Preparation method of lithium ion battery pole piece

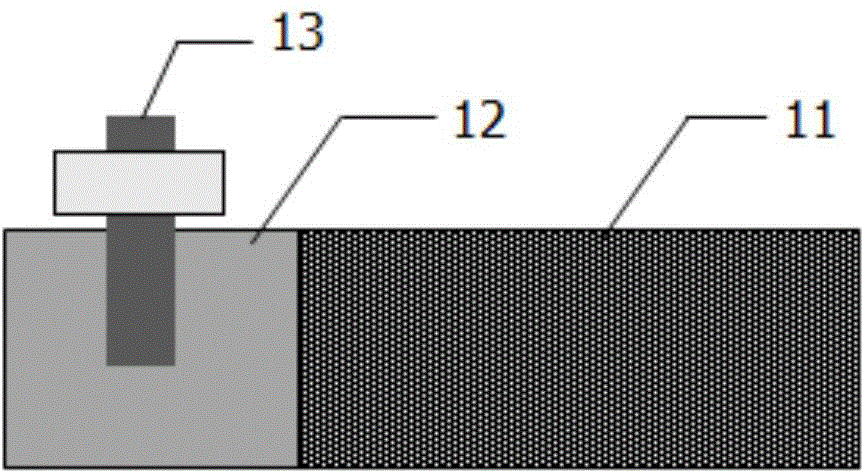

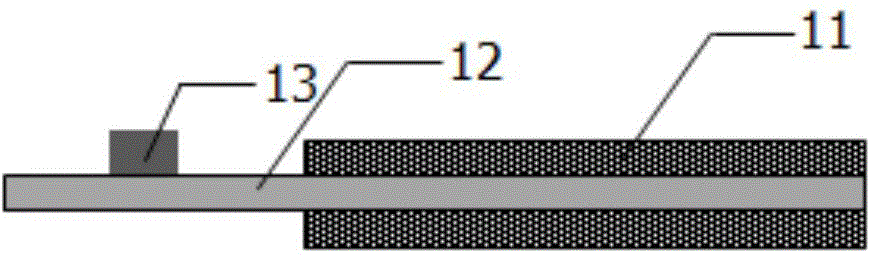

A lithium ion battery and pole piece technology is applied in the field of preparation of lithium ion battery pole pieces, and can solve the problems of low area utilization rate of current collector 12, reduced battery pole piece area utilization rate, low volume energy density of lithium ion battery, etc. Achieve the effect of reducing increase, low battery internal resistance, and high volumetric energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Install a single-sided automatic glue-applying mechanism between the unwinding and coating head of the extrusion coating machine, and automatically paste a 25mm wide, 10mm long, and 70μm thick glue on the fixed position of the current collector according to the designed coating size. Thermally expandable foam release acrylic pressure sensitive tape. In the heat-expandable foamable peelable acrylate pressure-sensitive adhesive tape used: the thickness of the heat-expandable foamable peelable acrylate pressure-sensitive adhesive is 50 μm, the particle size of the expanded foamed microspheres is 20-40 μm, and the foaming expansion temperature is at 100-130°C, the volume expansion of the expanded microspheres is 50-150 times during the thermal foaming process; the thickness of the matrix resin film is 20 μm, and the matrix resin film is polyester polyethylene terephthalate; this The peeling strength of the pressure-sensitive adhesive tape to copper foil or aluminum foil ...

Embodiment 2

[0041] Using the same automatic glue-applying mechanism, the heat-expandable foaming peelable acrylic pressure-sensitive tape is pre-attached to one side of the positive electrode current collector or the negative electrode current collector according to the above size. Then carry out the extrusion coating of positive electrode active material slurry or negative electrode active material slurry. After the coated film enters the oven for drying, use the temperature of the oven (80-150° C.) to thermally foam and peel off the adhesive tape to realize heating. Foaming and removing the slurry coated on the upper layer, so as to realize the welding hollow area reserved for the single membrane sheet layer, and the welding hollow area of the symmetrical surface is implemented in the same way. The difference between this embodiment and embodiment 1 is: embodiment 1 is coating while pasting glue, and this embodiment is pasting film in advance, and then coating.

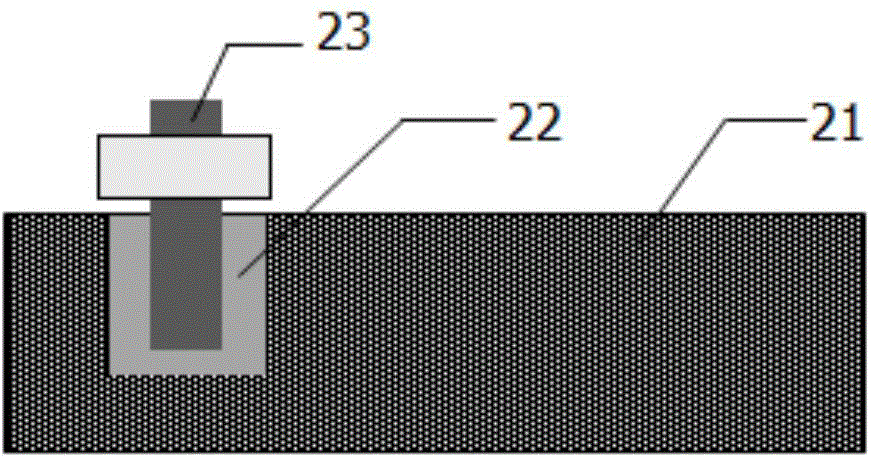

Embodiment 3

[0043] 1) Spray or print a heat-expandable foaming peelable acrylate adhesive equal to the area of the preset hollowed-out area on the corresponding positions of the positive and negative current collectors. Among them, the thickness of the heat-expandable foamable peelable acrylate adhesive is 70 μm, the particle size of the foamed and expanded microspheres is 20-40 μm, and the expansion temperature of the expanded microspheres is 100-130° C. The multiple is 50 to 150 times, and the peel strength of the adhesive layer to copper foil or aluminum foil at room temperature is ≥10N / m.

[0044] 2) to 4) are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com