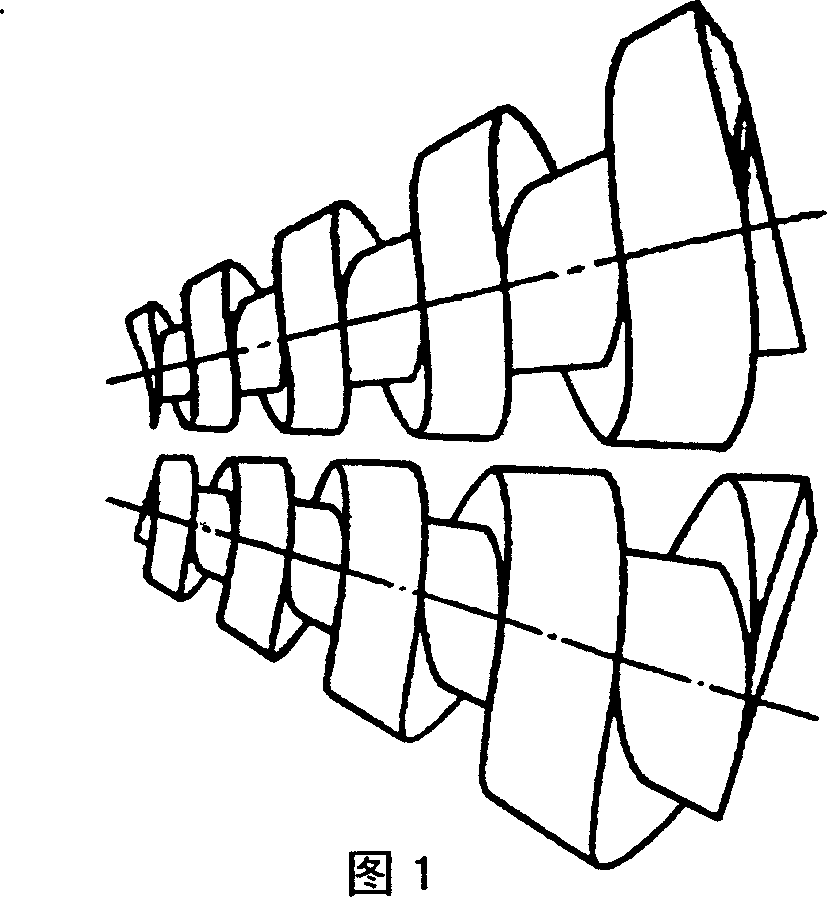

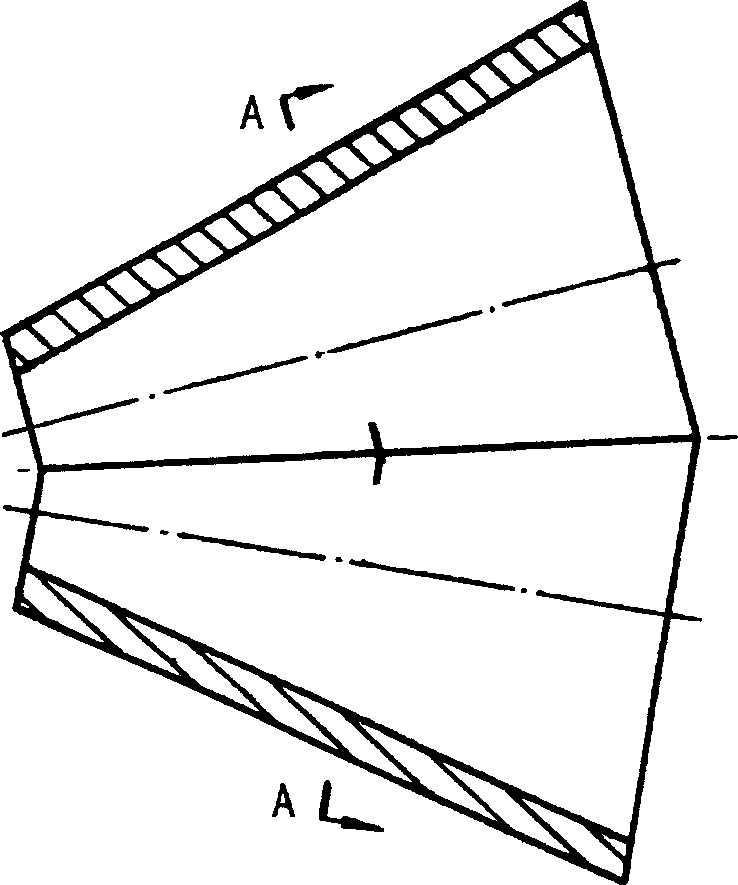

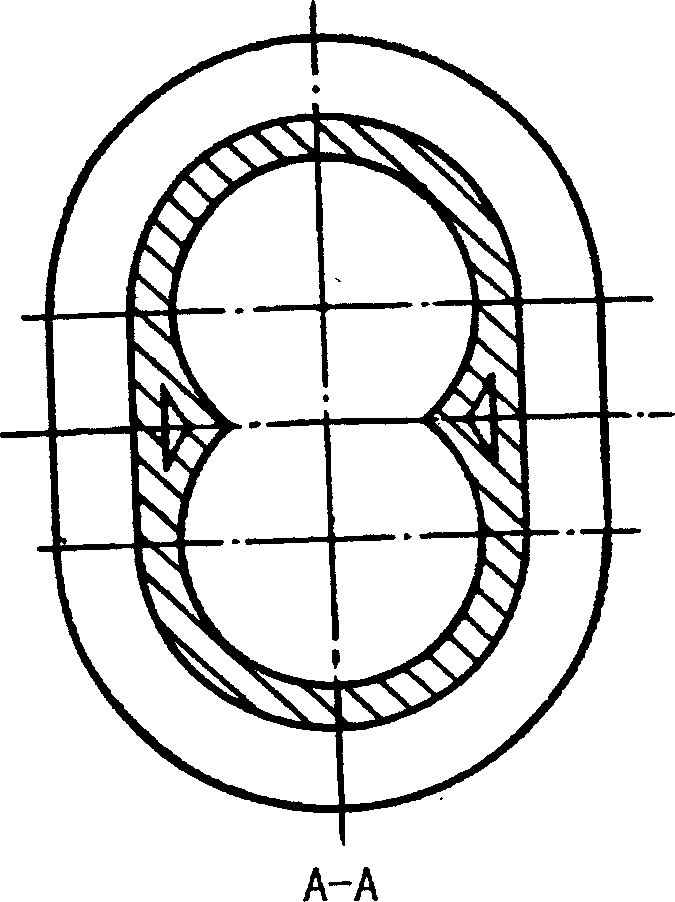

Capacity variable rotary internal combustion engine

A rotary engine and variable volume technology is applied in the field of power machines to achieve the effects of eliminating vibration and noise, reducing manufacturing costs and simplifying structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]The variable volume rotary engine of the present invention is a brand-new engine, and there are many technical categories involved in it. Including engine design and manufacturing and electrical control, basic materials and machinery manufacturing, etc. It needs the cooperation of many people to implement it. There are two specific implementation methods: one is to conduct trial production through relevant engine research institutes, and enter the factory for production after finalization. The other is to conduct trial production through a joint factory or company and university, and then transfer to production after finalizing the shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com