Multi-stage composite rotational flow and turbulent flow sound wave super-strong viscosity reduction, paraffin control and oil increasing device

A turbulent sound wave, super technology, applied in the field of turbulent sound wave super viscosity reduction, wax prevention and oil increase device, multi-stage composite swirl, can solve the problem of easy blockage of oil pipes, achieve enhanced emulsification effect and improve flow performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

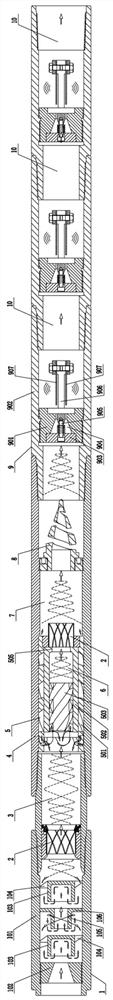

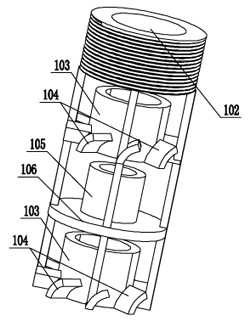

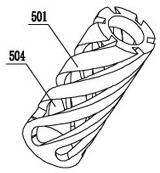

[0034] see Figure 1-6 , the present embodiment includes a tube shell 4, the front end of the tube shell 4 is provided with an oil inlet, and the rear end is provided with an oil outlet. The flow mechanism 5 includes an outer swirl sleeve 501 installed on the inner wall of the tube shell 4. An intermediate spacer 502 is fixedly installed on the inner wall of the outer swirl sleeve 501. The inner swirl column core 503 is installed inside the middle spacer 502. The swirl sleeve 501 and the inner swirl core 503 are respectively provided with an outer spiral oil passage and an inner spiral oil passage, and the middle spacer 502 is used to separate the inner spiral oil passage from the outer spiral oil passage , the tube shell 4 is located inside the oil outlet and is equipped with an atomizing nozzle 8; the tube shell 4 is equipped with a multi-stage turbulence mechanism 1 at the outer end of the oil inlet, and the multi-stage turbulence mechanism 1 and the layered swirl mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com