Silver alloy reflecting film with high conductivity and electrochemical corrosion resisting performance and manufacture method thereof

A technology with high conductivity and chemical corrosion, which is applied in the coating process and coating of metal materials, can solve the problem of high energy consumption, and achieve the effect of simple preparation process, high reduction potential and excellent conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation method of silver alloy reflective film, the steps are:

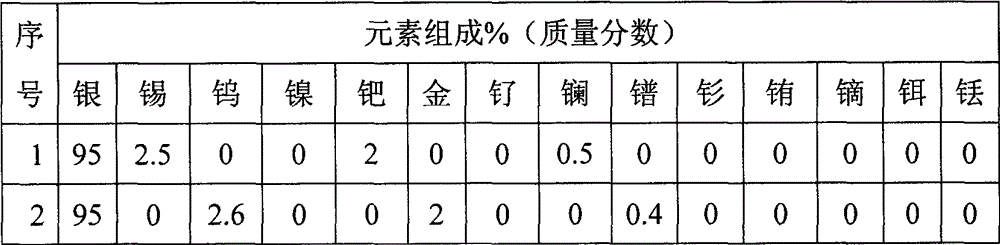

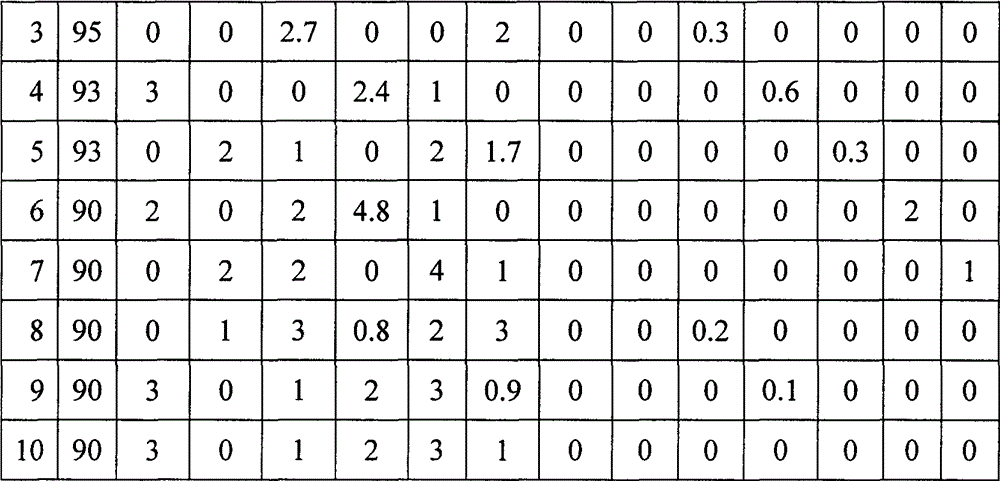

[0024] A glass sheet is used as the substrate 1, and chromium, aluminum, titanium, silicon dioxide, nickel or iron is used as the transition layer 2, and the silver element with a purity of 99.99% and a purity of 99.5% are 0.0001 to 15 parts by mass. Rare earth elements, mixed, and vacuum alloy melting are used to make the required target material, and then a layer of amorphous silver alloy reflective film is plated on the transition layer, that is, the preparation process of the amorphous silver alloy reflective film 3 is completed;

[0025] When the above-mentioned amorphous silver alloy reflective film is also added with 0.001 to 25 parts by mass of one or more elements in iron, cobalt, nickel, tungsten, tin, palladium, gold, rhodium, iridium and ruthenium When, one or more elements in chromium, silicon, aluminum, titanium, iron, cobalt, nickel, tungsten, tin, palladium, gold, rhodium, iridium, ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com