Recycling method of hydrogen peroxide oxidized tail gas

A technology for oxidizing tail gas and hydrogen peroxide, which is applied in chemical instruments and methods, separation methods, peroxides/peroxyhydrates/peroxyacids/superoxides/ozone oxides, etc., and can solve the problem of oxidation tail gas recovery and low utilization rate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

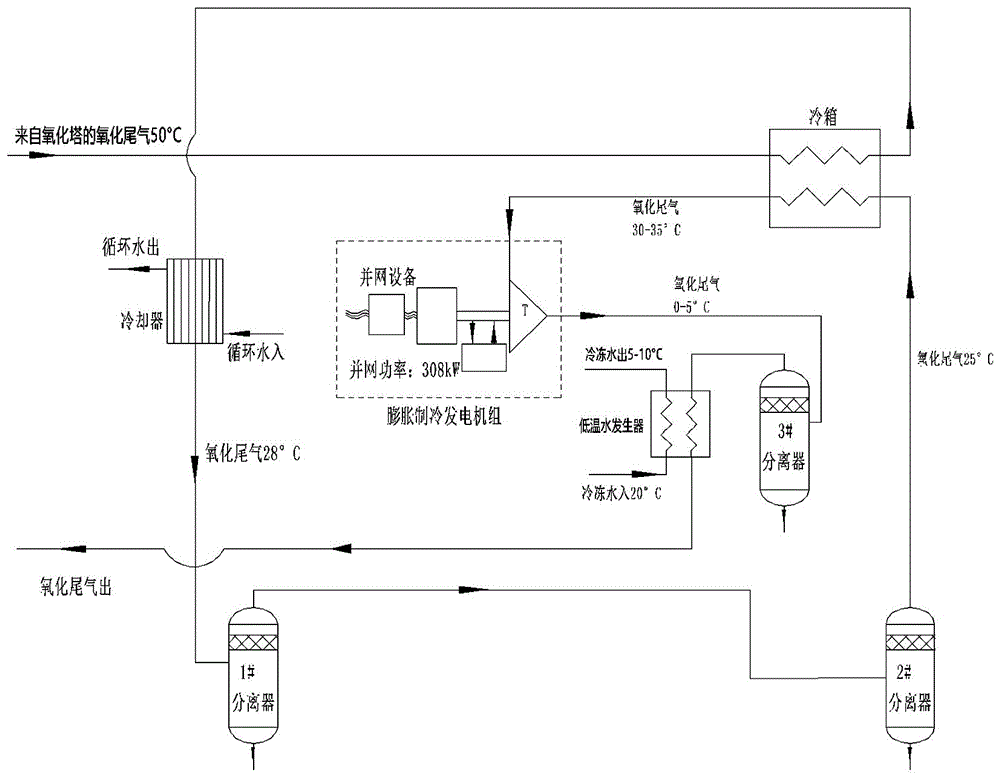

[0017] One, such as figure 1 As shown, a kind of device that realizes hydrogen peroxide oxidation tail gas recycling method provided by the present invention, it comprises the following components:

[0018] a. As the cold box of the primary cooler and the oxidation exhaust cooler of the secondary cooler, the inlet of the cooling end of the cold box is connected to the oxidation tower through a pipeline, and the outlet of the cooling section of the cold box is connected to the inlet of the oxidation exhaust cooler through a pipeline;

[0019] b. 1# separator and 2# separator, the inlet and outlet of 1# separator are respectively connected to the outlet of oxidation tail gas cooler and the inlet of 2# separator through pipes, and the outlet of 2# separator is connected to the cold box for heating through pipes end import;

[0020] c. The outlet of the heating end of the cold box is connected to the inlet of the expansion refrigeration generator set through pipes;

[0021] d. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com