Dual-redundancy proportional pressure regulating mechanism

A proportional pressure regulation, double redundancy technology, applied in the direction of mechanical equipment, fluid flow, etc., can solve the problem of pressure regulating mechanism clogging and other problems, and achieve the effect of solving the problem of easy clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

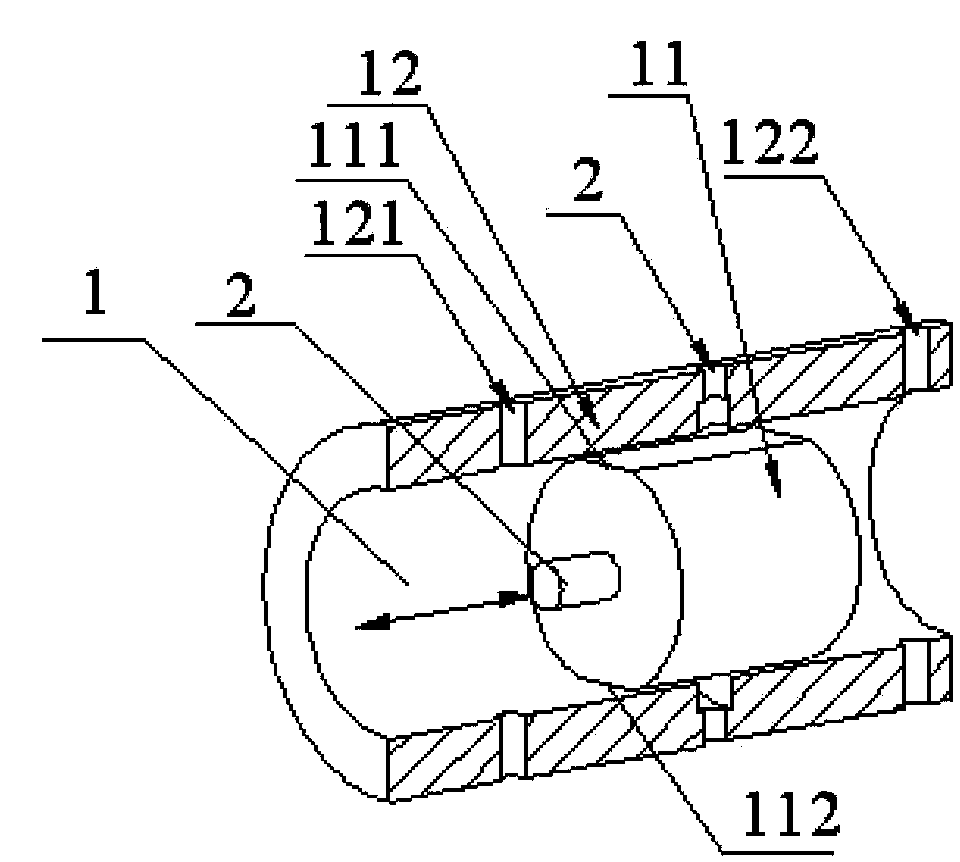

[0027] Embodiment 1 The double redundancy proportional pressure regulating mechanism of the present invention includes a fluid laminar flow double channel realization mechanism 1, a pressure taking point 2 and a pressure taking point position adjustment mechanism 3;

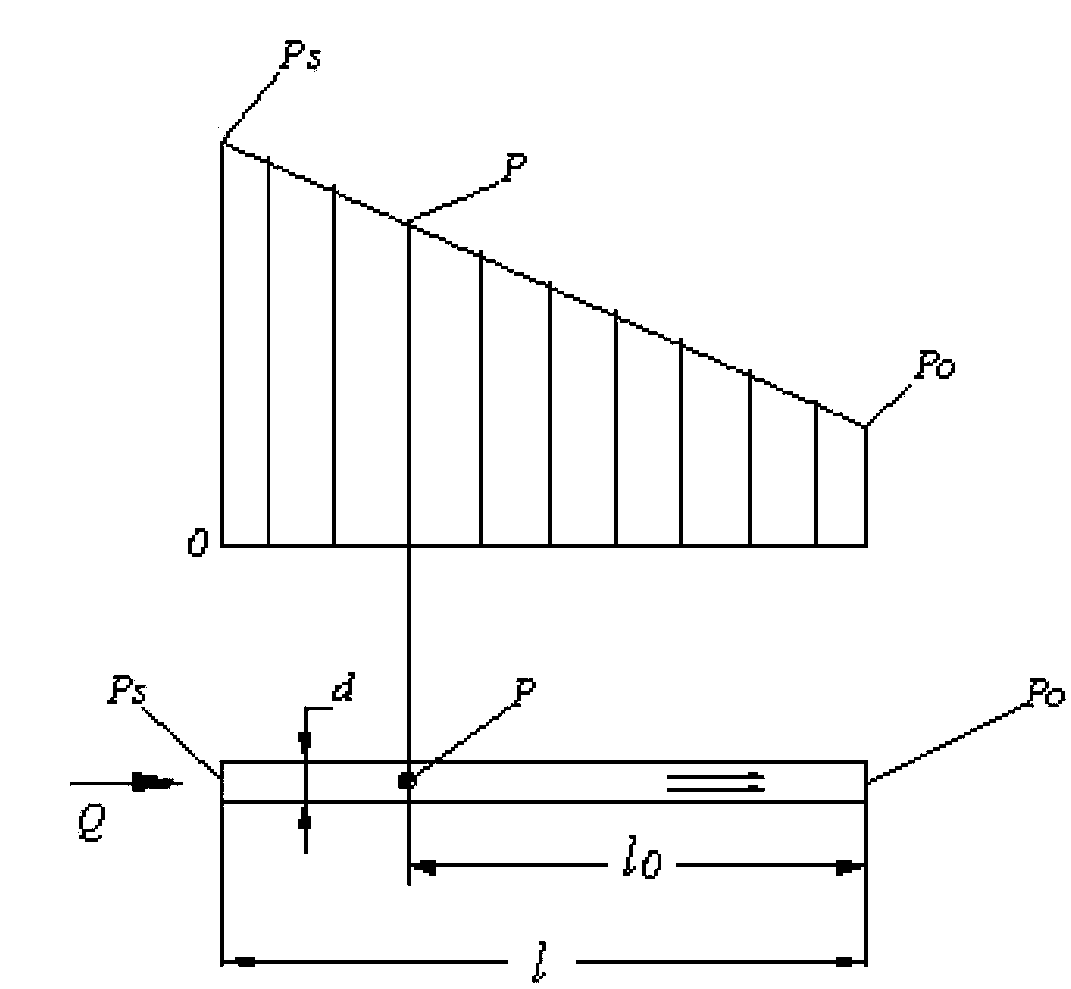

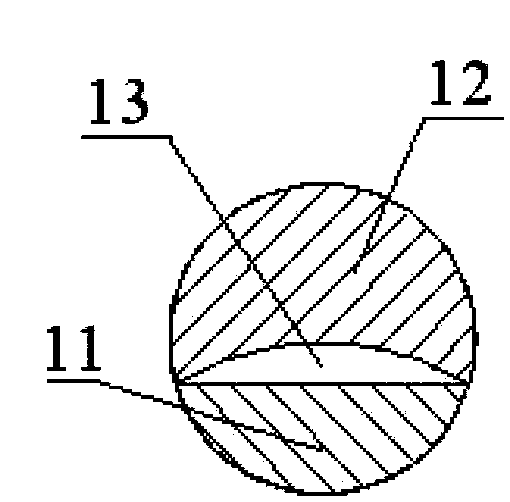

[0028] The fluid laminar double-channel realization mechanism 1 includes a valve core 11 and a valve sleeve 12; the side wall of the valve core 11 is axially provided with a first gap 111 and a second gap 112, the first gap 111, the The second gap 112 and the gap 13 formed by the inner wall of the valve sleeve 12 connect the oil inlet 121 and the oil outlet 122. The gap 13 is a laminar flow channel, and the fluid flow in the gap 13 presents a laminar flow state. , The pressure distribution of the oil inlet 121 and the oil outlet 122 presents a stable linear distribution;

[0029] The pressure point 2 is a pressure hole penetrating the valve sleeve, the pressure hole communicates with the gap, and the pressure point 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com