Lithium-ion electrolyte for improving interface of lithium ion pole piece

A technology of lithium ion and electrolyte, which is applied in the field of lithium ion electrolyte to improve the interface of lithium ion pole pieces, can solve problems such as safety risks, inability to fully embed lithium ions, and decrease in mass transfer and conduction speed, so as to improve safety performance and electrochemical performance, prolong the service life of charge and discharge cycles, and reduce the effect of lithium precipitation on charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

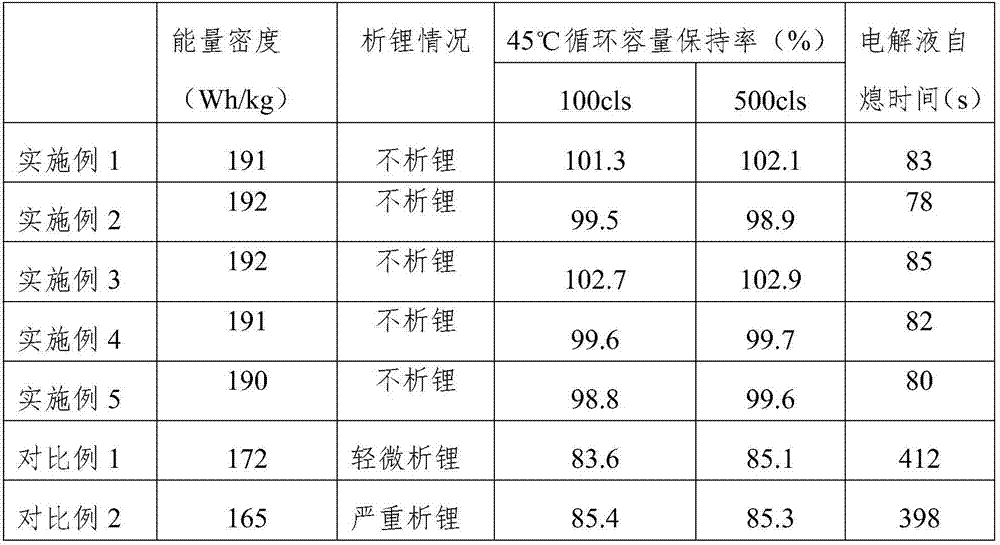

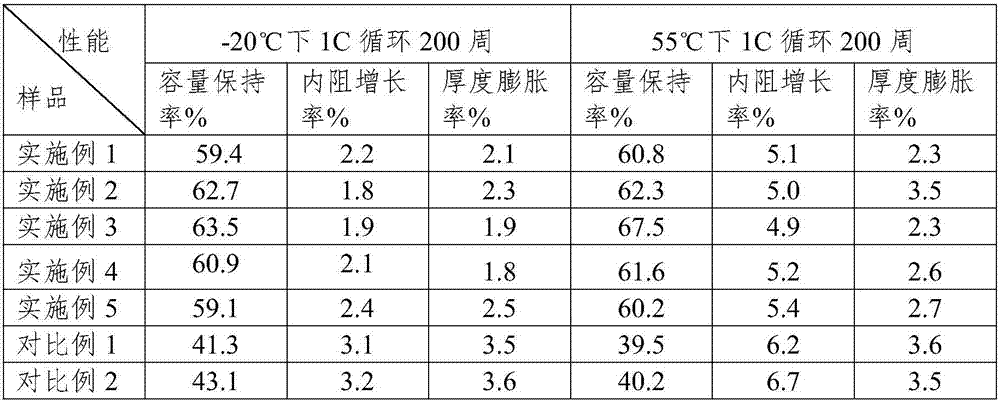

Examples

Embodiment 1

[0022] In this embodiment, the preparation of the lithium ion electrolyte solution for improving the interface of the lithium ion pole piece is as follows:

[0023] In a glove box (moisture <10ppm, oxygen content <1ppm) full of argon, configure an organic solvent, with a purity of 98.92% ditrichloromethyl carbonate 25%, a purity of 99.67% diethyl carbonate 50%, a purity Mix 25% of 98.92% ether compound 1.2-dimethoxyethane, and stir evenly to obtain an organic solvent. Slowly add 83.5% of the total mass of the lithium-ion battery electrolyte into the organic solvent that accounts for the lithium-ion battery electrolyte The percentage of the total mass of the solution is 15% of the lithium salt complexed lithium borate, and then slowly adding the additive 1,4-butane sultone accounting for 1.5% of the total mass of the lithium-ion battery electrolyte, stirring under a carbon dioxide atmosphere Until it is completely dissolved, the lithium ion electrolyte of Example 1 is obtained....

Embodiment 2

[0025] In this embodiment, the preparation of the lithium ion electrolyte solution for improving the interface of the lithium ion pole piece is as follows:

[0026] In a glove box (moisture <10ppm, oxygen content <1ppm) filled with argon gas, an organic solvent is configured, and the purity is 98.92% fluoroethylene carbonate 55%, the purity is 99.67% diethyl carbonate 20%, the purity is 98.92% % ether compound dioxolane 25% mixes, stirs evenly, obtains the organic solvent, gets the percentage that accounts for the total mass of lithium-ion battery electrolyte and is slowly added in the organic solvent that accounts for 67% of the total mass of lithium-ion battery electrolyte. 27% lithium perchlorate, and then slowly add vinylene carbonate accounting for 6% of the total mass of the lithium-ion battery electrolyte, and stir until it is completely dissolved to obtain the lithium-ion electrolyte of Example 2.

Embodiment 3

[0028] In this embodiment, the preparation of the lithium ion electrolyte solution for improving the interface of the lithium ion pole piece is as follows:

[0029] In a glove box (moisture <10ppm, oxygen <1ppm) filled with argon gas, an organic solvent is configured, and the purity is 98.92% cyclic carbonate 45%, the purity is 99.67% diethyl carbonate 30%, the purity is 98.92% Ether compound 25% is mixed, stirs evenly, obtains organic solvent, (wherein, cyclic carbonate is ditrichloromethyl carbonate, fluoroethylene carbonate, ethylene carbonate, ethyl methyl carbonate by weight ratio 1 : 1:1:1 mixed, the ether compound is dioxolane, 1.2-dimethoxyethane, ethylene glycol dimethyl ether mixed in a weight ratio of 1:1:1), and the lithium The percentage of the total mass of the electrolyte of the lithium-ion battery is 75% of the organic solvent, slowly adding the lithium salt that accounts for 20% of the total mass of the electrolyte of the lithium-ion battery, and then slowly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com