Carding machine cotton shaking plate covered with stainless steel plates

A technology of stainless steel plate and carding machine, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems of shaking cotton plate affecting product quality, etc., and achieve the effect of smooth and smooth overall surface, simple structure and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

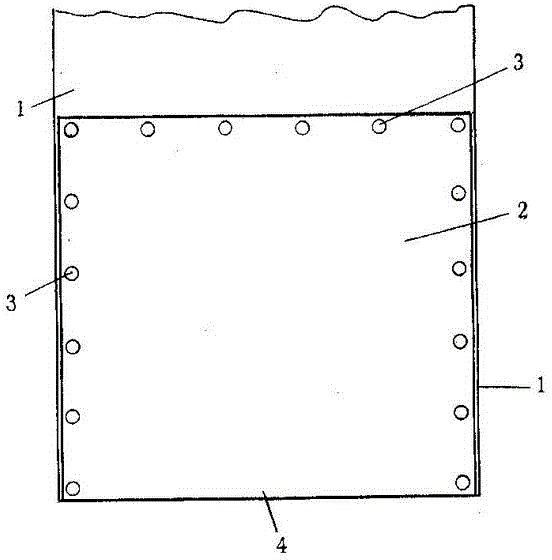

[0010] figure 1 Shown: the carding machine is covered with a layer of stainless steel plate 2 on the plate body 1 of the shaker plate. The covered stainless steel plate 2 is connected to the plate body 1 through peripheral rivets 3 . The connected rivets 3 are distributed on the upper side and both sides of the periphery where the stainless steel plate 2 and the plate body 1 are connected, and the lower periphery is a smooth edge 4 without rivets 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com