Preparation method for Ti3SnC2 ceramic powder and prepared ceramic powder

A ceramic powder and powder technology, applied in the field of ceramic powder, can solve the problems of complex process and high equipment requirements, and achieve the effects of simple process, improved purity, and reduced sintering activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of Ti 3 SnC 2 The preparation method of the ceramic powder uses a mixture of Ti powder, Sn powder, Al powder and C powder as a raw material, activates the raw material by ball milling, conducts a self-propagating reaction, and then performs ball milling and pulverization.

[0021] Sn powder is used as a component in the MAX phase to form a solid solution. The addition of Al powder can fix the crystal lattice, refine the grain, replace part of Sn to form a solid solution, reduce the activation energy of sintering, make the product grain size small, high activity, easy to sinter, and excellent processing performance.

[0022] When the weight ratio of Ti powder: Sn powder: Al powder: C powder is 2.95-3.05:0.6-1:0.2-0.6:1.95-2.05, the raw materials can be fully reacted. Further, when the weight ratio of Ti powder: Sn powder: Al powder: C powder is 3: 0.6-1: 0.2-0.6: 2, the weight ratio of Ti powder: Sn powder: Al powder: C powder is better When the number ratio is...

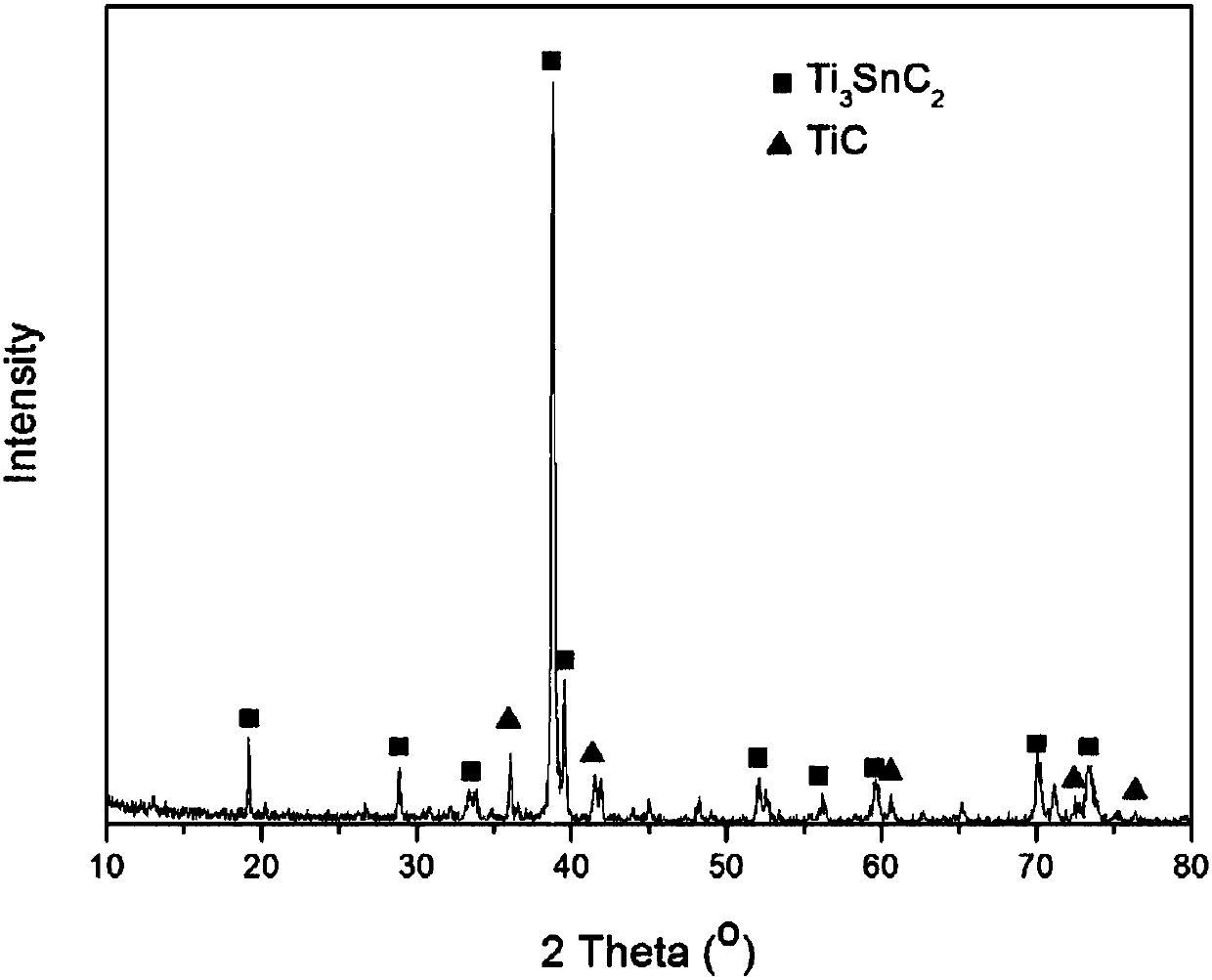

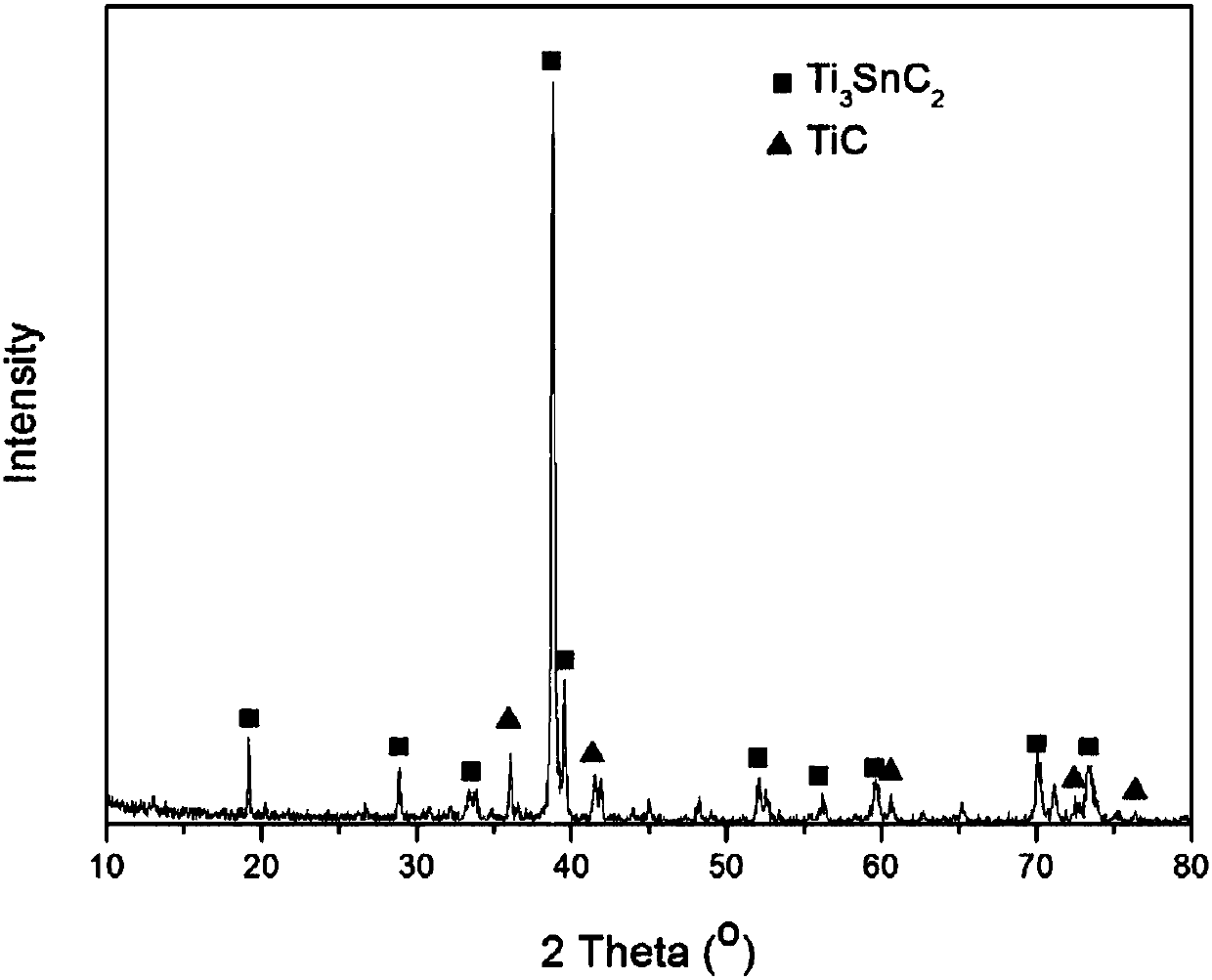

Embodiment 1

[0035] A kind of Ti 3 SnC 2 The preparation method of ceramic powder comprises:

[0036] Weigh 30g of Ti powder with a particle size of 400 mesh, 8g of Sn powder with a particle size of 400 mesh, 4g of Al powder with a particle size of 400 mesh, and 20g of C powder with a particle size of 400 mesh as raw materials. After mixing the raw materials, place them in a vacuum ball milling tank and pass in argon gas, use cemented carbide balls as grinding balls, and ball mill at a speed of 600r / min for 3 hours according to the ball-to-material ratio of 10:1 to obtain ball milling activated powder. Place the activated ball mill powder in a graphite crucible and place a tungsten wire coil on the surface, place the graphite crucible in a self-propagating high-temperature synthesis device to evacuate and fill it with argon, and energize the tungsten wire coil to ignite the ball mill activated powder. Self-propagating reaction, block product. Put the bulk product in a ball mill jar, use...

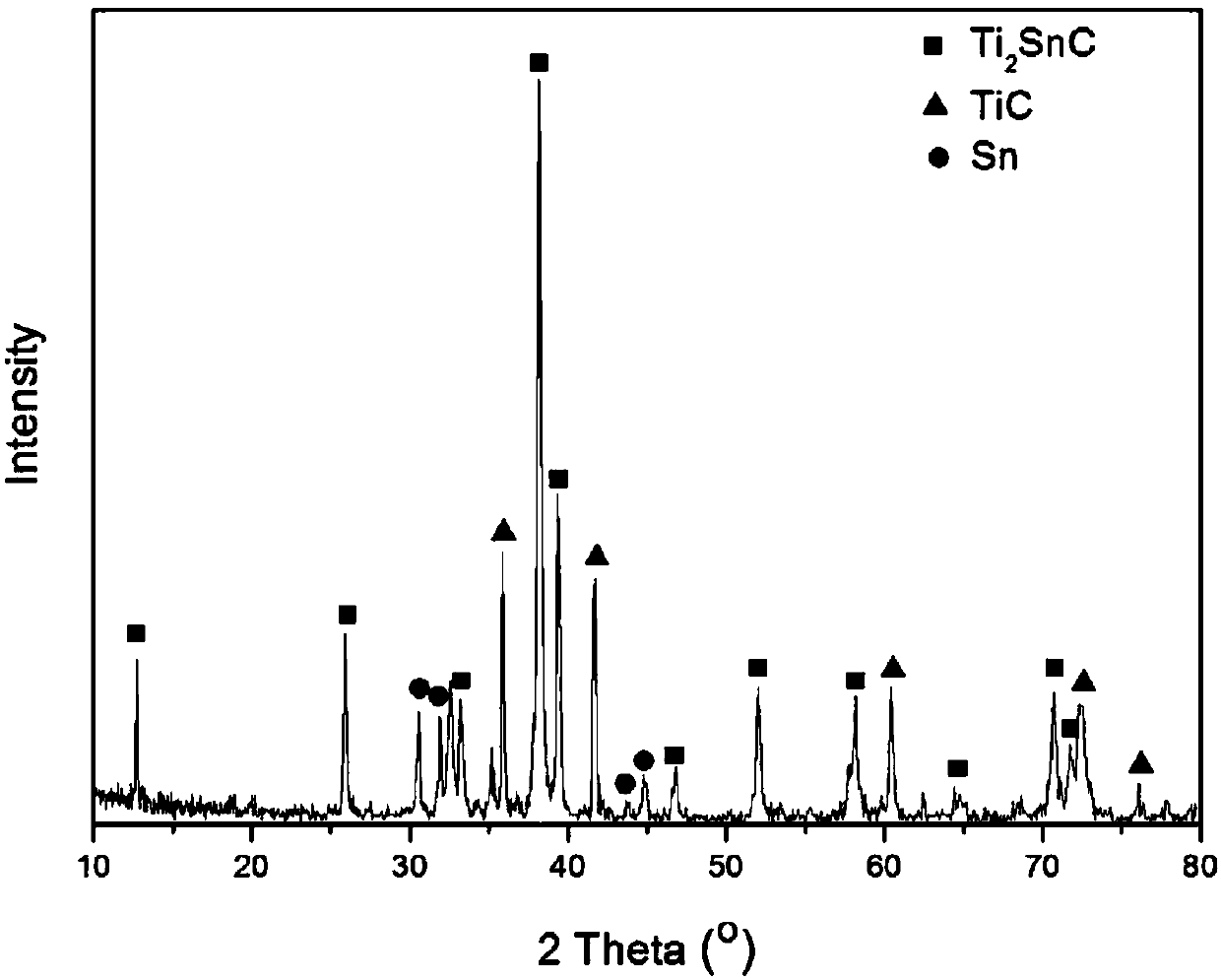

Embodiment 2

[0038] A kind of Ti 3 SnC 2 The preparation method of ceramic powder comprises:

[0039] Weigh 30g of Ti powder with a particle size of 400 mesh, 10g of Sn powder with a particle size of 400 mesh, 2g of Al powder with a particle size of 400 mesh, and 20g of C powder with a particle size of 400 mesh as raw materials. After mixing the raw materials, place them in a vacuum ball mill tank and pass in argon gas, use cemented carbide balls as grinding balls, and ball mill at a speed of 500r / min for 3 hours according to the ball-to-material ratio of 10:1 to obtain ball-milled activated powder. Place the activated ball mill powder in a graphite crucible and place a tungsten wire coil on the surface, place the graphite crucible in a self-propagating high-temperature synthesis device to evacuate and fill it with argon, and energize the tungsten wire coil to ignite the ball mill activated powder. Self-propagating reaction, block product. Put the bulk product in a ball mill jar, use ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com