Non-aqueous electrolyte, preparation method of non-aqueous electrolyte and lithium ion secondary battery containing non-aqueous electrolyte

A non-aqueous electrolyte and electrolyte technology, applied in the direction of secondary batteries, circuits, electrical components, etc., can solve the problems of no commercial value, reduced battery life, high manufacturing costs, etc., to optimize the solid electrolyte interface film, flammability The effect of reducing and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the electrolyte solution provided by the present invention is to mix the fluoride and the non-aqueous solvent in a certain proportion in a dry environment, then add the lithium salt into the above-mentioned non-aqueous solvent, heat and stir at 30-80°C to make The lithium salt is fully dissolved to make an electrolyte.

[0021] The lithium ion secondary battery provided by the present invention comprises a positive electrode, a negative electrode, a separator paper and an electrolyte, wherein the above-mentioned non-aqueous electrolyte is used as the electrolyte.

[0022] The positive electrode includes an active material, a conductive agent, a binder and a current collector. The positive active material includes LiCoO 2 , LiMnO 2 , LiNiO 2 、LiNi 1 / 3 mn 1 / 3 co 1 / 3 o 2 and lithium metal phosphate salts with an olivine structure: Li 1+a L b PO 4 ; In the formula, -0.1≤a≤0.2, 0.9≤b≤1.1, L is at least one of iron, aluminum, manganese, cob...

Embodiment 1

[0032] Choose a fluoride solvent with the following structure:

[0033] Compound A;

[0034] (1) Preparation of electrolyte

[0035] Prepare the electrolyte solution in an argon-filled glove box (H2O6 , making the concentration of LiPF6 reach 1mol / L.

[0036] (2) Preparation of positive electrode

[0037] Fully stir and mix LiFePO4, carbon black and polyvinylidene fluoride (PVDF) at a weight ratio of 94:3:3, and mix and stir the obtained mixture with N-methylpyrrolidone (NMP) at a weight ratio of 1:1.2 The positive electrode slurry was uniformly prepared. Use a coating machine to evenly coat the obtained positive electrode slurry on the aluminum foil current collector, dry at 130°C, cut and calender to obtain the positive electrode sheet, which contains 6 grams of LiFePO 4 .

[0038] (3) Preparation of negative electrode

[0039] Artificial graphite, SBR and CMC were mixed in a weight ratio of 96:2:2, and the obtained mixture was mixed with deionized water in a weight ...

Embodiment 2~5

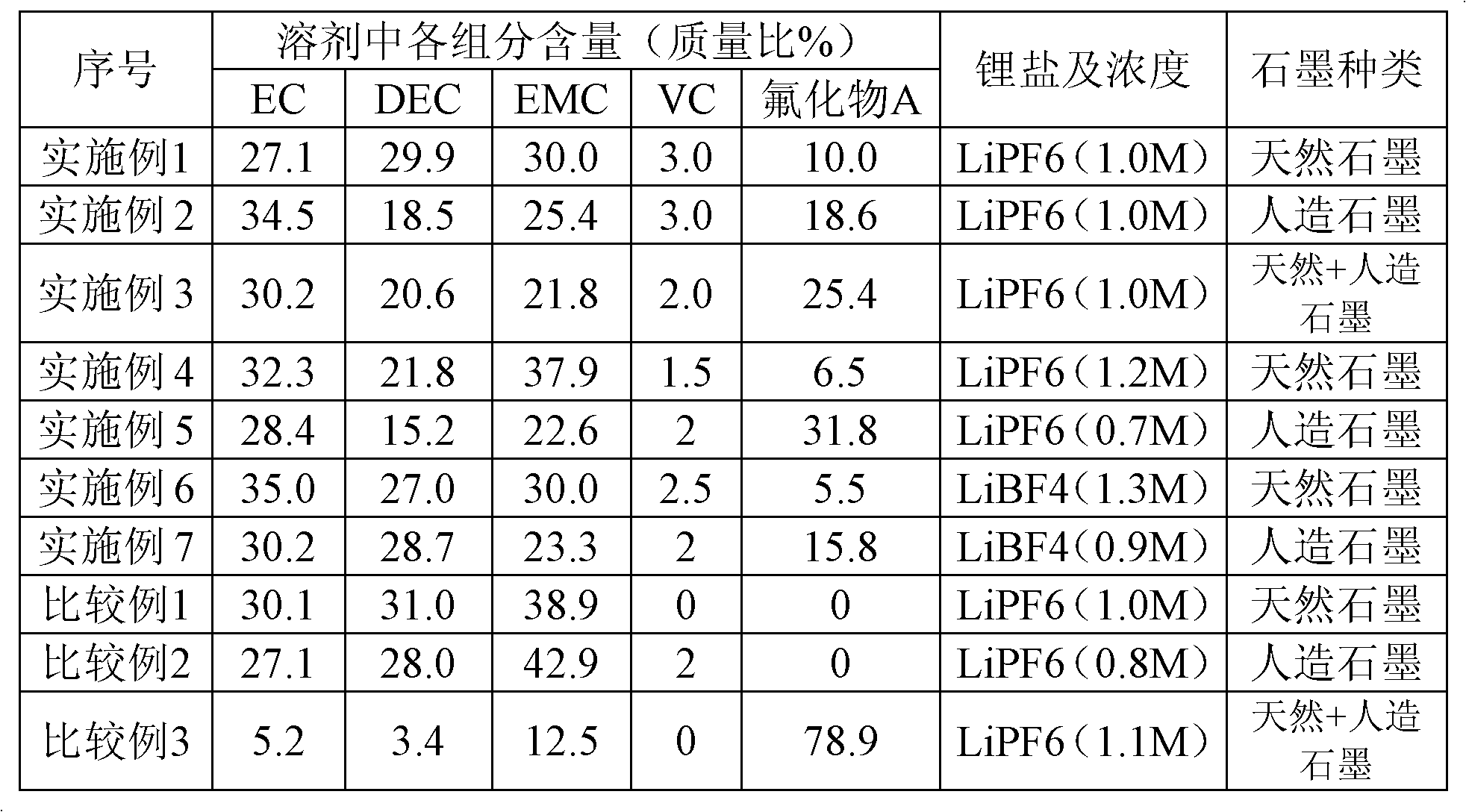

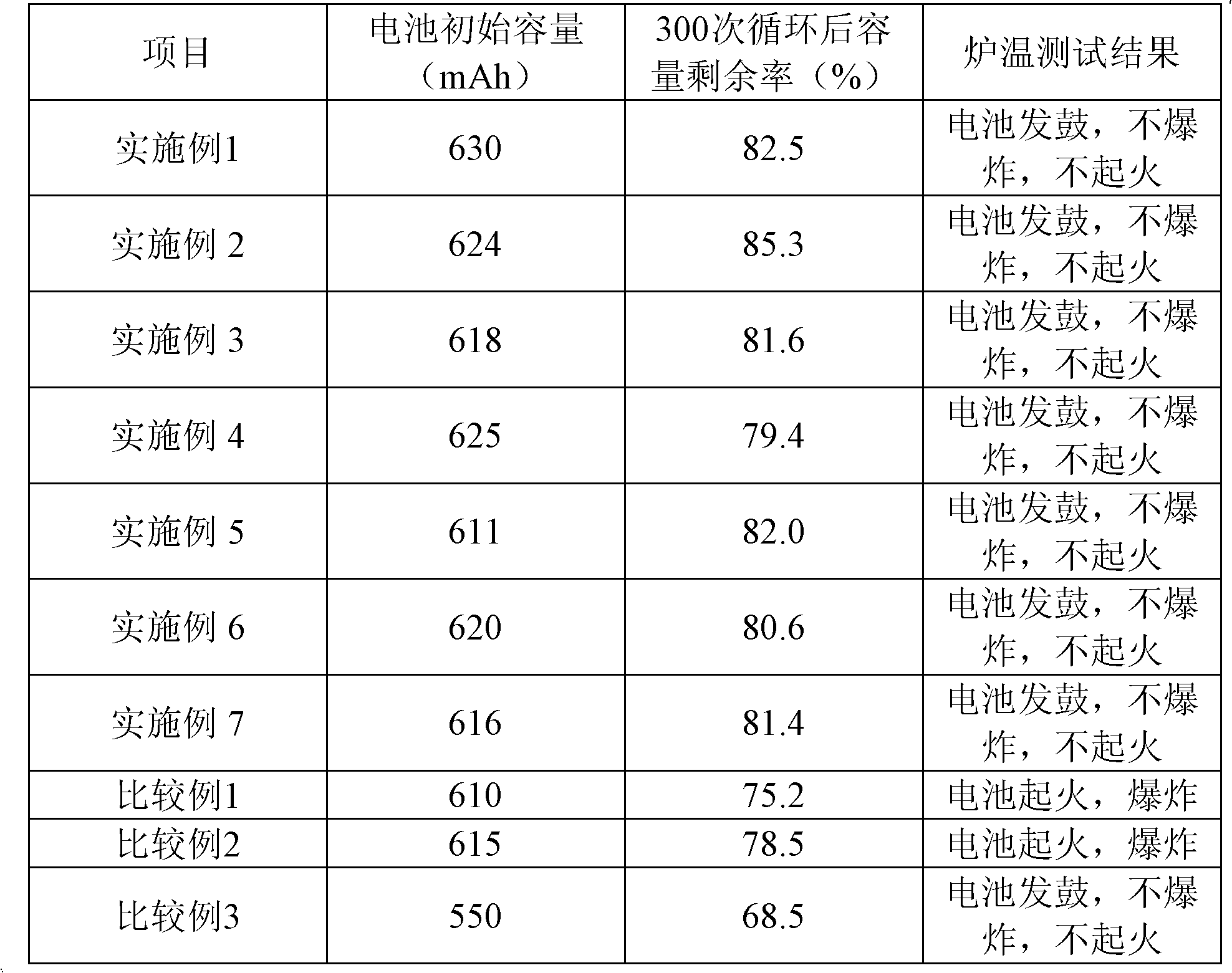

[0045] Electrolyte and battery were prepared in the same manner as in Example 1, except for the selection and content of solvent components in the electrolyte and the type of negative electrode graphite, as shown in Table 1 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com