A kind of electroless nickel plating aging solution treatment process

A technology of electroless nickel plating and treatment process, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of large oxidant consumption, secondary pollution, high price, etc., and achieve high nitrogen and phosphorus content. , protect the environment and achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

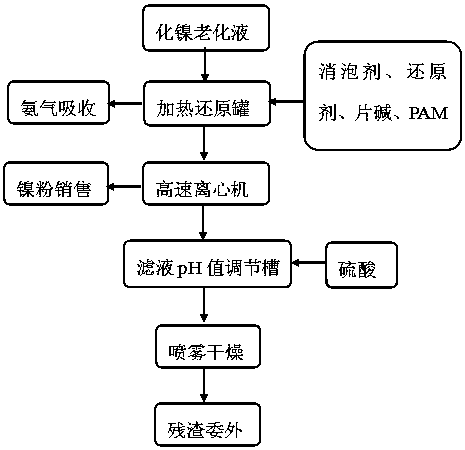

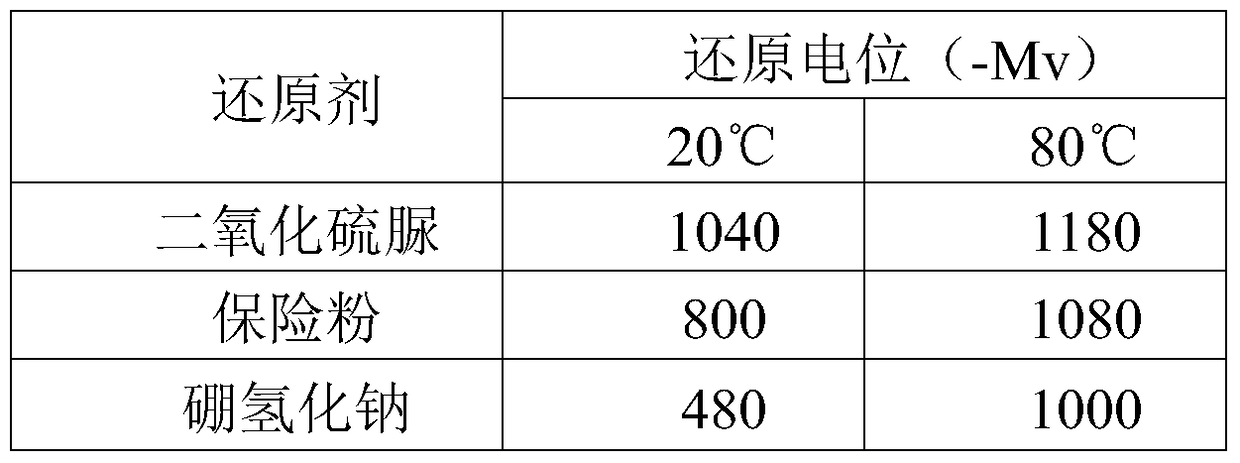

Method used

Image

Examples

Embodiment 1

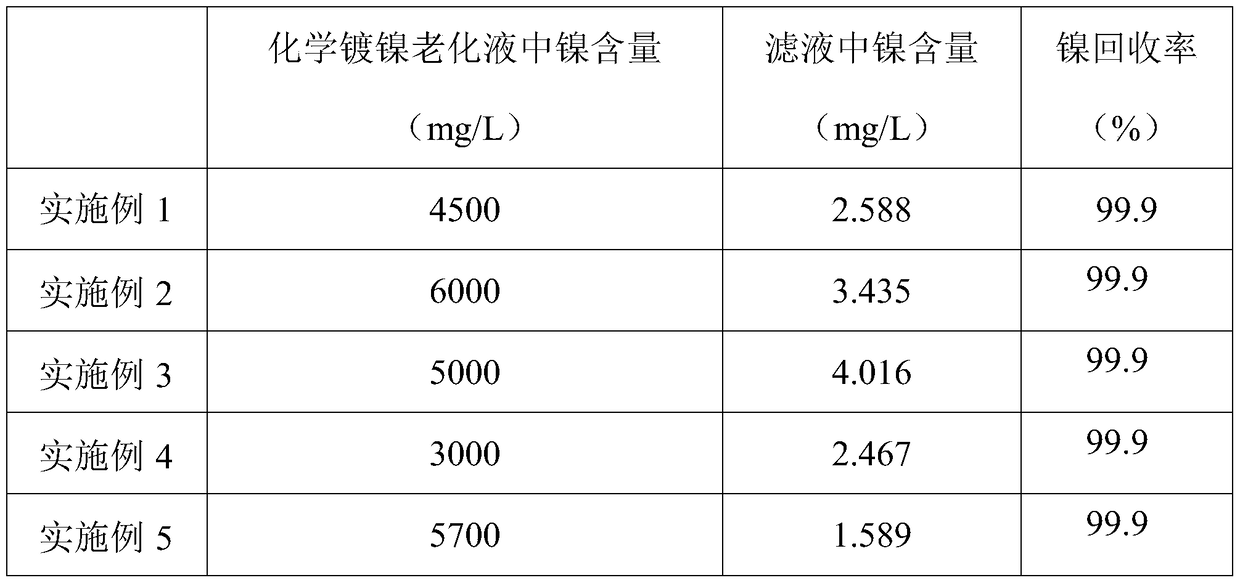

[0044] The electroless nickel plating aging solution (seeing table 1 for its composition list, wherein the nickel content is referring to table 2) is pumped in the heating reduction tank, adds 5mL / L in the described heating reduction tank simultaneously, 10% defoamer and 5.5g / L thiourea dioxide, heated by steam, after the temperature rises to 100°C, add 60g / L caustic soda for reduction reaction, the reaction temperature is 90°C, the pH value is 13, and the reaction time is 30min; Purify, add 3mL / L, 0.1% polyacrylamide after the reaction finishes, obtain nickel powder and filtrate through high-speed centrifugation, nickel powder reclaims, and filtrate (wherein the nickel content sees Table 2) carries out spray drying after adjusting the pH value to 6, obtains The residue belongs to general solid waste, outsourced treatment, to complete the treatment of the aging solution of electroless nickel plating.

Embodiment 2

[0046] The electroless nickel plating aging solution (see Table 1 for its composition list, wherein the nickel content sees Table 2) is pumped into the heating reduction tank, while adding 10mL / L defoamer and 6.5g / L thiourea dioxide in the heating reduction tank , using steam heating, after the temperature rises to 70°C, add 70g / L caustic soda to carry out the reduction reaction, the reaction temperature is 80°C, the pH value is 12, and the reaction time is 20min; the ammonia gas generated during the reaction is purified through the ammonia gas absorption tower, and the reaction After finishing, add 1mL / L, 0.1% polyacrylamide, obtain nickel powder and filtrate through high-speed centrifugation, nickel powder reclaims, and filtrate (wherein nickel content sees Table 2) carries out spray drying after adjusting pH value to 5, and the residue obtained belongs to General solid waste is outsourced to complete the treatment of the electroless nickel plating aging solution.

Embodiment 3

[0048] The electroless nickel plating aging solution (seeing Table 1 for its composition list, wherein the nickel content is referring to Table 2) is pumped in the heating reduction tank, while adding 15mL / L defoamer and 6g / L thiourea dioxide in the heating reduction tank, Heating with steam, after the temperature rises to 90°C, add 65g / L caustic soda for reduction reaction, the reaction temperature is 70°C, the pH value is 14, and the reaction time is 25min; the ammonia gas generated during the reaction is purified through the ammonia gas absorption tower, and the reaction ends Then add 2mL / L, 0.1% polyacrylamide, obtain nickel powder and filtrate through high-speed centrifugation, nickel powder is recovered, and the filtrate (wherein the nickel content is shown in Table 2) is spray-dried after adjusting the pH value to 5, and the residue obtained is general Solid waste is outsourced to complete the treatment of the electroless nickel plating aging solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com