A kind of PD/C catalyst and preparation method for TMBQ hydrogenation production TMHQ

A catalyst and activated carbon technology, which is applied in the field of Pd/C catalyst and its preparation, can solve the problems of low catalytic activity, low dispersion of precious metal Pd, and high dispersion, and achieve high catalytic activity, increased reduction potential, and high dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 20g powder, specific surface area greater than 1000m 2 The coconut shell-type activated carbon with a concentration of 5wt.% was refluxed in a water bath at 60°C for 2h with a concentration of 5wt.%, then repeatedly washed with deionized water to neutrality, and then air-dried at 80°C for 4h for later use.

[0040] Preparation of Pd source impregnation solution, weigh about 3g of PdCl 2 The solid was added to 7.29ml of concentrated hydrochloric acid, and after being completely dissolved, it was diluted with deionized water to a 50ml volumetric flask for later use.

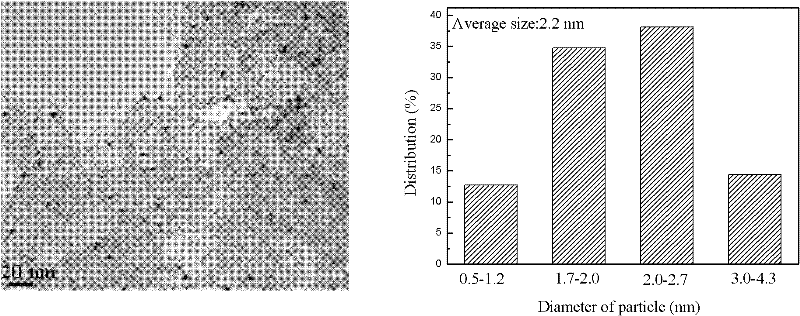

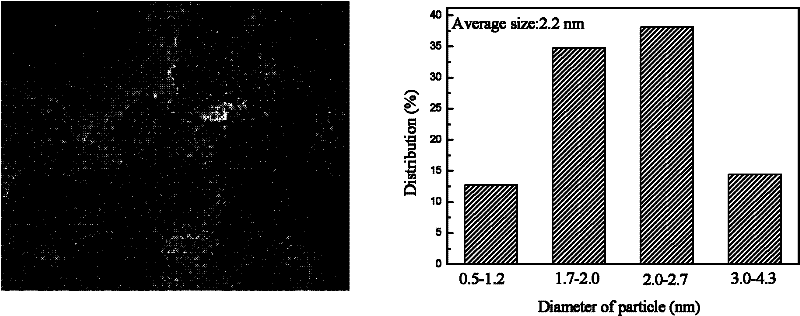

[0041] Take 3 g of pretreated activated carbon and add 10 ml of sodium carbonate with a concentration of 0.9 mol / L to pre-soak the activated carbon for 0.5 h. According to the loading of Pd is 5.0wt.%, pipette PdCl 2 About 14ml of the solution was added to pre-soaked activated carbon and soaked for 6h, and then placed in an oven at 50°C overnight, in 10vol.%H 2 / Ar (total flow rate: 30ml / min) atmosphere a...

Embodiment 2

[0045] 20g powder, specific surface area greater than 1000m 2 The activated carbon per g was refluxed with 5wt.% nitric acid in a water bath at 60°C for 2h, then repeatedly washed with deionized water until neutral, and then air-dried at 80°C for 4h for later use.

[0046] Preparation of Pd source impregnation solution, weigh about 3g of PdCl 2 The solid was added to 7.29ml of concentrated hydrochloric acid, and after being completely dissolved, it was diluted with deionized water to a 50ml volumetric flask for later use.

[0047] Take 3 g of pretreated activated carbon and add 10 ml of oxalic acid with a concentration of 0.1 mol / L to pre-soak the activated carbon for 0.5 h. According to the loading of Pd is 5.0wt%, pipette PdCl 2 About 14ml of the solution was added to pre-soaked activated carbon and soaked for 6h, and then placed in an oven at 50°C overnight, in 10vol.%H 2 / Ar (total flow rate: 30ml / min) atmosphere at 200°C for 2h to obtain the catalyst, and the dispersio...

Embodiment 3

[0051] 20g powder, specific surface area greater than 1000m 2 The coconut shell-type activated carbon with a concentration of 10wt.% was refluxed in a water bath at 60°C for 2h with a concentration of 10wt.%, then repeatedly washed with deionized water to neutrality, and then air-dried at 80°C for 4h for later use.

[0052] Preparation of Pd source impregnation solution, weigh about 3g of PdCl 2 The solid was added to 7.29ml of concentrated hydrochloric acid, and after being completely dissolved, it was diluted with deionized water to a 50ml volumetric flask for later use.

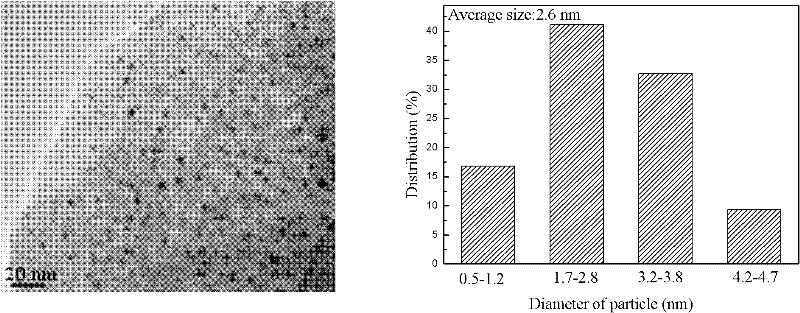

[0053] Take 3 g of pretreated activated carbon and add 10 ml of oxalic acid with a concentration of 0.1 mol / L to pre-soak the activated carbon for 0.5 h. According to the loading of Pd is 5.0wt%, pipette PdCl 2 About 14ml of the solution was added to pre-soaked activated carbon and soaked for 6h, and then placed in an oven at 50°C overnight, in 10vol.%H 2 / Ar (total flow rate: 30ml / min) atmosphere at 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com