Method for preparing aluminum-iron-carbon micro-electrolysis filler

A technology based on aluminum, iron and carbon, which is applied in the field of new materials for wastewater treatment, can solve the problems of limited removal capacity, low micro-electrolysis potential, and improvement of reduction and oxidation capacity, and achieve the effect of shortening the reaction time and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

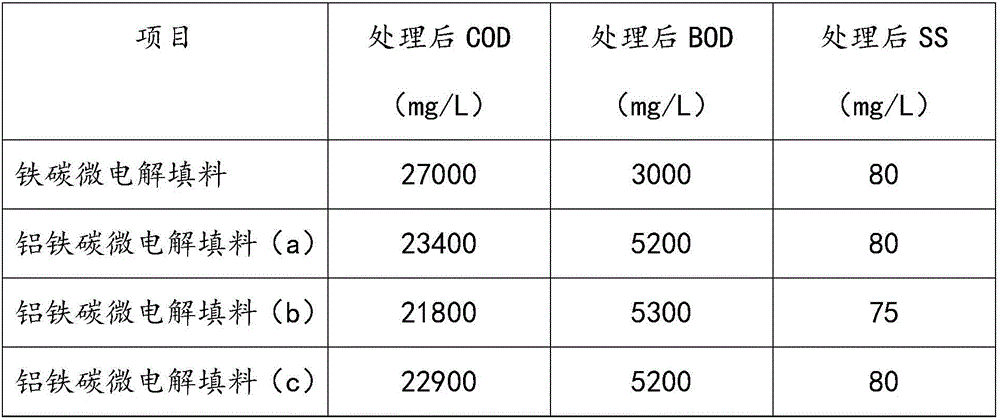

Embodiment 1

[0022] Weigh 1000g of fine iron powder and 200g of coal coke powder with a total iron content of 54%, mix them evenly with a mixer, send them to a reduction furnace for calcination at 500°C, and perform a reduction reaction for 1 hour, take them out after cooling, and use a mechanical pulverizer to obtain Crush the high-carbon iron to about 20 mesh for later use; take 800g of aluminum ingot, put it into the melting furnace, pass helium gas as a protective gas during the melting process, heat up to about 670°C to melt the aluminum ingot, and add the prepared 20 mesh 900g of high-carbon iron powder, mixed evenly, and cooled naturally for about 10 minutes to obtain an aluminum-iron-carbon microporous block, the density of which was taken out was about 1.8g / cm 3 . The aluminum-iron-carbon microporous block is first cut into strips, and then cut into cube-shaped fillers with a length of about 3.0 cm, which is the finished aluminum-iron-carbon micro-electrolytic filler (a). The com...

Embodiment 2

[0024] Weigh 1000g of fine iron powder and 400g of coal coke powder with a total iron content of 60%, mix them evenly with a stirrer, send them into a reduction furnace for calcination at 300°C, and perform a reduction reaction for 1.5 hours, take them out after cooling, and use a mechanical pulverizer to obtain crush the high-carbon iron into about 50 mesh for later use; take 1200g of aluminum ingot, put it into the melting furnace, pass helium gas as a protective gas during the melting process, heat up to about 665°C to melt the aluminum ingot, and add the prepared 50 mesh 2400g of high-carbon iron powder, mixed evenly, and cooled naturally for about 20 minutes to obtain an aluminum-iron-carbon microporous block, the density of which was taken out was about 1.5g / cm 3 . The aluminum-iron-carbon microporous block is first cut into strips, and then cut into cube-shaped fillers with a length of about 8.0 cm, which is the finished aluminum-iron-carbon micro-electrolytic filler (b...

Embodiment 3

[0026] Weigh 1000g of fine iron powder and 800g of coal coke powder with a total iron content of 64%, mix them evenly with a stirrer, send them into a reduction furnace for calcination at 1000°C, and perform a reduction reaction for 0.5 hours, take them out after cooling, and use a mechanical pulverizer to obtain crush the high-carbon iron to about 80 mesh for later use; take 3000g of aluminum ingot, put it into the melting furnace, pass helium gas as a protective gas during the melting process, heat up to about 661°C to melt the aluminum ingot, and add the prepared 80 mesh 1500g of high-carbon iron powder, mixed evenly, and cooled naturally for about 30 minutes to obtain an aluminum-iron-carbon microporous block, the density of which was taken out was about 1.1g / cm 3 . The aluminum-iron-carbon microporous block is first cut into strips, and then continued to be cut into cube-shaped fillers with a length of about 12.0 cm, which is the finished aluminum-iron-carbon micro-electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com