Modified cyclic phosphazene flame-retardant additive for lithium battery electrolyte and preparation method

A technology of flame retardant additive and cyclic phosphazene, which is applied in the field of modified cyclic phosphazene flame retardant additive for lithium battery electrolyte and its preparation, can solve the problems of high viscosity, reduction of electrolyte conductivity, deterioration of battery performance and the like, Achieve the effect of increasing the reduction potential, optimizing the interface SEI film, and improving the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

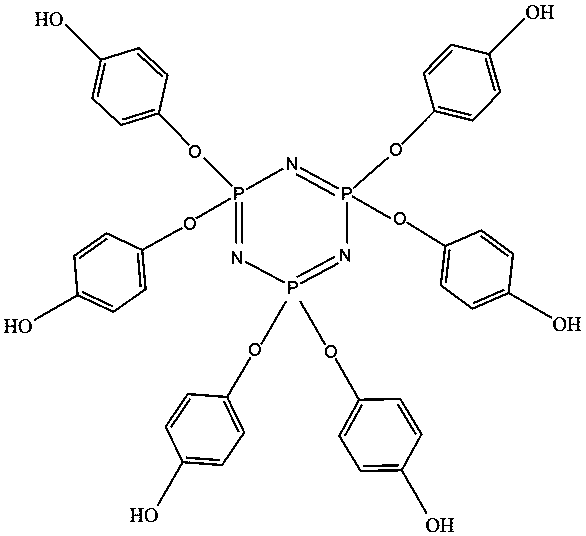

[0034] (1) Add hexachlorocyclotriphosphazene and hydroquinone into the solvent acetone, use benzyltriethylammonium chloride as a catalyst, react at 80°C for 3 hours, filter, wash and dry to obtain hexachlorocyclotriphosphazene and hydroquinone (4-hydroxyphenoxy)cyclotriphosphazene; the mass ratio of hexachlorocyclotriphosphazene, hydroquinone, acetone, and benzyltriethylammonium chloride is 1:2:80:0.03;

[0035] (2) Mix graphene nanosheets with oxalic acid, add them to a high-energy ball mill, mill them in a carbon dioxide atmosphere for 15 hours, and dry to remove oxalic acid after discharge to obtain carboxylated graphene; graphene nanosheets, oxalic acid The mass ratio of the high energy ball mill is 5:100; the rotating speed of the high energy ball mill is 240r / min, and every running 25min pauses for 5min;

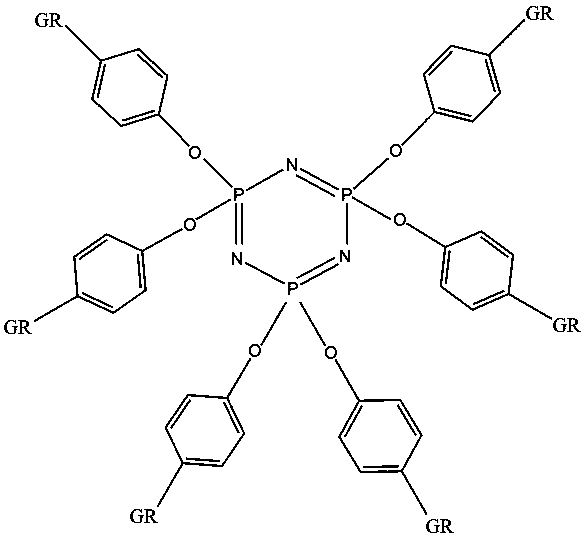

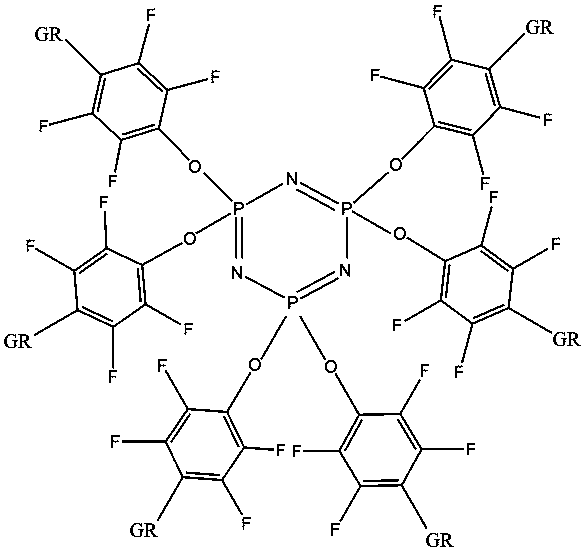

[0036] (3) Add carboxylated graphene into dimethyl sulfoxide, ultrasonically disperse for 20 minutes, then add hexa(4-hydroxyphenoxy)cyclotriphosphazene, use concentra...

Embodiment 2

[0039] (1) Add hexachlorocyclotriphosphazene and hydroquinone into the solvent acetone, use benzyltriethylammonium chloride as a catalyst, react at 70°C for 5 hours, filter, wash and dry to obtain hexachlorocyclotriphosphazene and hydroquinone (4-hydroxyphenoxy)cyclotriphosphazene; the mass ratio of hexachlorocyclotriphosphazene, hydroquinone, acetone, and benzyltriethylammonium chloride is 1:2:80:0.03;

[0040] (2) Mix graphene nanosheets with oxalic acid, add them to a high-energy ball mill, mill them in a carbon dioxide atmosphere for 10 hours, and dry them after discharging to remove oxalic acid to obtain carboxylated graphene; graphene nanosheets, oxalic acid The mass ratio is 3:100; the rotating speed of high-energy ball mill is 240r / min, every running 20min pauses 5min;

[0041](3) Add carboxylated graphene to dimethyl sulfoxide, ultrasonically disperse for 40 minutes, then add hexa(4-hydroxyphenoxy)cyclotriphosphazene, use concentrated sulfuric acid as catalyst, react ...

Embodiment 3

[0044] (1) Add hexachlorocyclotriphosphazene and hydroquinone into the solvent acetone, use benzyltriethylammonium chloride as a catalyst, react at 75°C for 4 hours, filter, wash and dry to obtain hexachlorocyclotriphosphazene and hydroquinone (4-hydroxyphenoxy)cyclotriphosphazene; the mass ratio of hexachlorocyclotriphosphazene, hydroquinone, acetone, and benzyltriethylammonium chloride is 1:2:80:0.03;

[0045] (2) Mix graphene nanosheets with oxalic acid, add them to a high-energy ball mill, mill in a carbon dioxide atmosphere for 12 hours, and dry to remove oxalic acid after discharge to obtain carboxylated graphene; graphene nanosheets, oxalic acid The mass ratio of the high-energy ball mill is 4:100; the rotating speed of the high-energy ball mill is 240r / min, and every running 22min pauses for 5min;

[0046] (3) Add carboxylated graphene to dimethyl sulfoxide, ultrasonically disperse for 30 minutes, then add hexa(4-hydroxyphenoxy)cyclotriphosphazene, use concentrated sul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com